Principles of Design Laboratory Scaffolding and Clean Room

آذر ۱۴, ۱۴۰۳

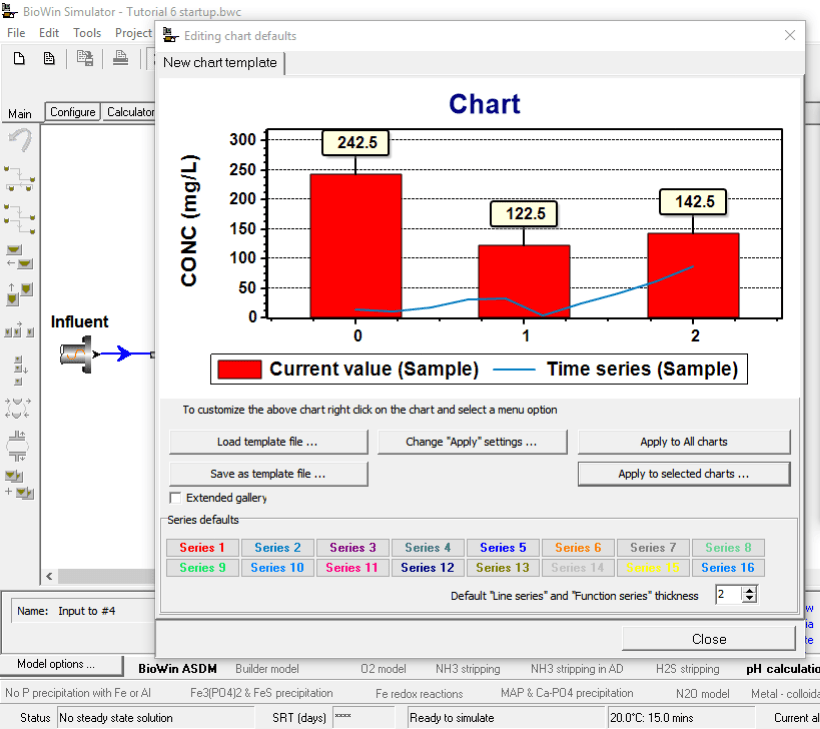

BioWin is a Software for Simulating Wastewater Treatment

آذر ۱۶, ۱۴۰۳Introduction

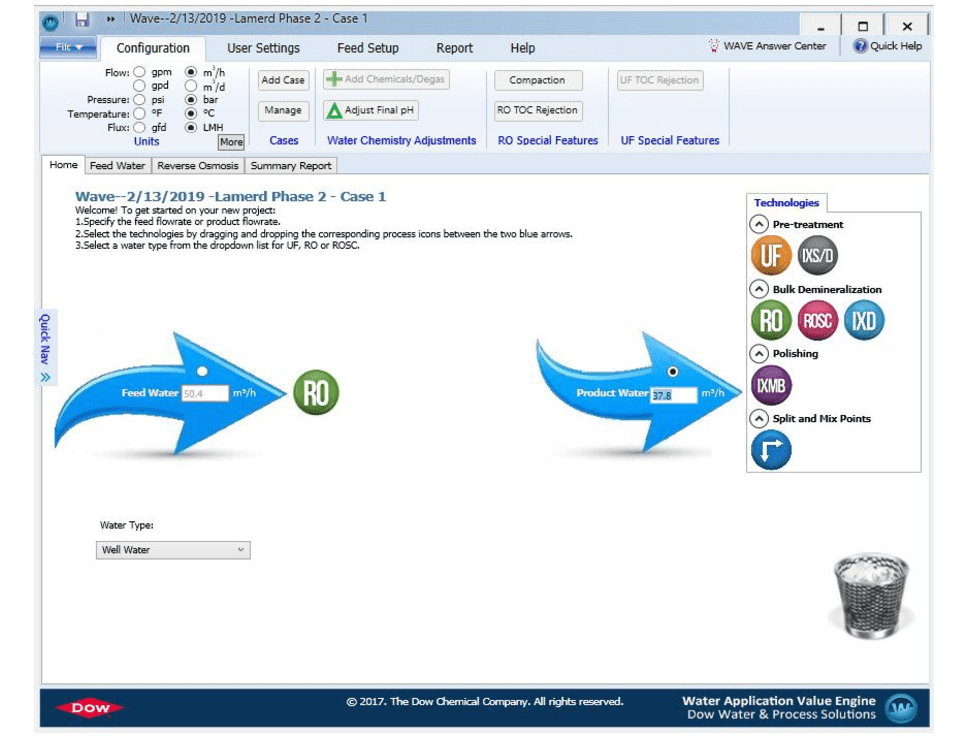

Wave software is a powerful tool for designing and simulating water treatment systems, developed by DuPont Water Solutions. It is particularly useful for engineers and designers working with advanced water treatment technologies such as reverse osmosis (RO), ultrafiltration (UF), and nanofiltration (NF).

