- Introduction Petrochemical units are fundamental components of the petrochemical industry, playing a crucial role in supplying raw materials for various products. Among these processes, ethylene recovery […]

- Introduction The petrochemical industry, as a key economic driver, produces essential raw materials used across various aspects of daily life. Within this sector, cooling processes play […]

- Description The terms PVC and vinyl are commonly used not only to refer to polymers but also to all materials where polyvinyl chloride (PVC) is a […]

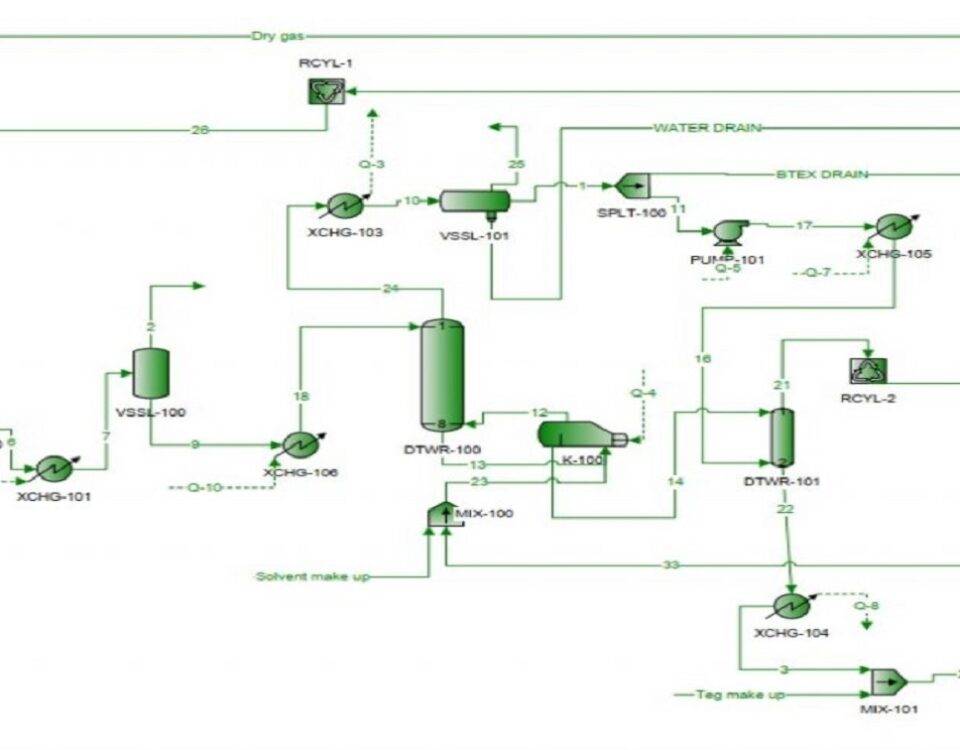

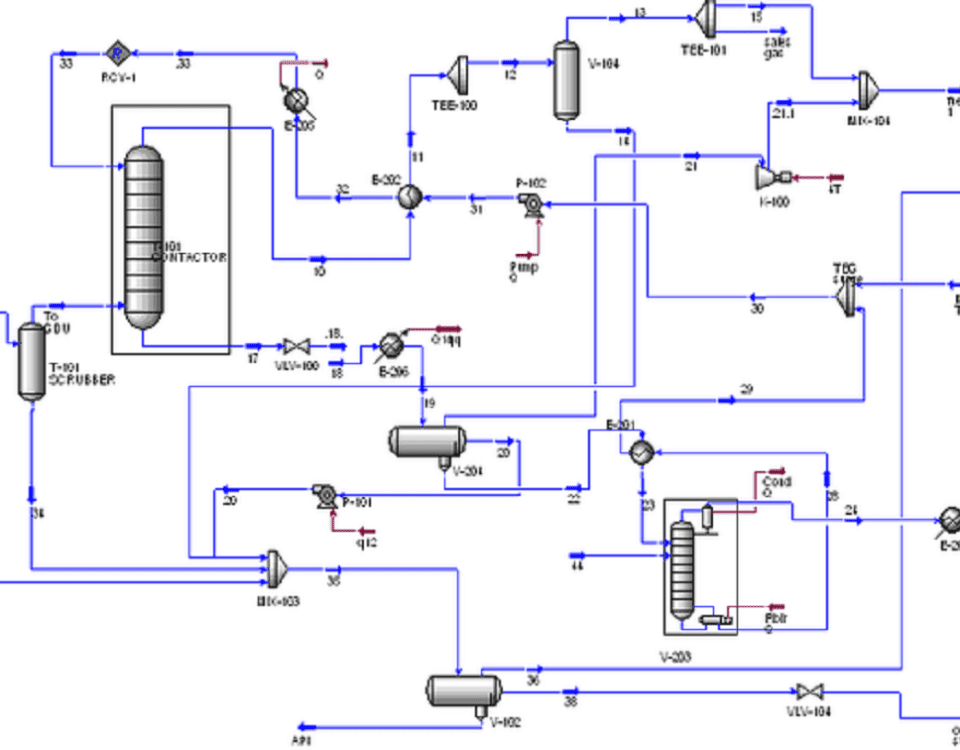

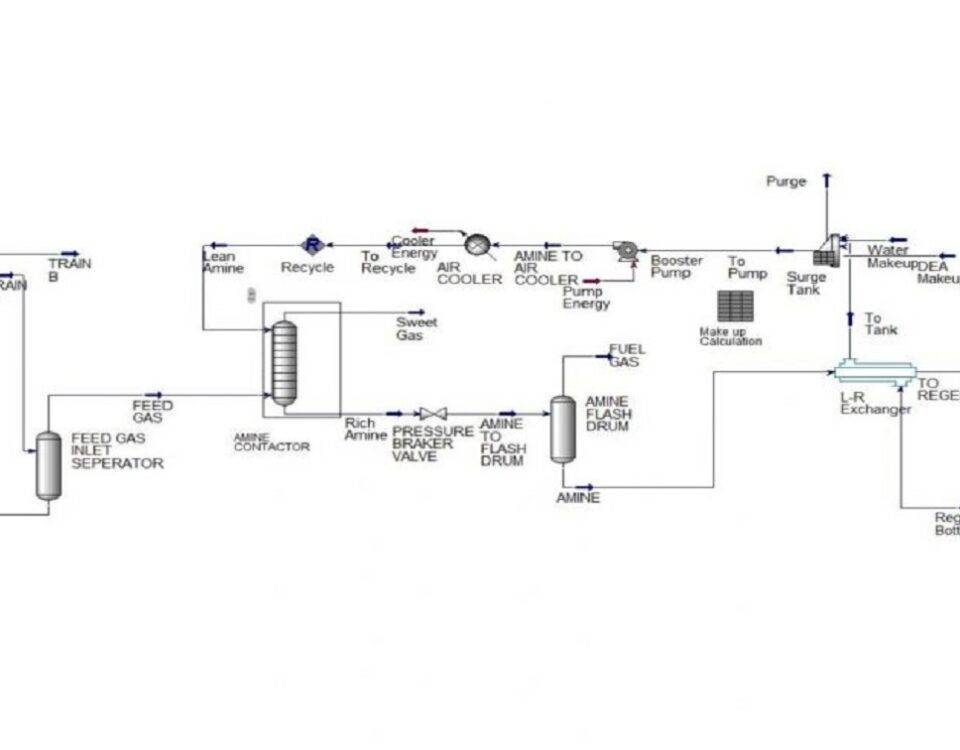

