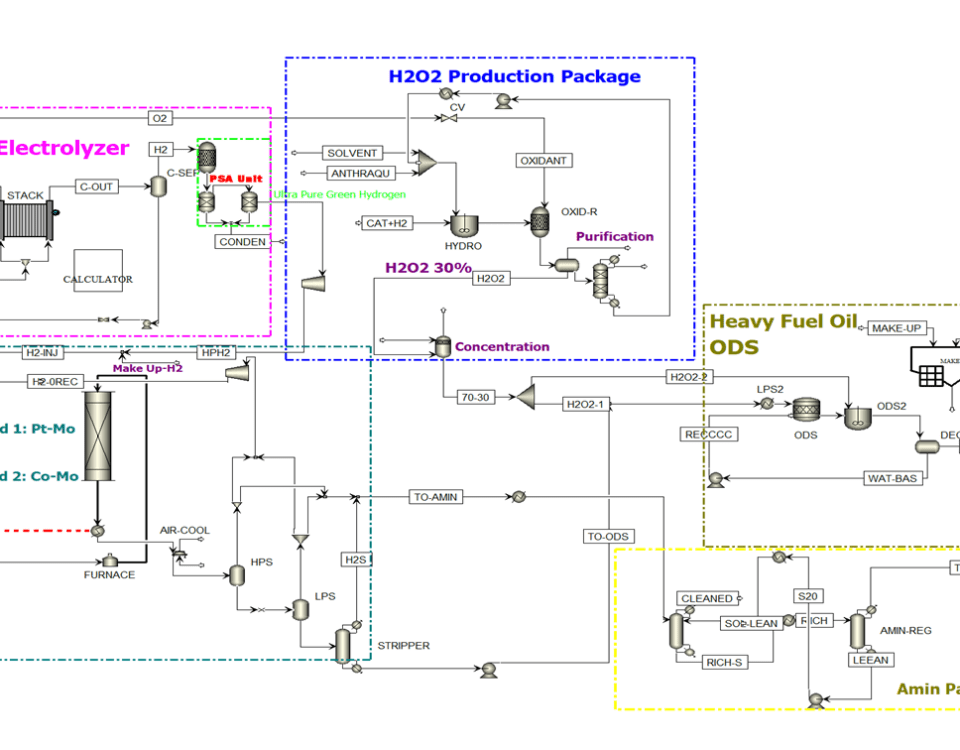

- Introduction The oil refining industry faces numerous challenges in today’s world, including compliance with environmental regulations and improving fuel quality. One of the primary concerns is […]

- The Importance of Fuel Oil Desulfurization Fuel oil is one of the primary products of crude oil refining, widely used as fuel in maritime transportation, power […]

- Introduction The Importance of Energy Optimization in Process Industries Process industries, including oil, gas, and petrochemical sectors, consistently face numerous challenges related to energy consumption. Implementing […]

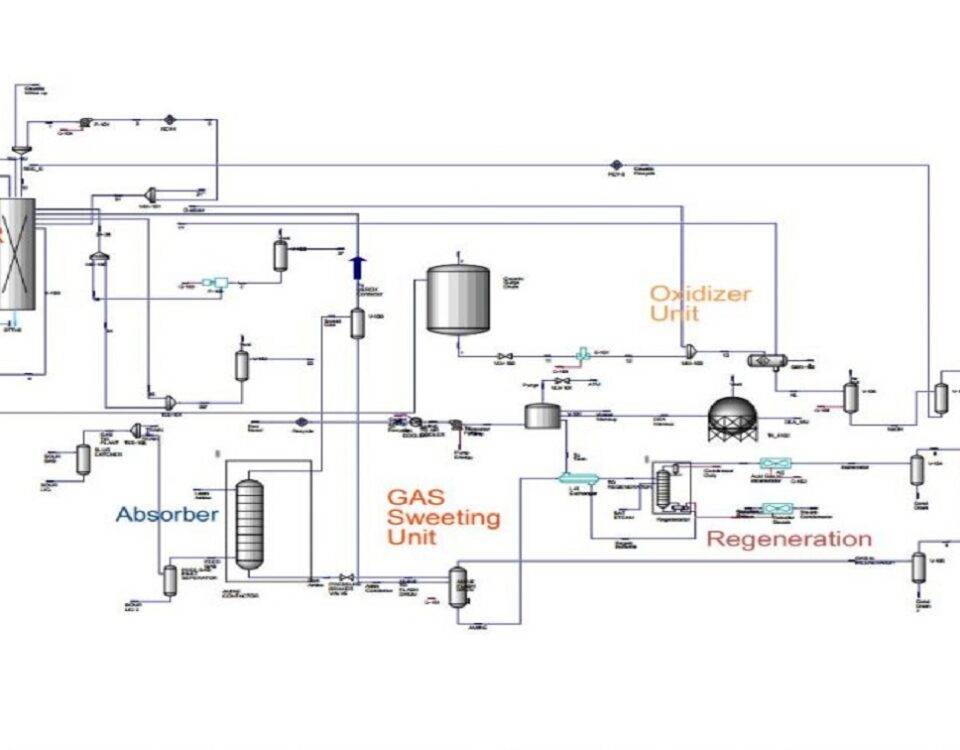

- Introduction Natural gas sweetening is a critical step in the production and refining of hydrocarbon gases. The objective of this process is to remove undesirable compounds […]