Wave provides a comprehensive simulation environment that allows users to accurately predict the performance of water treatment systems and create optimized and cost-effective designs. By focusing on reducing costs, increasing efficiency, and improving the quality of produced water, Wave helps users to execute their projects with greater confidence.

Wave’s User Interface

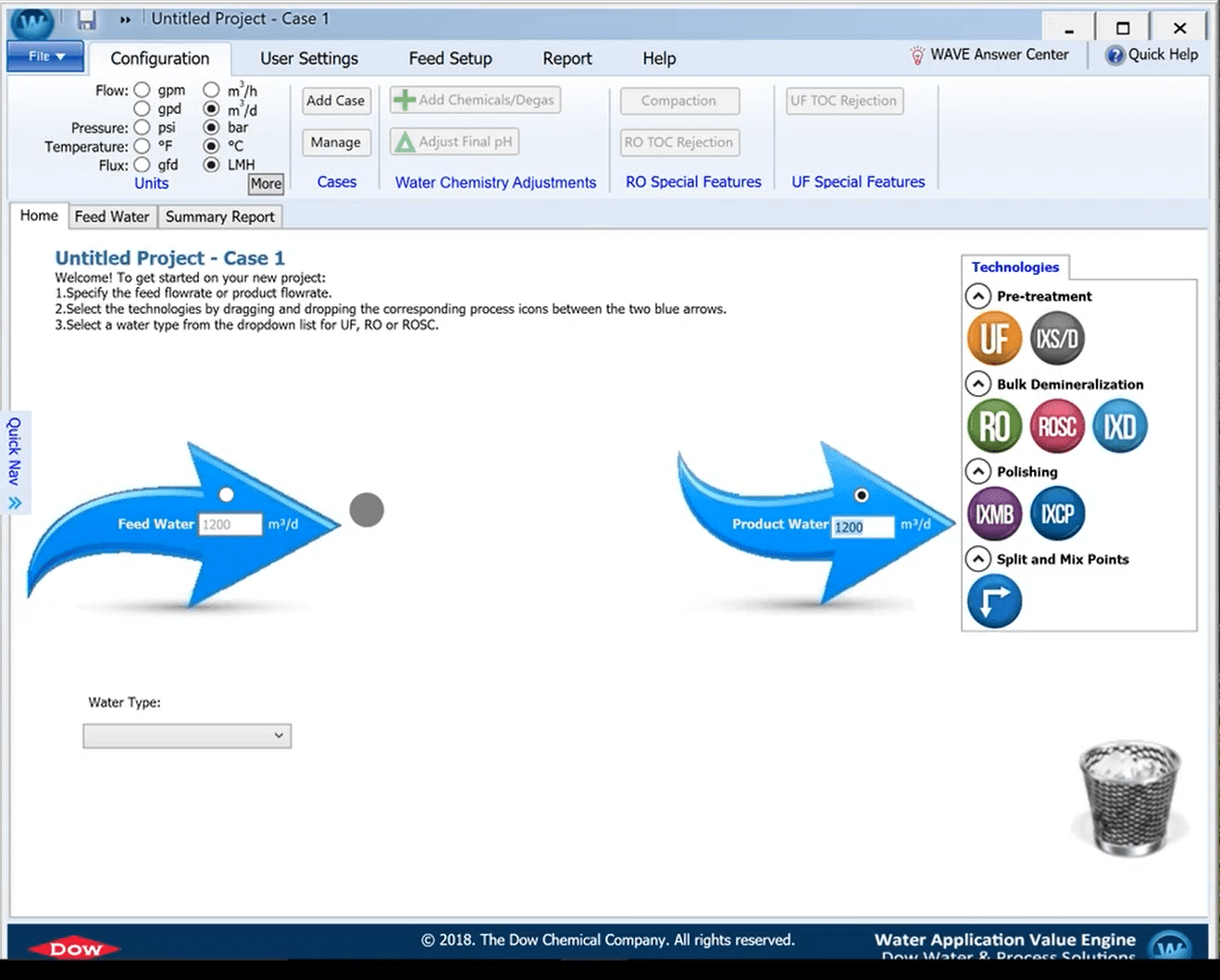

Wave provides a sophisticated graphical interface designed to simplify the design and simulation process. The software’s main dashboard offers a comprehensive overview of the project, including project name, process type, and initial parameters. Users can manage all their projects from this central hub.