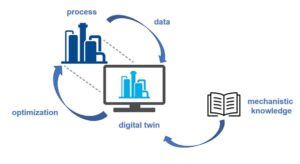

- Introduction The simulation of the natural gas dehydration unit at the Farashband refinery using Aspen Plus. represents a significant step towards optimizing the efficiency and reliability […]

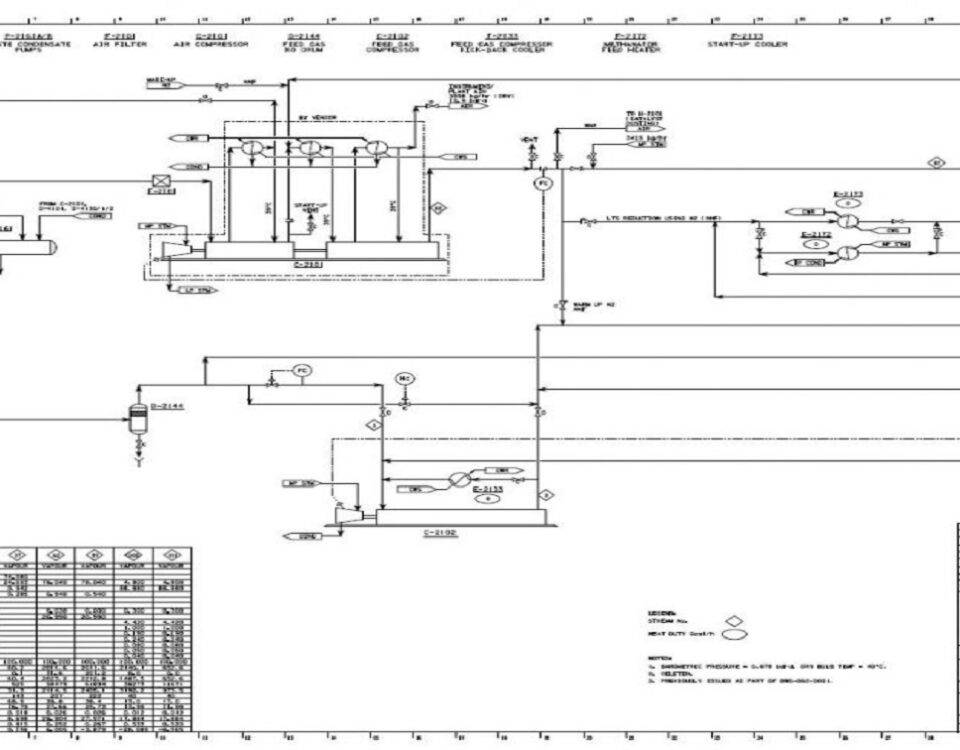

- Introduction The primary feedstocks for ammonia production units are sweet gas (methane) and atmospheric nitrogen. Methane, when mixed with steam and reacted in a primary reformer, […]

- Introduction The transportation of sour gas from offshore platforms to onshore refineries is consistently challenged by various issues, such as hydrate formation and corrosion, which can […]