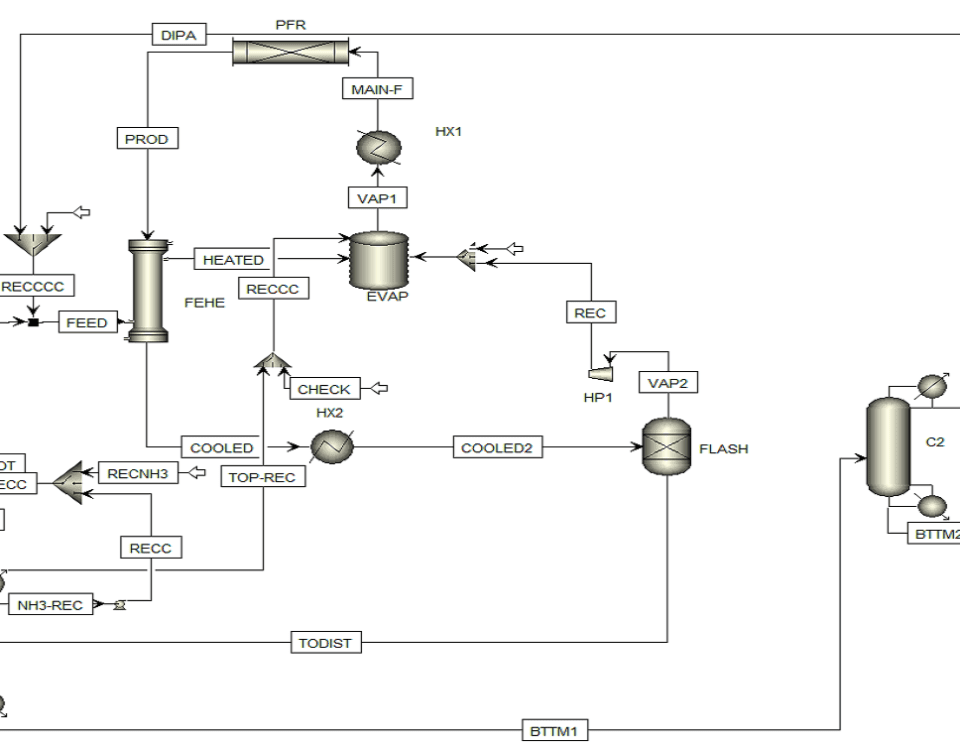

- Introduction Nitric acid (HNO₃) is one of the most widely used and important mineral acids in the chemical industry, holding a significant position in industrial processes […]