Key features within Wave’s interface include:

- System Design: Users can visually construct process diagrams by adding membranes, pumps, and other equipment, and then customize their parameters.

- Analysis Tools: Wave allows users to visualize and analyze simulation results through graphs and tables.

- Equipment Database: This section contains comprehensive information about various membranes and equipment, ready for users to incorporate into their designs.

- Reporting: The software generates detailed reports on simulation results, including system performance and economic data.

Advantages and Disadvantages of Wave Software

Advantages:

- High Simulation Accuracy: Wave employs advanced algorithms to predict membrane performance, resulting in highly accurate simulation results.

- User-Friendly Interface: One of Wave’s standout features is its intuitive and visually appealing interface, simplifying the design and simulation process.

- Powerful Analytical Tools: Wave provides tools for analyzing energy consumption, operating costs, and performance parameters to optimize system design.

- Equipment Flexibility: Users can select from a wide range of membranes and equipment in the software’s database and model them in their system.

- Reduced Design Costs: By using Wave, users can validate their designs before implementation, preventing costly errors.

Disadvantages:

- Requires Accurate Input Data: To achieve precise simulations, users must provide accurate data on feedwater composition and operating parameters.

- Limited Support for Specific Processes: While Wave covers many filtration processes, it may have limitations in simulating certain specialized processes.

- Database Dependency: Although the software’s database is extensive, specific equipment or membranes may not be available.

- Software License Cost: Some users may find the cost of using the software to be high, especially compared to free alternatives.

Wave Software Simulation

Wave (Water Application Value Engine) is one of the most powerful tools available for simulating water treatment processes, developed by DuPont. This software provides capabilities that allow users to accurately model the design and performance of water filtration systems. Simulation in Wave is a comprehensive and step-by-step process that enables designers and engineers to ensure system efficiency, reduce costs, and prevent potential design and implementation problems.

Simulation Process in Wave

1.Project Definition and Initial Data Input

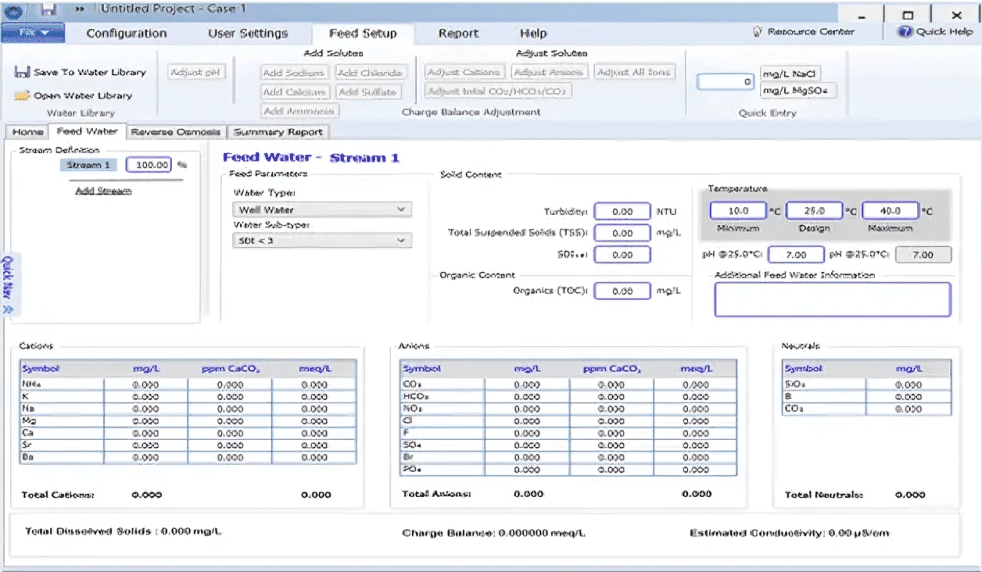

The first step in using Wave is to define the project and enter the initial data. This information includes feedwater specifications, the type of treatment process, and operational requirements. Initial data plays a crucial role in simulation accuracy and includes parameters such as:

-

- Feedwater chemical composition: Concentrations of ions and dissolved substances like calcium, magnesium, nitrate, and chloride.