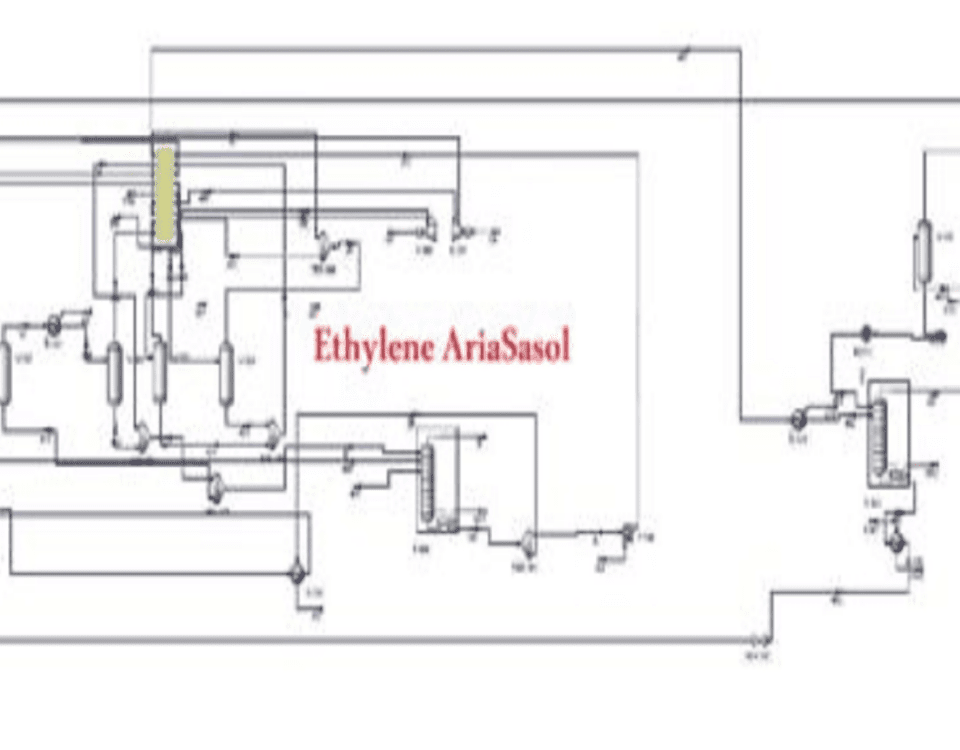

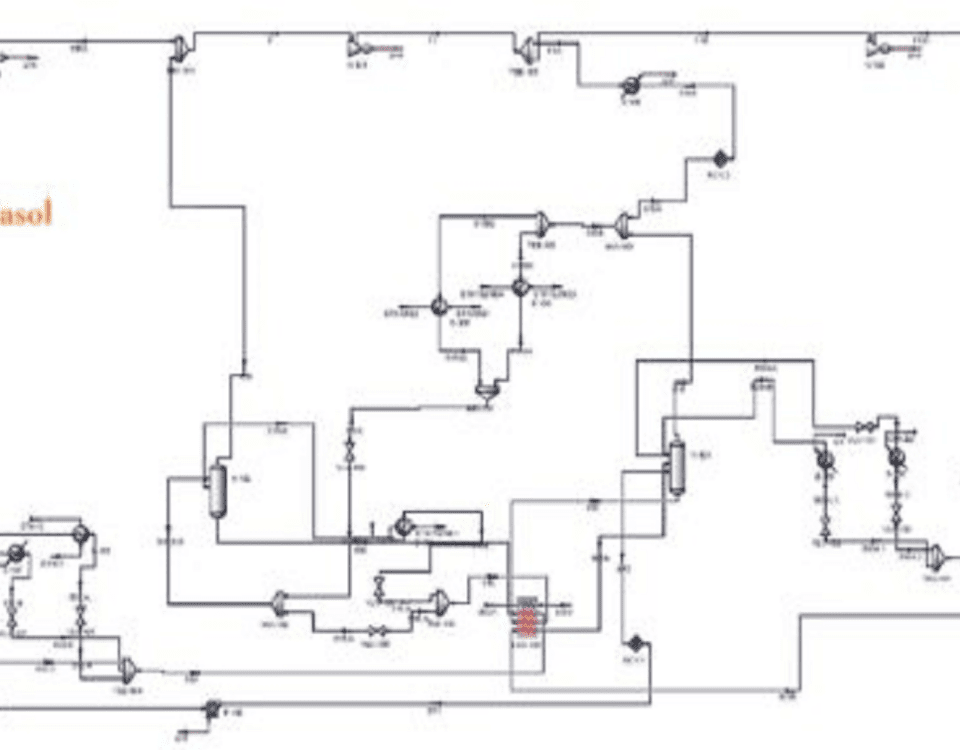

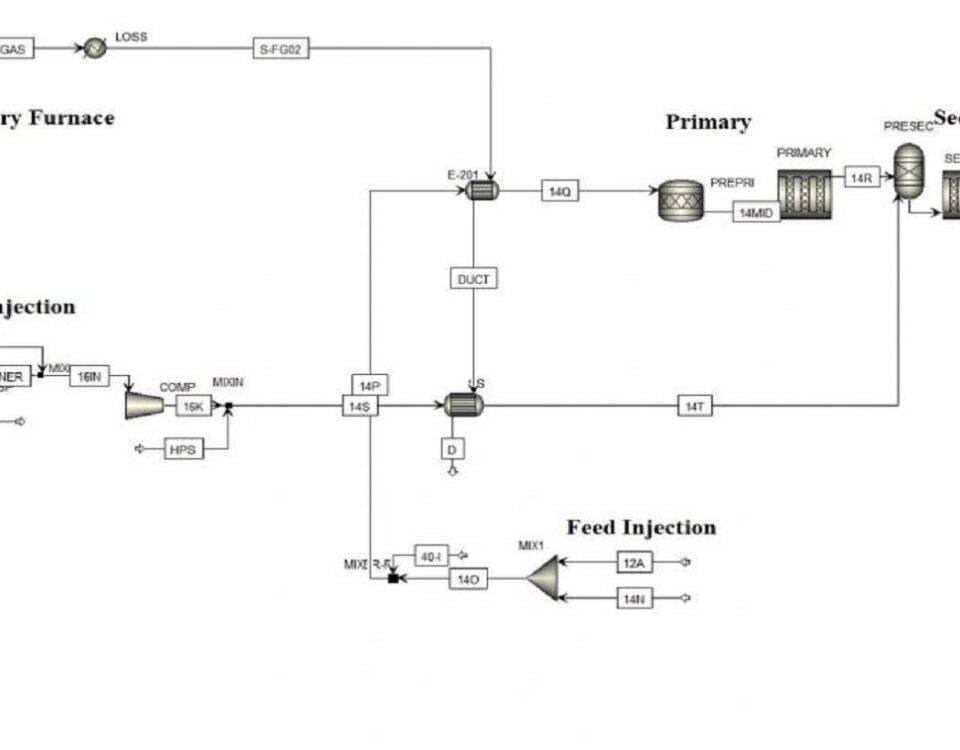

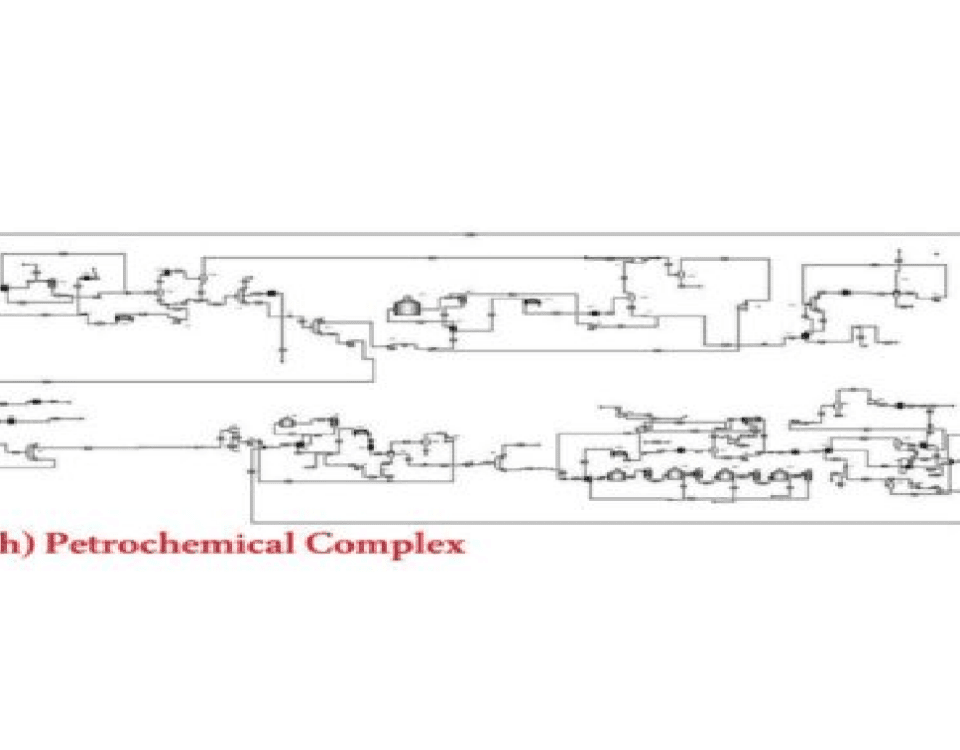

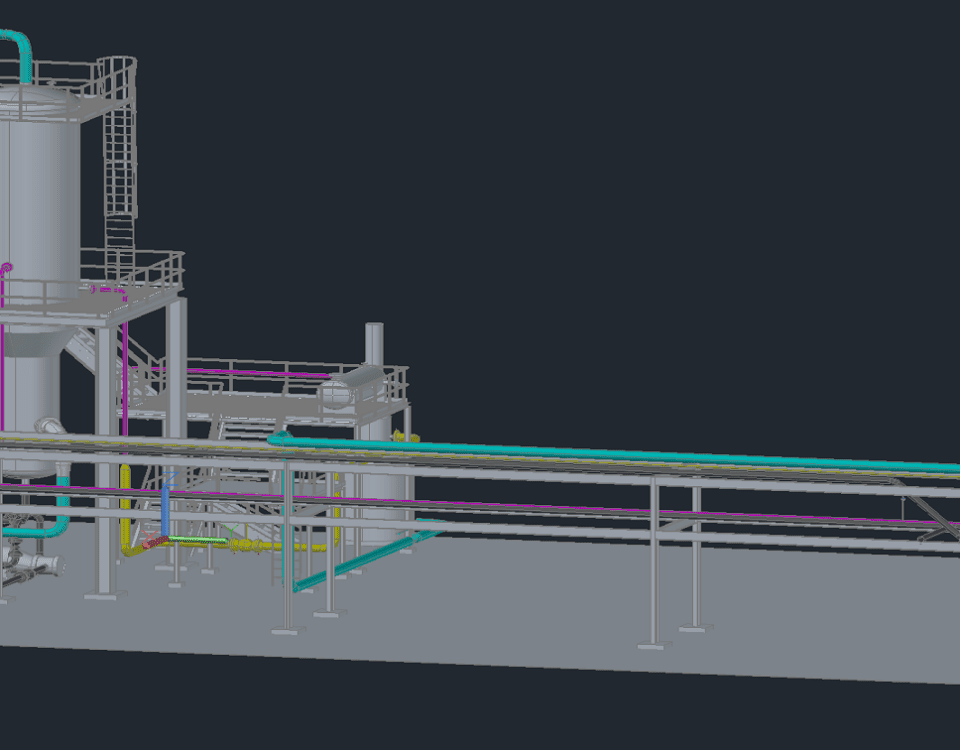

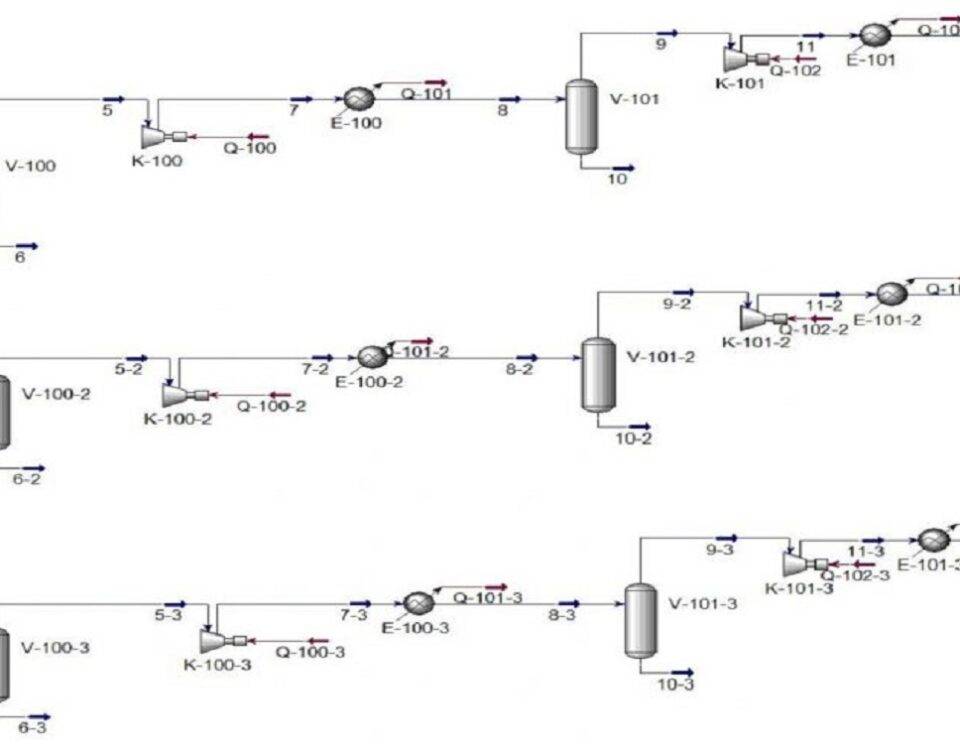