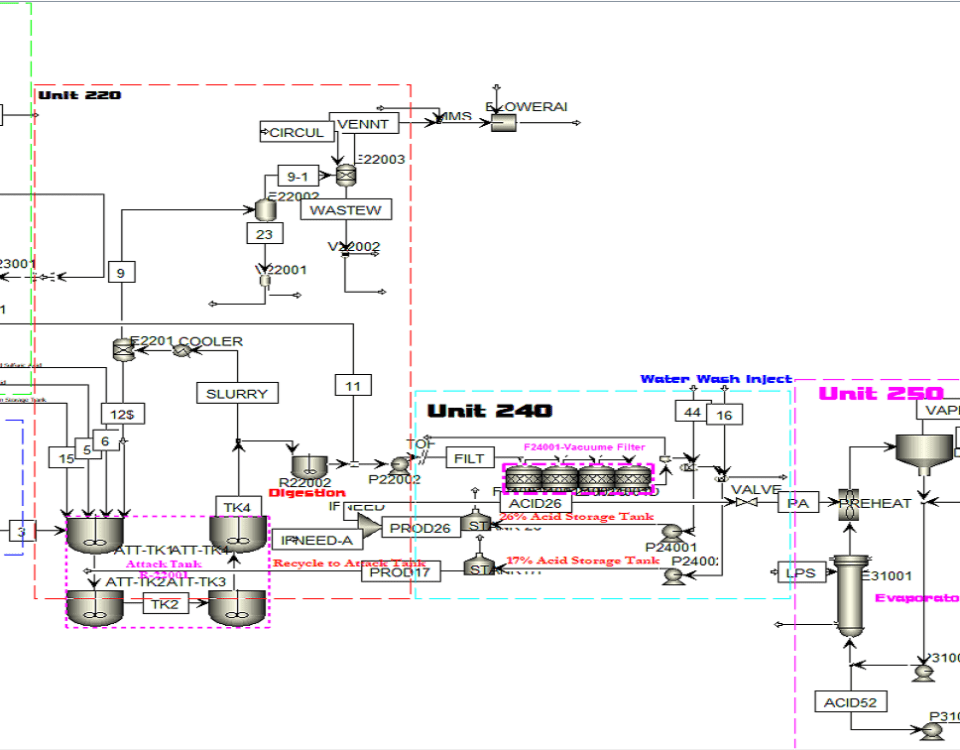

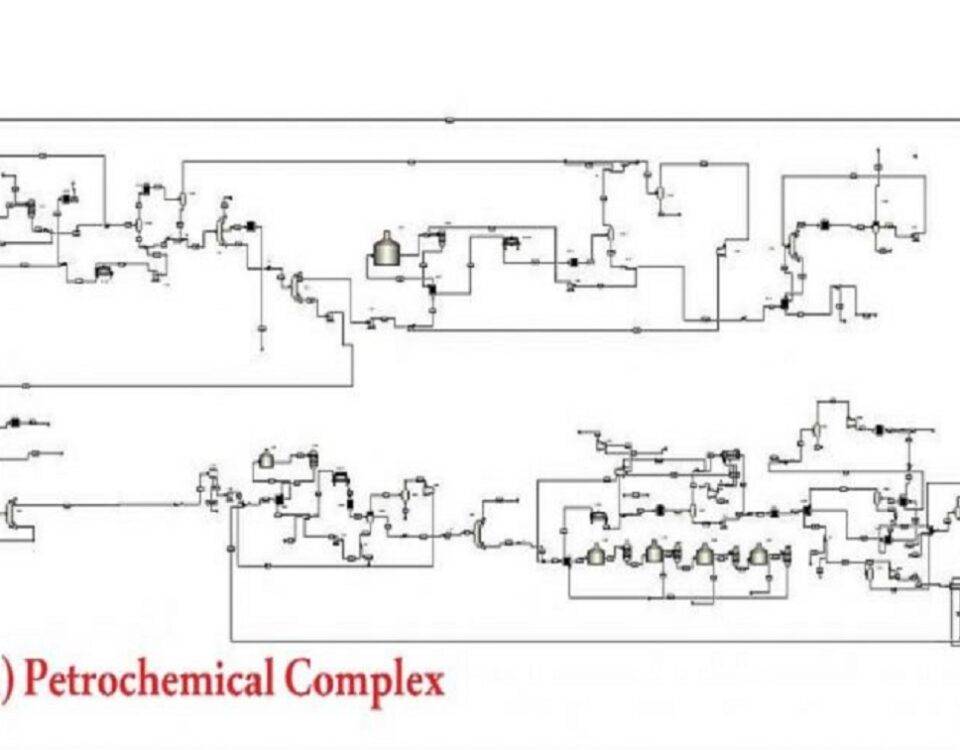

- Introduction Process engineering and simulation of complex chemical processes have always been significant and challenging topics in the chemical and petrochemical industries. The production process of […]

- Introduction Phosphoric acid is considered a strategic material in the basic chemical industries due to its applications in various sectors and the lack of suitable alternatives. […]

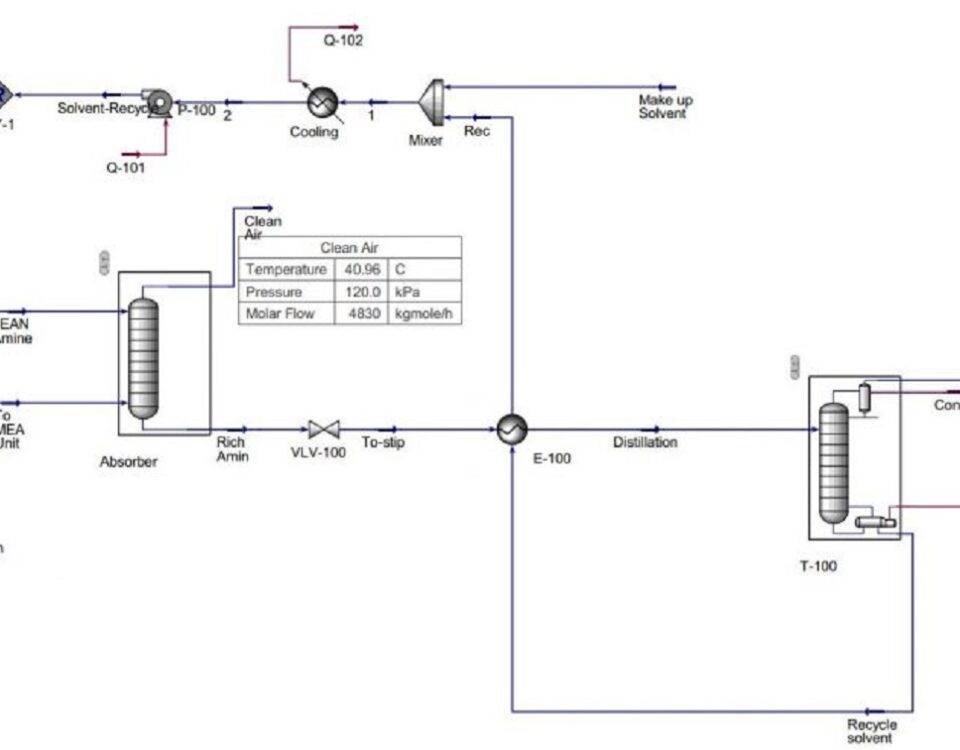

- Introduction After the industrial revolution, the concentration of greenhouse gases in the atmosphere rapidly increased. Global warming is driven by the emission of greenhouse gases, with […]

