Sour Water Recovery Unit

مهر ۱۱, ۱۴۰۳

How is Aspen Plus Training?

مهر ۱۱, ۱۴۰۳Introduction

The Sulfurox process is a method used for the sweetening of sour hydrocarbons, particularly to remove sulfur compounds like mercaptans from streams of gas or liquid hydrocarbons. This process is particularly valuable in the oil and gas industry, where the quality of products must meet stringent environmental and market standards.

Key Features of the Sulfurox Process:

- Chemical Reactions: The Sulfurox process typically involves the conversion of mercaptans (such as methyl mercaptan and ethyl mercaptan) into more stable compounds (mercaptides) through a series of chemical reactions. These reactions often involve the use of caustic solutions and catalysts to facilitate the transformation.

- Separation Techniques: The process usually incorporates liquid-liquid extraction columns where sour hydrocarbons contact a caustic solution. The mercaptans are absorbed into the caustic solution, while the sweetened product is collected after appropriate treatments.

- Application: The sweetened butane produced from the Sulfurox process is suitable for a range of applications including petrochemical feedstock and fuel.

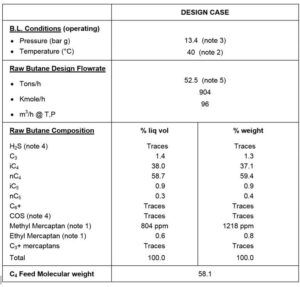

Unit 115 Phase 9 and 10 of South Pars (Butane Sweetening via Sulfurox Method)

In Unit 115, there is an extraction column with 15 trays where methyl mercaptan and ethyl mercaptan are converted into mercaptide according to Reaction (1). Sour butane enters the bottom of the column and comes into contact with a caustic solution from Unit 113 (the caustic recovery unit), which contains 100 ppm wt of the LCPS-30 catalyst (liquid form injected into the system from Unit 113) in a non-concurrent liquid-liquid setup.

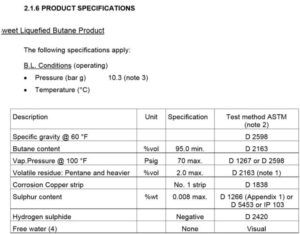

The sweetened butane then enters the settler, where it is washed with water before entering. Finally, after passing through a sand filter to prevent the caustic solution from carrying over with the sweetened butane, it proceeds to the butane dehydration unit.

The butane dehydration unit operates similarly to the propane dehydration unit. Additionally, the simulation of the Sulfurox unit in Unit 114 of South Pars has been conducted using Hysis software.