- Description Morvarid Pet. Co. Company is one of the largest ethylene producers in Iran, playing a significant role in the country’s petrochemical industry. This public limited […]

- Introduction Morvarid Petrochemical Company, located in the South Pars Special Economic Zone, is a strategic petrochemical complex in Iran, leveraging advanced technologies and direct access to […]

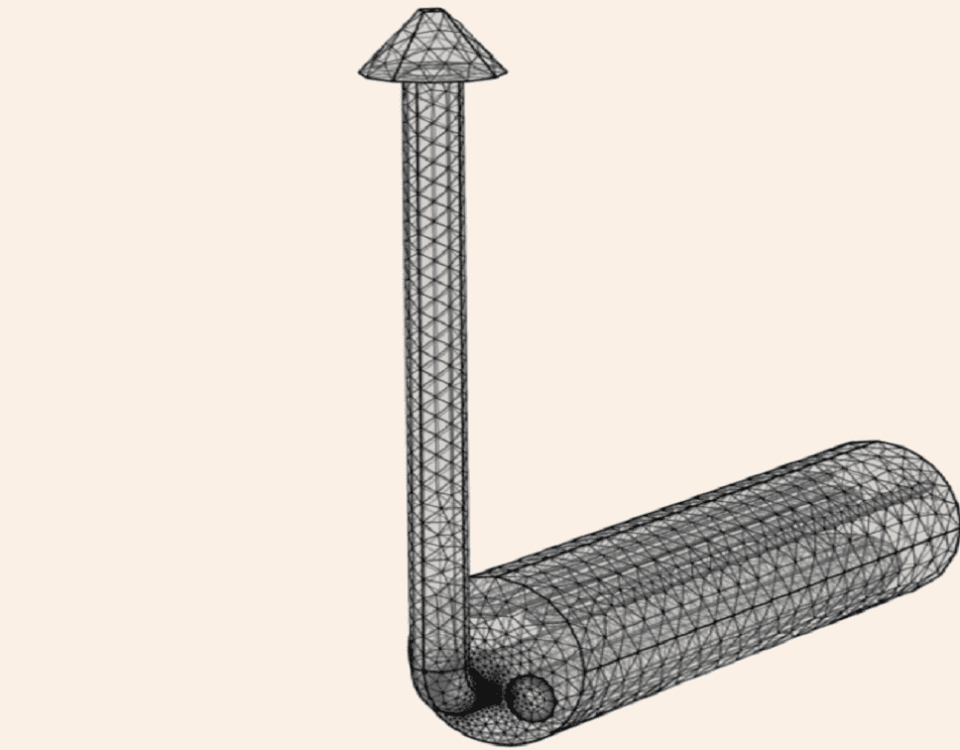

- Introduction A heat exchanger is an essential component in industrial and energy systems, designed to facilitate heat transfer between two or more fluids. Modeling and optimizing […]