- Introduction The Sulfur Recovery Unit (Unit 114, South Pars Field Phases 9 and 10) serves as a vital component of petrochemical complexes in Iran, established with […]

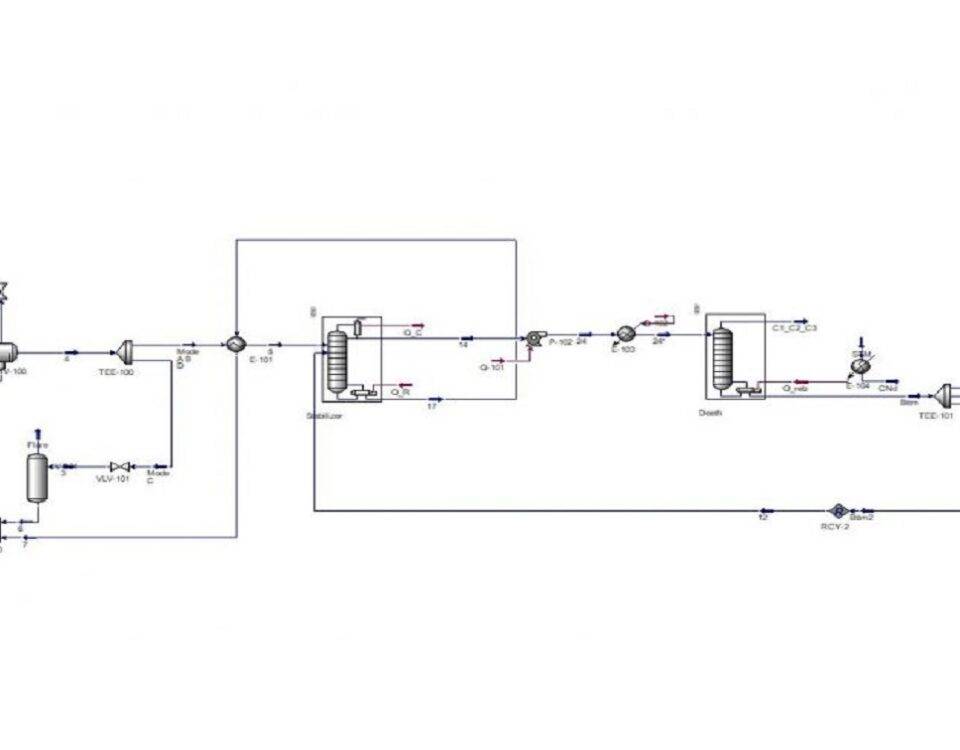

- Description Gas condensate after separation from natural gas contains volatile elements from light hydrocarbons such as methane, ethane, etc. If they are placed in suitable environmental […]

- Introduction Oil refineries are the backbone of modern economies, powering industries, transportation, and households. Without their refined products, the world would grind to a halt. From […]

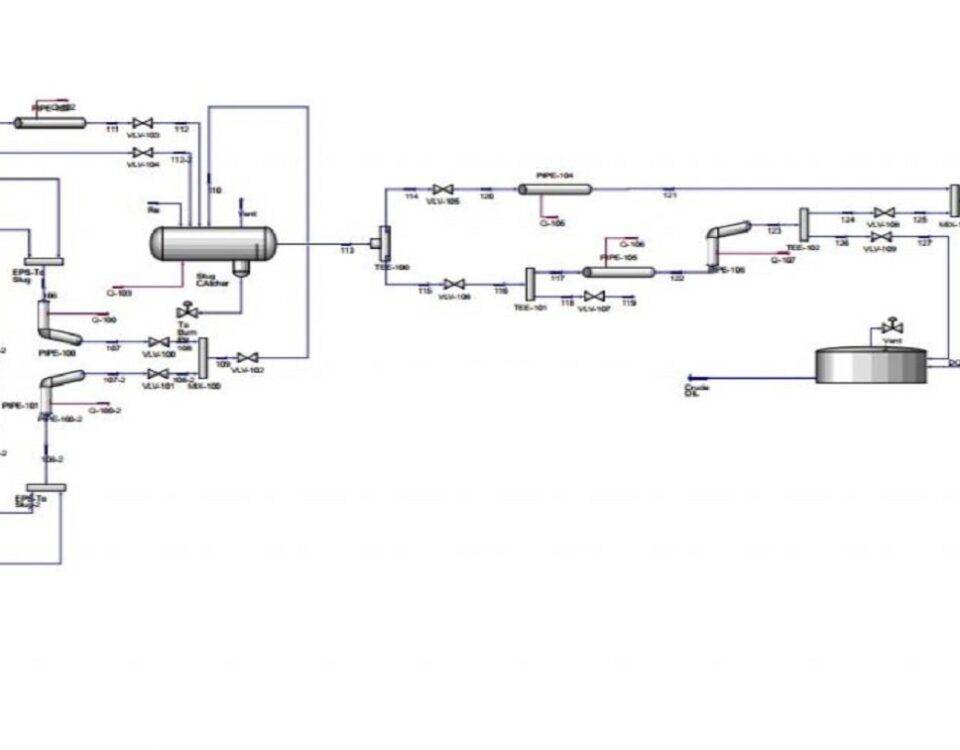

- Description Aspen Hysys simulation of the general process of transferring oil to the amount of 50k barrels per day After the end of the drilling and […]