- Water temperature: Feedwater temperature significantly impacts membrane performance.

- TDS (Total Dissolved Solids): Salinity level or concentration of dissolved substances in water.

- pH: Acidity or alkalinity of the feedwater.

- Turbidity and water quality: Determines the type of pretreatment required. Wave allows users to manually input this data or utilize a ready-made database.

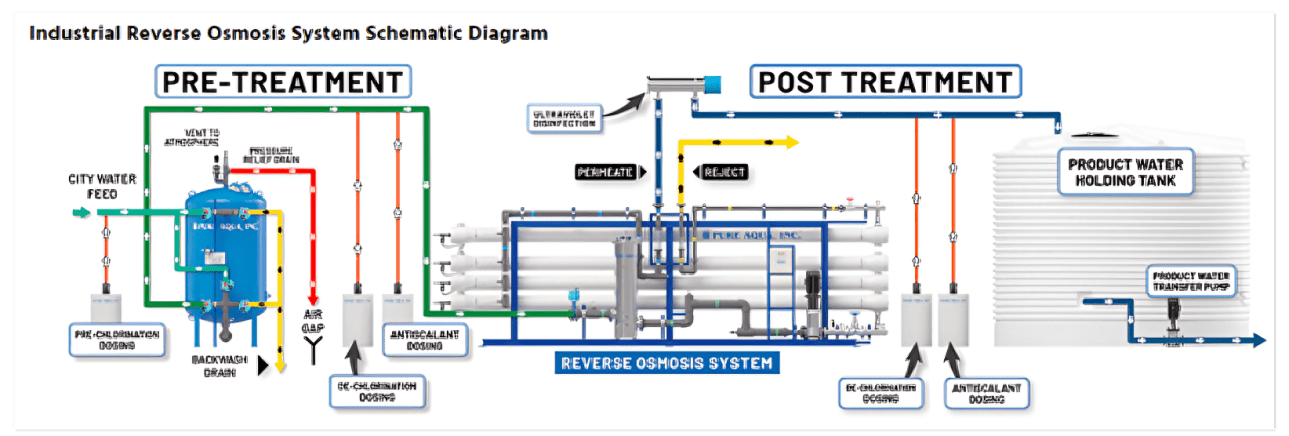

2.Process Selection and Equipment

After entering the initial data, users must select the appropriate treatment process. Wave supports a wide range of treatment processes, including:

- Reverse osmosis (RO): For removing salts and dissolved solids from seawater or brackish water.

- Nanofiltration (NF): For removing multivalent ions and certain organic substances.

- Ultrafiltration (UF): For removing suspended solids and microorganisms.

- Combined processes: Such as UF pretreatment followed by RO.

At this stage, the designer must select suitable equipment such as membranes, pumps, and pretreatment. Wave provides a comprehensive database of various membranes and equipment available on the market, which users can easily access.