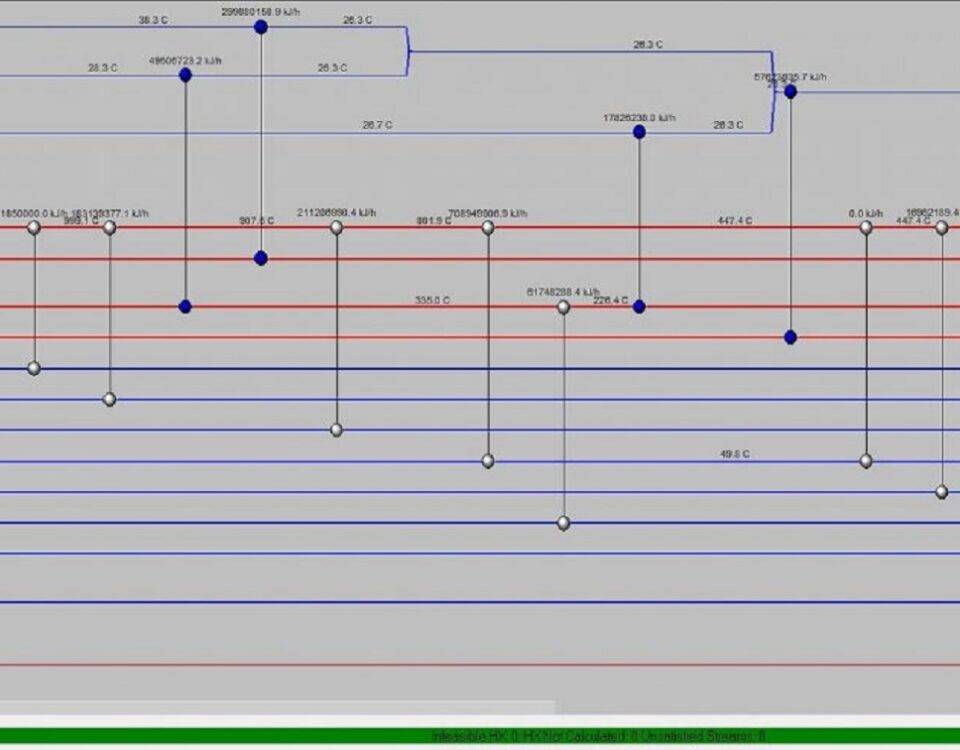

- Introduction Heat Exchanger Network (HEN) design is a crucial aspect of chemical process design. It typically enables energy savings of 20-30% and reduces initial capital costs. […]