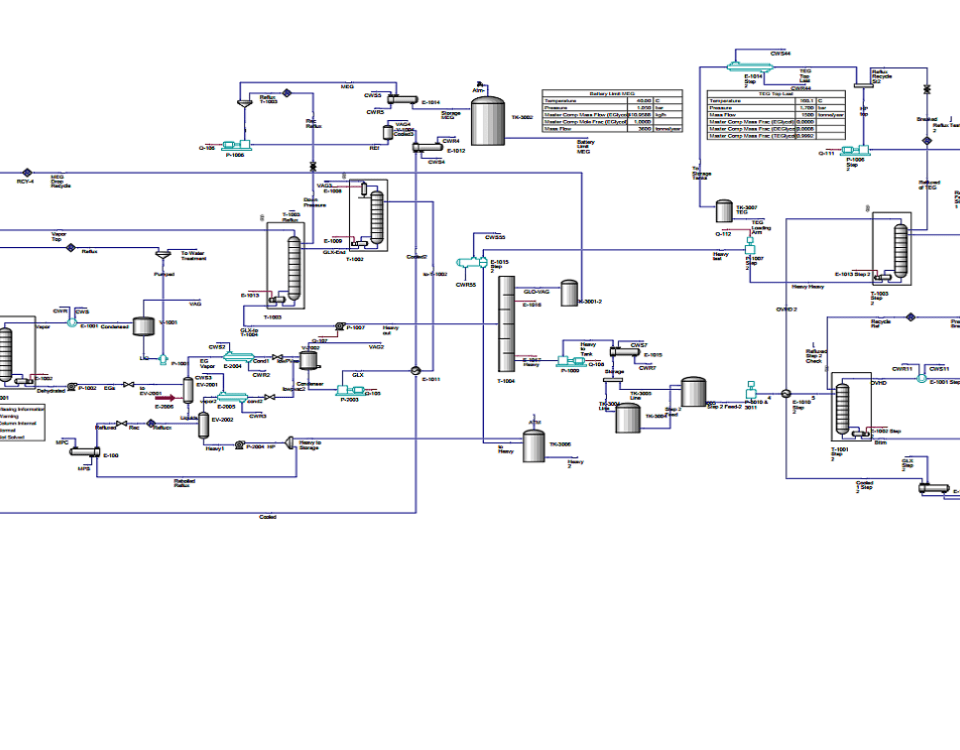

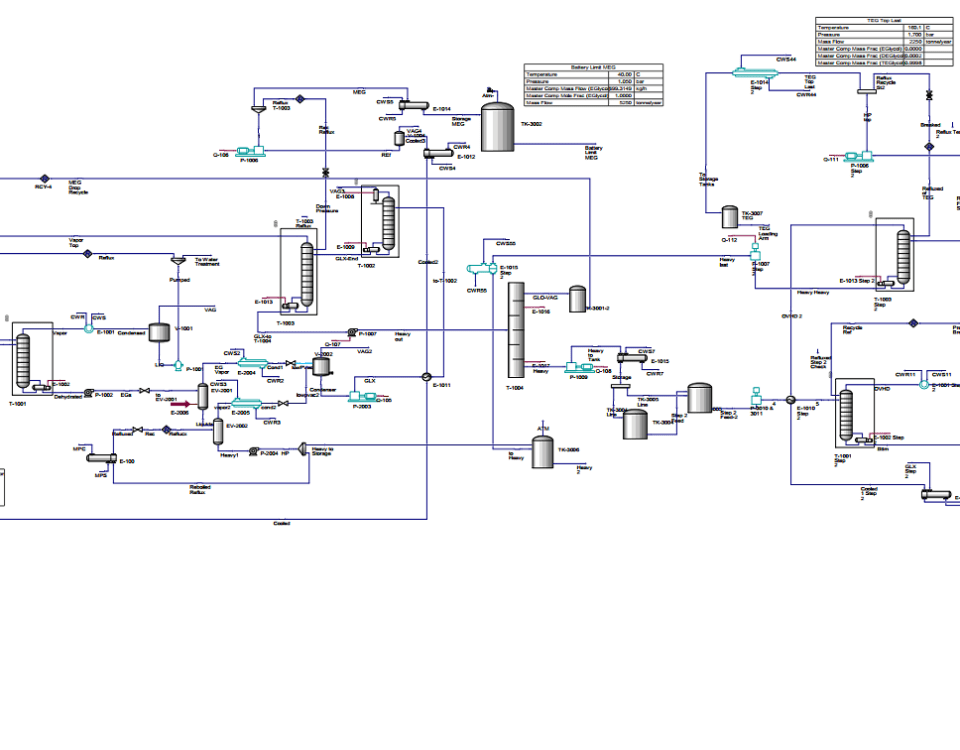

- Introduction This study examines the feasibility of an ethylene glycol separation and purification unit with a capacity of 15 KTY. Two main scenarios are analyzed: the […]