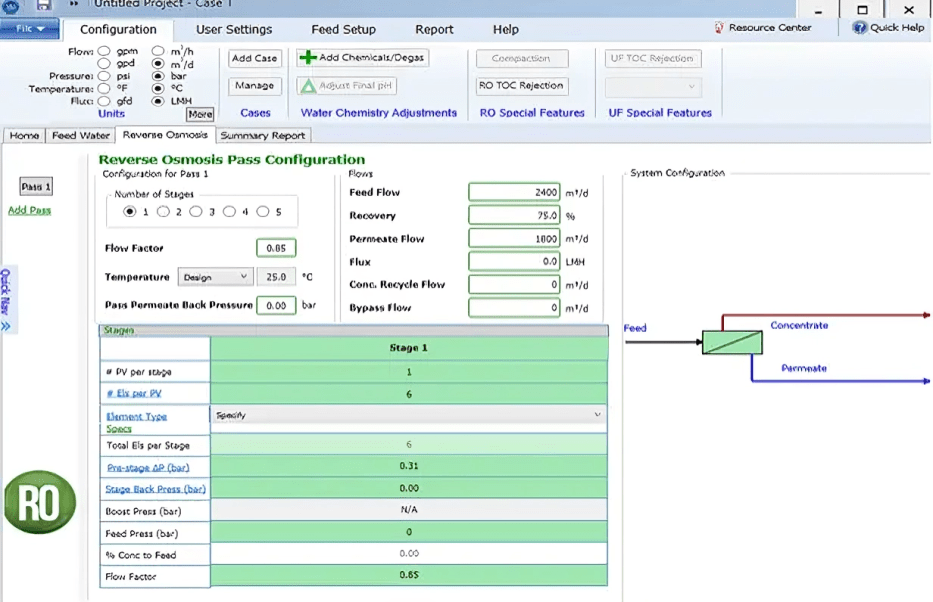

3. Setting Operating Parameters

After selecting the equipment, it is time to set the operating parameters. These parameters determine the performance of the system under different conditions. In Wave software, users can adjust the following values:

- Operating pressure: The pressure required to pass water through the membrane.

- Flow rate: The input and output flow rate.

- Recovery rate: The percentage of treated water relative to the total input water.

- Injected chemicals: Such as anti sealant’s and pH adjusters.