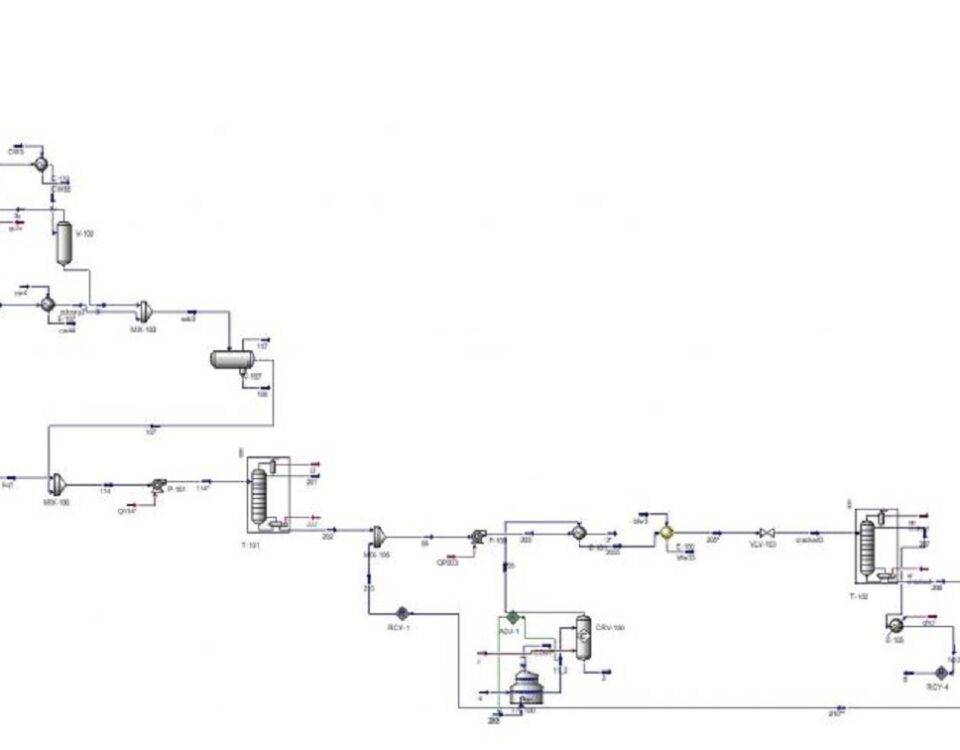

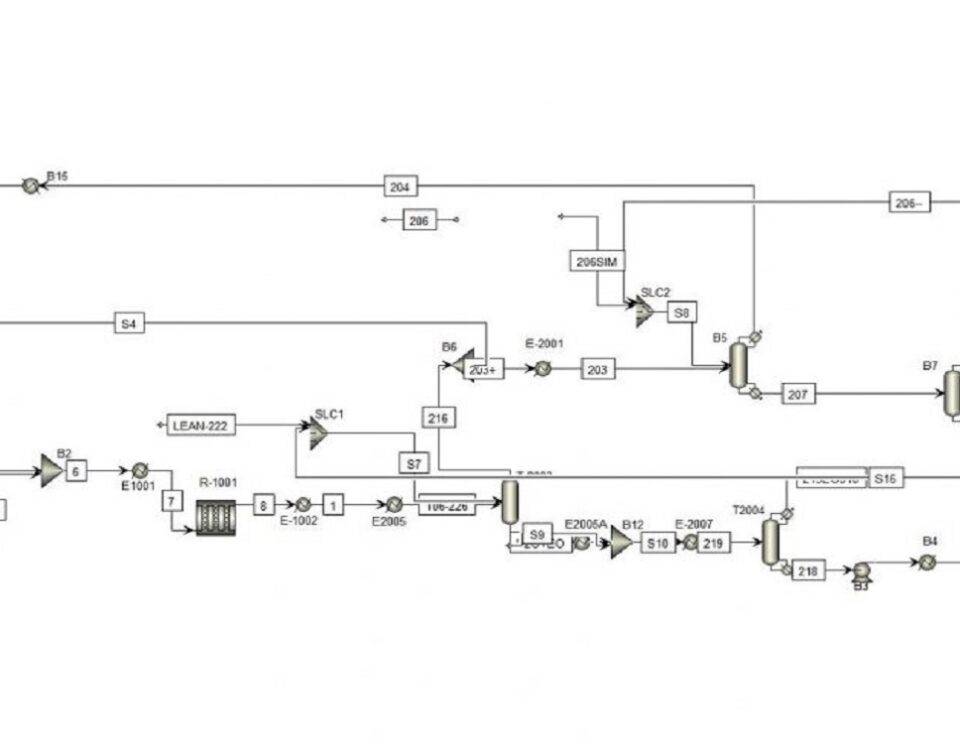

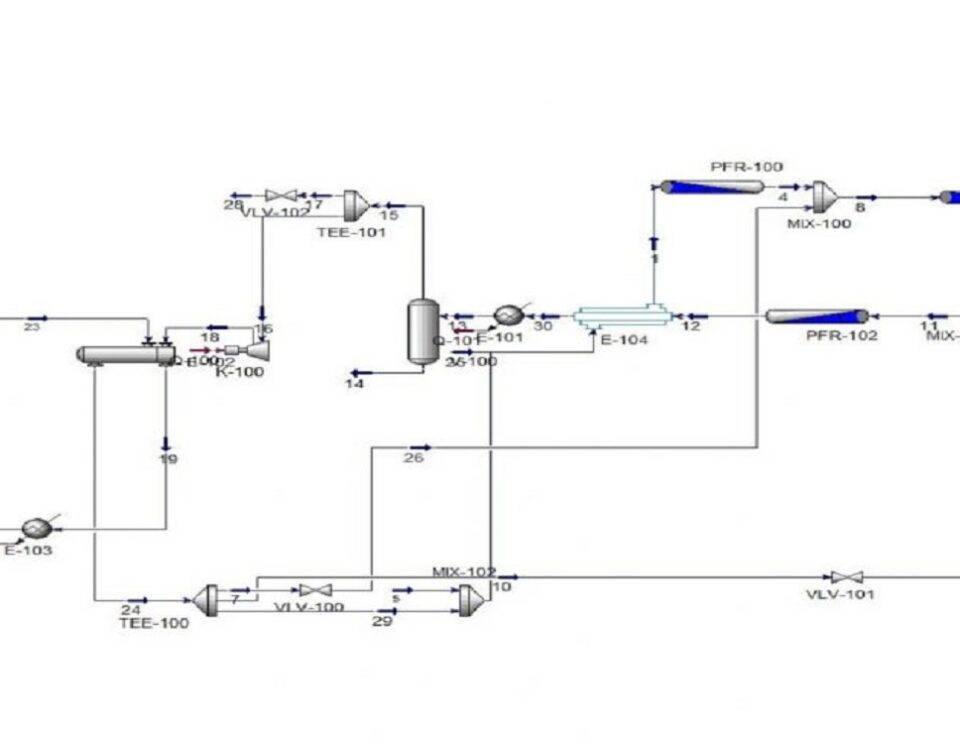

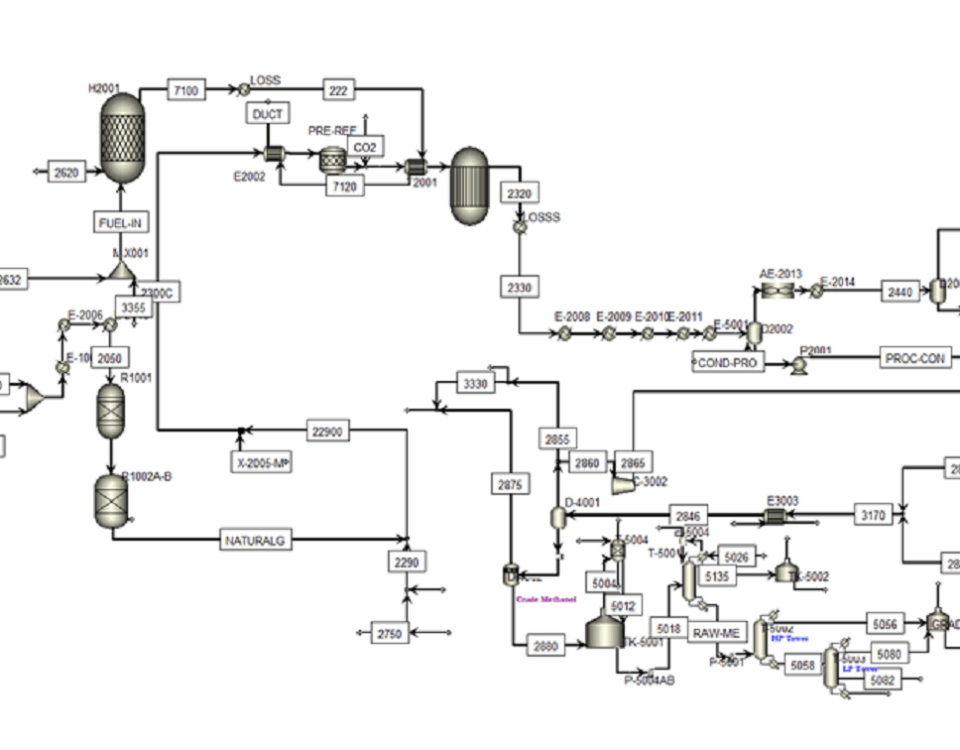

- Introduction This project involved simulating the process units 100 to 700 of the Nouri Petrochemical Complex, a key and intricate industrial project. These units were modeled […]

- Description The design of the Kermanshah Petrochemical Ammonia Unit is based on reducing the energy of the ammonia process, under the technical knowledge (license) of Kellogg […]

- Introduction Ethylene oxide, also known as oxirane, is an organic compound with the formula C₂H₄O. This colorless, flammable gas has a faintly sweet odor and is […]

- Introduction The primary feedstocks for ammonia production units are sweet gas (methane) and atmospheric nitrogen. Methane, when mixed with steam and reacted in a primary reformer, […]