- Introduction This study is particularly beneficial and practical for engineers and technical managers responsible for the commissioning and operation of industrial units. The initial section of […]

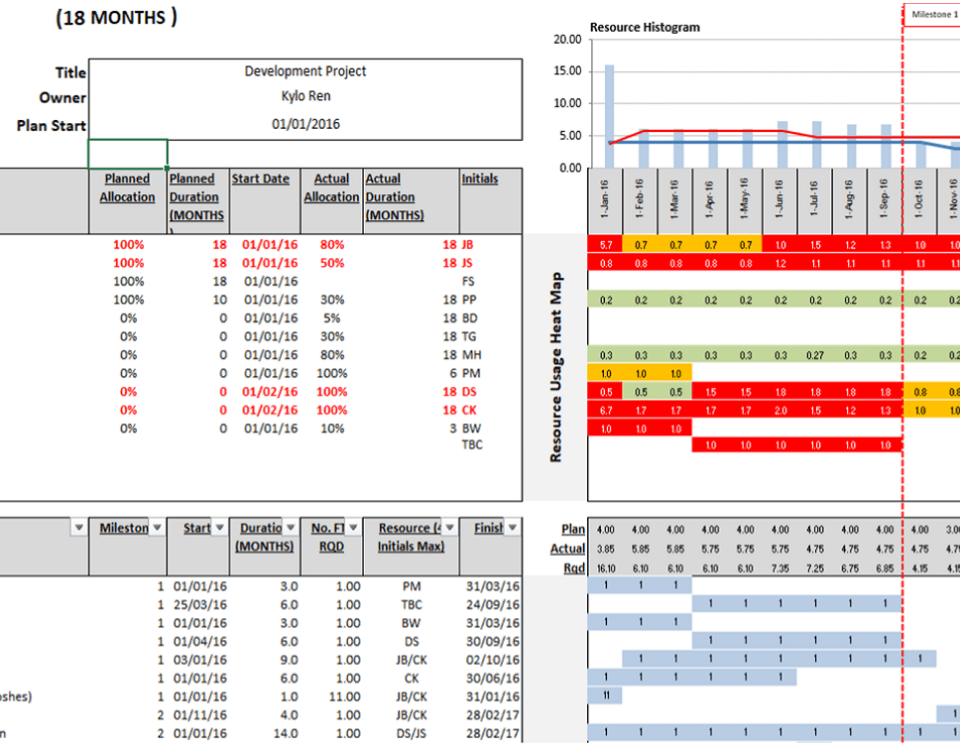

- Introduction The MRP.xlsx file is designed as a key resource for analyzing the performance of the Arta Chemistry manufacturing plant, containing comprehensive and detailed information across […]

- Introduction In the rapidly evolving landscape of the global chemical industry, there is an increasing demand for versatile and essential chemicals, among which Monoethylene Glycol (MEG), […]

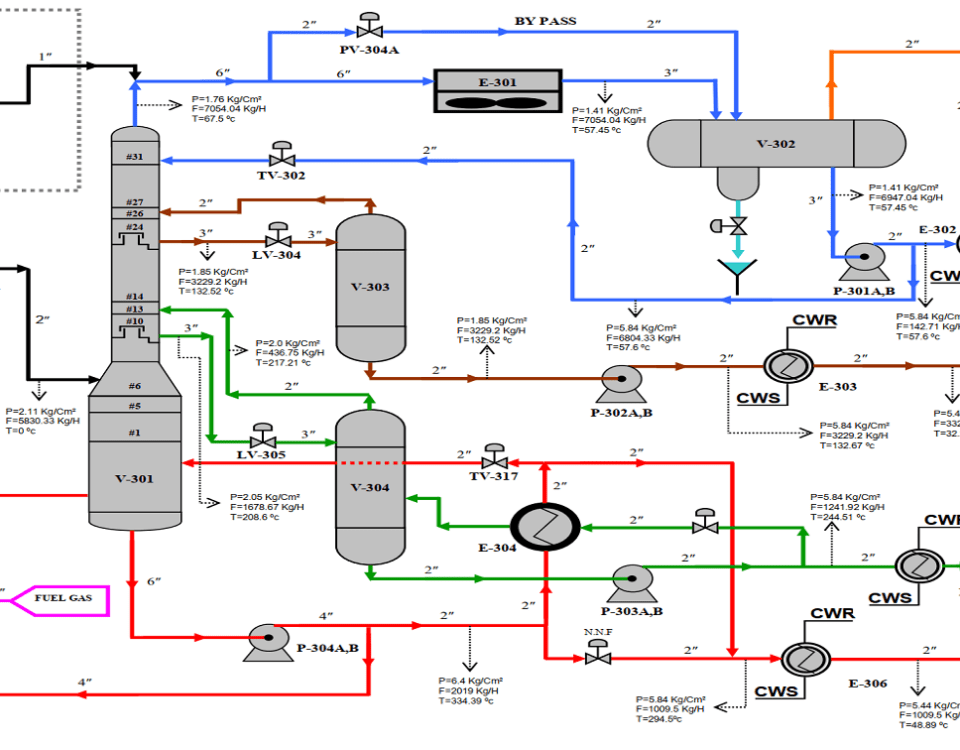

- Description Merox process: In this process, the gas is washed with caustic soda and water in (3) steps. It consists of three parts. It contains 33 […]