4. Running the Simulation

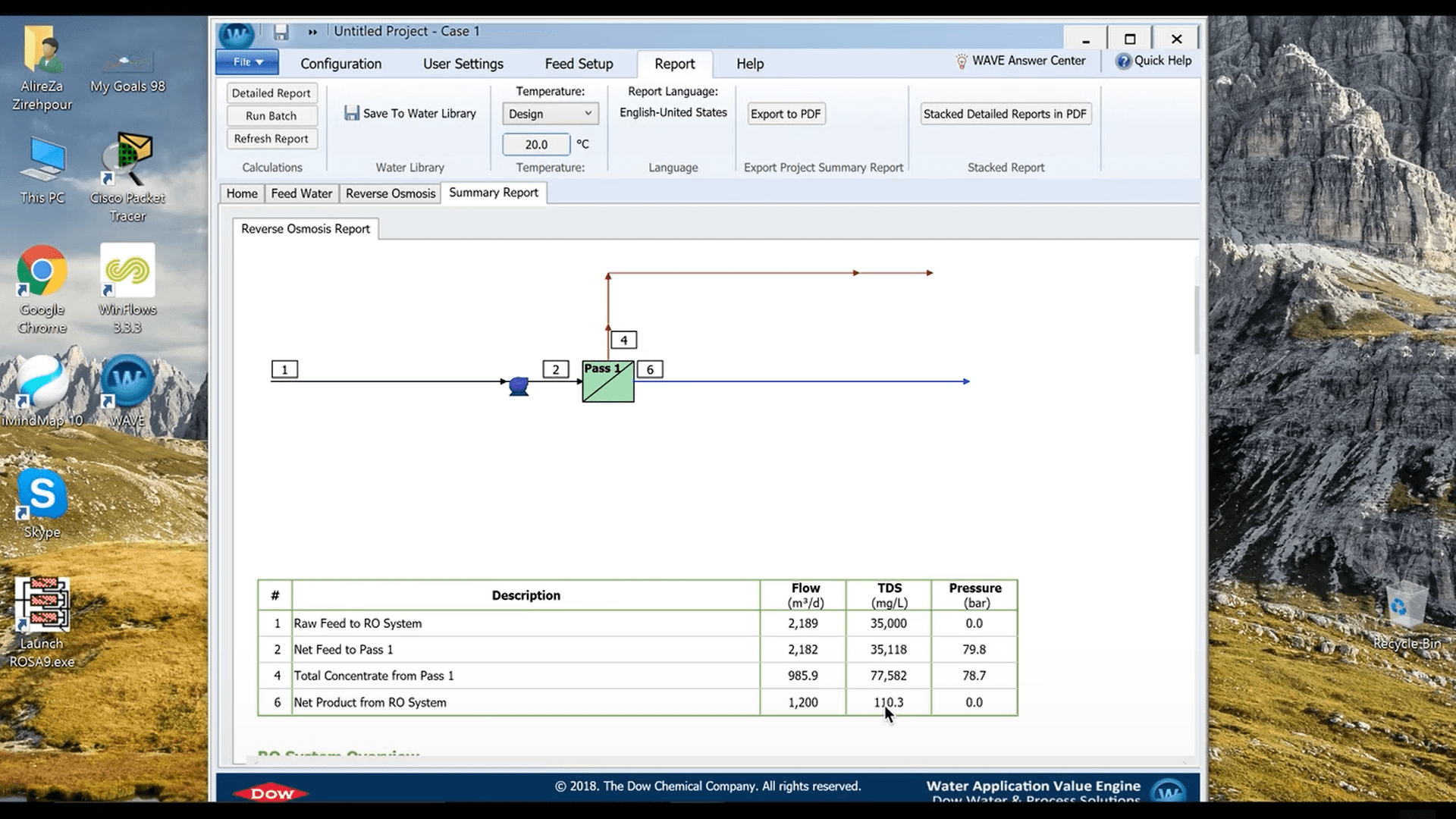

Once the previous steps are completed, users can run the simulation. Wave, using advanced algorithms and the input data, predicts the system’s performance. This prediction includes:

- Purified water quality: Including the concentration of ions and TDS in the output.

- Energy consumption: The amount of energy required for system operation.

- Probability of scaling: The likelihood of scale formation on membranes.

- Membrane life: Predicting the lifespan of membranes based on operating conditions.

Wave provides all this information to users accurately and transparently.

5. Analysis of Simulation Results

One of the outstanding features of Wave is the ability to analyze simulation results. Users can view results in the form of graphs, tables, and comprehensive reports. Some of the viewable results include:

- System efficiency: The percentage of purified water relative to the total input water.

- Operating costs: Including energy costs, chemicals, and maintenance.

- Output water quality: Comparing the quality of the output water with the required standards.

- Chemical consumption: The exact amount of chemicals required for pretreatment and scaling prevention.

These analyses help users make better decisions in the design and operation of treatment systems.

6. Design Optimization

Wave offers a variety of tools for optimizing system design. Users can find the optimal design for their system by changing operational parameters and comparing results. This optimization includes:

- Reducing energy consumption.

- Increasing water recovery rates.

- Decreasing chemical costs.

- Preventing premature membrane failure.

7. Generating Final Reports

Another capability of Wave is the ability to generate accurate and professional reports of simulation results. These reports include all information related to design, performance, and costs and can be used for presentations to clients or for project documentation.

8. Exploring Different Scenarios

Wave allows users to explore different scenarios for varying operational conditions. For example:

- System performance under low-pressure conditions.

- Changes in feed water quality and their impact on system performance.

- Using different membranes and comparing their performance.

Real-world Examples of Successful Wave Usage

Due to its accuracy and efficiency, Wave software has become a primary tool in the design and management of water treatment systems in industrial and municipal projects. In this section, we will examine real-world examples of the successful use of this software in various projects. These examples demonstrate how Wave has helped users achieve optimal designs, reduce costs, and minimize environmental impacts.

1. Water Treatment Project in the Oil and Gas Industry

- Location: Middle East

- Problem: An oil and gas company was facing the challenge of providing suitable water for drilling operations. The available water in the region had high salinity and significant amounts of dissolved solids, which reduced equipment efficiency and increased maintenance costs.

- Solution: Using Wave software, the engineering team was able to design a reverse osmosis (RO) based treatment system. This design involved selecting high-performance membranes and optimizing operating pressure.

- Result:

- Reduced energy consumption by 15%.

- Improved treated water quality with TDS reduced to less than 50 ppm.

- Reduced annual operating costs by 20%.

Here are some practical examples of how Wave has been used to solve real-world water treatment challenges:

2. Urban Water Reclamation in California:

-

- Problem: A small Californian city faced a severe water shortage and sought to increase water recycling. The wastewater, however, contained high levels of nitrates and phosphates, limiting its direct use for agriculture or drinking.

- Solution: Wave was used to design a combined nanofiltration (NF) and reverse osmosis (RO) system. By simulating the process, engineers were able to maximize water recovery rates and minimize the need for chemical pretreatment.

- Results:

- Achieved an 80% wastewater recovery rate.

- Reduced chemical usage by 25%.

- Produced water of agricultural-grade quality.

3. Seawater Desalination for a Small Island:

-

- Problem: A small island relied on seawater desalination for its freshwater supply, but high operational costs and frequent membrane failures were significant challenges.