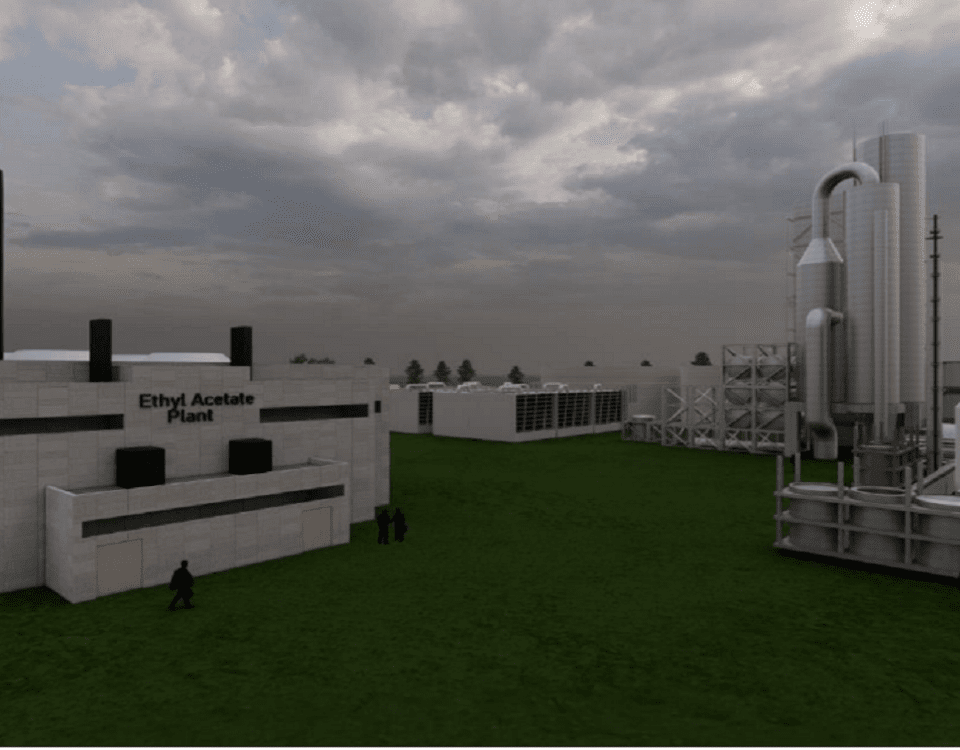

- Introduction The purpose of this project is to build a chemical plant that produces ethyl acetate which will be used as a solvent in synthetic fragrance […]

Design and Engineering of a 100,000 TPD Acetic Acid Ester Production Unit with Reactive Distillation

Design and Engineering of a 100,000 TPD Acetic Acid Ester Production Unit with Reactive Distillation

Introduction The reactive distillation unit for acetic acid esters plays a vital role in the chemical industry, significantly contributing to the production of high-value products. This […]- Description Gas processing Refinery are established to purify and convert gaseous hydrocarbons into various products. Gases produced in gas fields (rich or lean) and associated gases […]

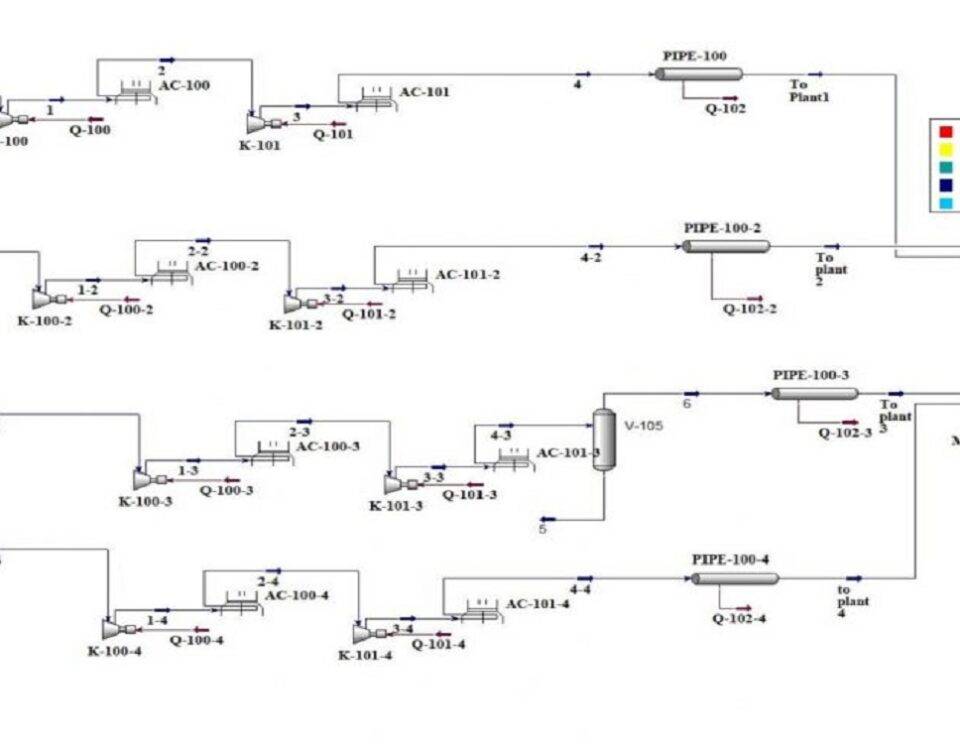

- Introduction A gas refinery is a processing unit designed to process, prepare, and optimize the properties of natural gas extracted from gas wells. In a gas […]

- Description The oil and gas refining industry is considered as one of the major consumers of energy and a lot of money is spent on energy […]

- Description An ammonia production unit is a crucial facility within the chemical industry, dedicated to producing ammonia (NH₃), a highly important and widely used chemical compound. […]

- Description The gas sweetening refinery is one of the facilities of the Amak oil gas collection project. which sweetens sour gasses with oil in Timur, Maron, […]

- Introduction Natural gas dehydration is the process of removing water that exists in the form of vapor alongside natural gas. It has been established in the […]

- Introduction In the fast-paced world of industry and technology, hydrogen has gained a special place as a clean energy carrier and a raw material for many […]

- Description Natural gas extracted from gas reservoirs mainly contains a significant amount of gas condensate. Especially when the volume of gas withdrawal from the tank is […]