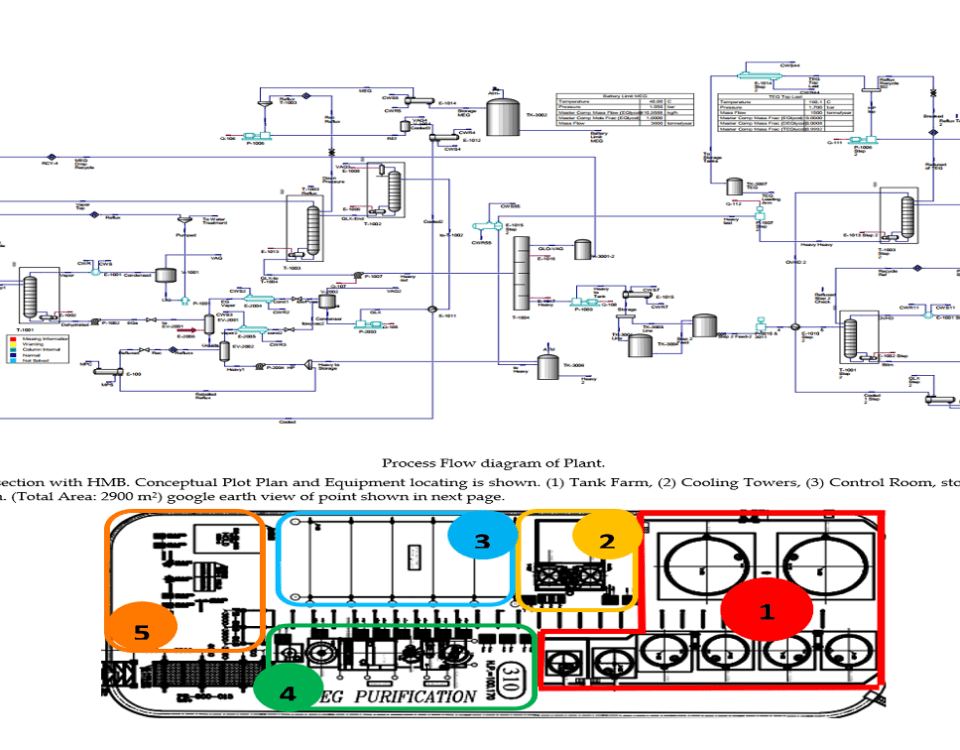

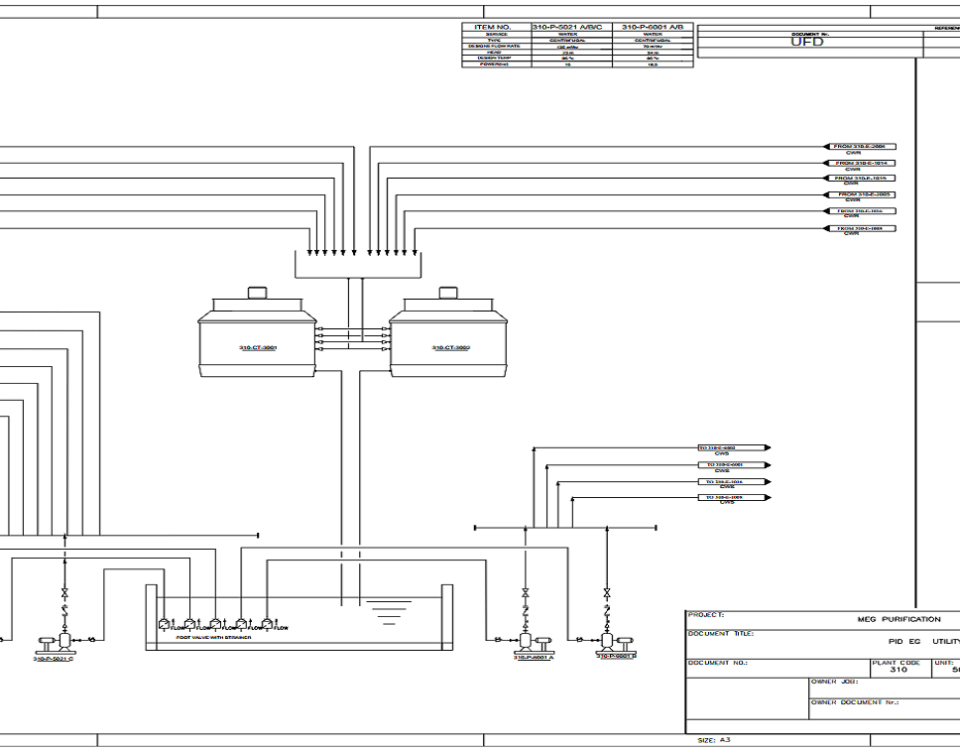

- Introduction The design of engineering documents and diagrams related to the Ethylene Glycol Purification Unit holds significant importance in industrial processes, as these documents lay the […]