- Solution: Wave was used to design an RO-based desalination system incorporating optimized pretreatment and antiscalant dosing.

- Results:

- Reduced membrane fouling by 30%.

- Achieved annual operational cost savings of $200,000.

- Provided clean drinking water for 10,000 people.

4. Industrial Water Treatment in a Food Processing Plant:

-

- Problem: A food processing plant experienced frequent membrane fouling, leading to production downtime and increased maintenance costs.

- Solution: Wave was used to simulate the pretreatment process and identify optimal pretreatment conditions and chemical dosing to prevent fouling.

- Results:

- Increased membrane life from 3 to 12 months.

- Reduced chemical usage by 40%.

- Improved overall plant productivity by 15%.

5. Power Plant Water Treatment:

- Problem: A large power plant suffered from corrosion and reduced efficiency due to poor-quality boiler feedwater.

- Solution: Wave was used to design a treatment system combining ultrafiltration (UF) and reverse osmosis. Simulations showed that optimizing operating pressure and recovery rate could significantly reduce costs.

Results:

- Reduced equipment corrosion by 50%.

- Decreased energy consumption by 10%.

- Improved plant efficiency by 5%.

6. Application in Marine Vessels

Scenario: Commercial ships in the Atlantic Ocean. Problem: Providing potable water and industrial water for marine vessels has always been a significant challenge. Utilizing seawater requires complex treatment processes and high energy consumption. Solution: With the aid of Wave, a compact and efficient water treatment system was designed for ships. This system included a suitable pre-treatment stage and specialized membranes that exhibited high performance under varying operational conditions.

Results:

- Reduced equipment weight by 20%.

- Decreased fuel consumption due to reduced load.

- Provided high-quality potable water for the ship’s crew.

7. Agricultural Projects in Africa

Scenario: North Africa. Problem: Farmers in this region required low-salinity water for irrigation, but available water sources were primarily brackish. Solution: Using Wave, a treatment system was designed to convert brackish water into water suitable for irrigation. Simulations demonstrated that by adjusting the recovery rate and operating pressure, costs could be significantly reduced. Results:

- Increased agricultural production by 30%.

- Reduced irrigation costs by 25%.

- Enhanced sustainability in water supply for agriculture.

Comparison of Wastewater Treatment Design and Simulation Software

1. Wave Software

Developed by DuPont Water Solutions, Wave is a comprehensive tool for designing and simulating water treatment processes using various technologies such as reverse osmosis (RO), ion exchange, and nanofiltration (NF) systems.

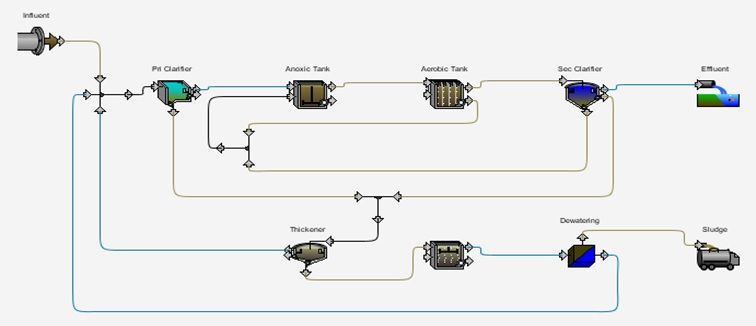

2. BioWin

BioWin software is a powerful tool for simulating wastewater treatment processes developed by EnviroSim. This software allows for accurate modeling of biological, chemical, and physical processes in municipal and industrial wastewater treatment plants.

3. GPS-X

GPS-X software is an advanced tool for modeling and simulating wastewater treatment processes, produced by Hydromantis. This software is suitable for complex projects and research applications due to its high flexibility and the ability to adjust various parameters.

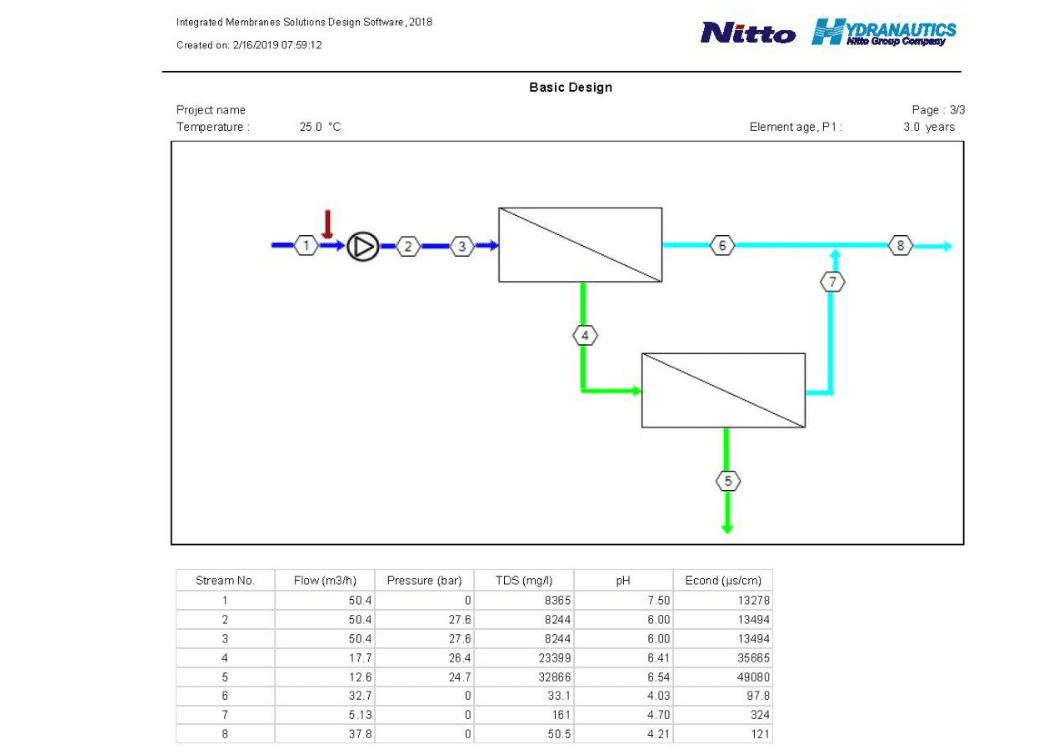

4. IMSDesign

IMSDesign software was developed by Hydranautics for the design of reverse osmosis (RO) systems. This software is mainly used for the selection and design of reverse osmosis membranes in industrial and municipal water treatment systems.

Software Comparison Table

Here’s the translation of the provided table into English in tabular form:

| Features | Wave | IMSDesign | GPS-X | BioWin |

|---|---|---|---|---|

| Main Application | Designing and simulating water treatment processes | Designing reverse osmosis systems | Advanced design and simulation of treatment plants | Simulation of wastewater treatment processes |

| User Interface | Graphic and comprehensive | Simple and focused on membrane design | Graphic with high flexibility | Graphic and user-friendly |

| Suitable For | Designing industrial and municipal water treatment processes | Reverse osmosis systems | Research projects and complex treatment plants | Municipal and industrial treatment plants |

| Required Knowledge | Knowledge of water and chemical treatment processes | Suitable for professional and experienced users | Advanced parameter adjustments expertise | Basic knowledge of treatment processes |

| Unique Features | Support for various water treatment technologies | Extensive database for selecting suitable membranes | High flexibility in detailed process adjustments | Accurate modeling of biological and chemical processes |

| Limitations | Requires expertise in using advanced features | Focused on reverse osmosis system design | Complexity in learning and usage for beginners | Requires additional resources for complex simulations |

| Industrial Application | Designing hybrid water treatment processes | RO system design for large and complex systems | Specialized simulation for large and complex systems | Simulation and optimization of large-scale wastewater plants |

Conclusion

Wave is a comprehensive software tool designed for designing and simulating water treatment systems, including reverse osmosis (RO), ultrafiltration (UF), nanofiltration (NF), and other membrane processes. By providing accurate modeling and adjustable parameters, this software enables engineers to evaluate and optimize system performance before implementation. This capability not only reduces design time but also minimizes errors and costs associated with poor design.

One of the most significant achievements of Wave is its ability to reduce the environmental impact of water treatment systems. By offering tools to reduce energy consumption, chemical usage, and waste, Wave contributes to the conservation of natural resources and pollution reduction. Additionally, Wave allows engineers to design systems with high recovery rates, which reduces the need for new water sources and promotes sustainable water management.