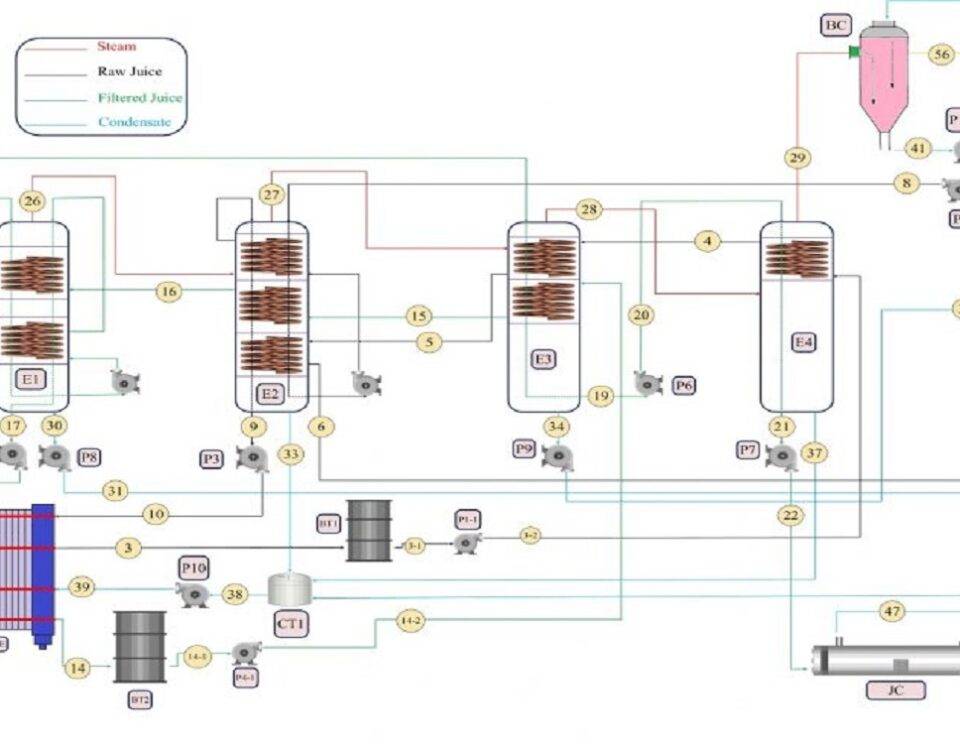

- Introduction The fruit concentrate production line in this company consists of four stages of falling film evaporator, the energy needed for the first stage is provided […]

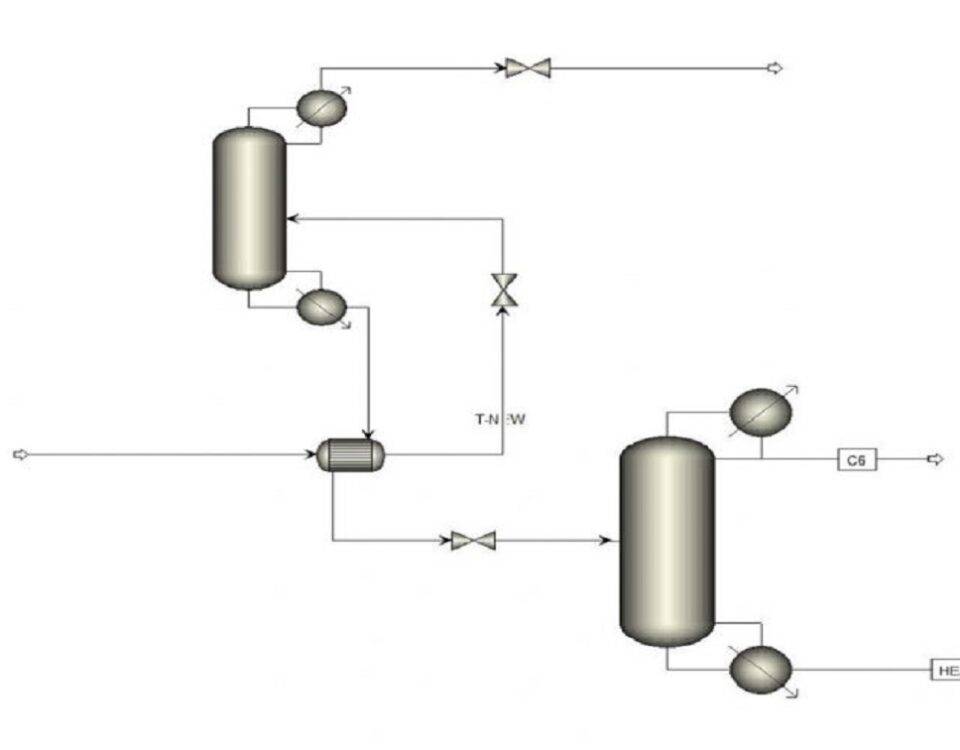

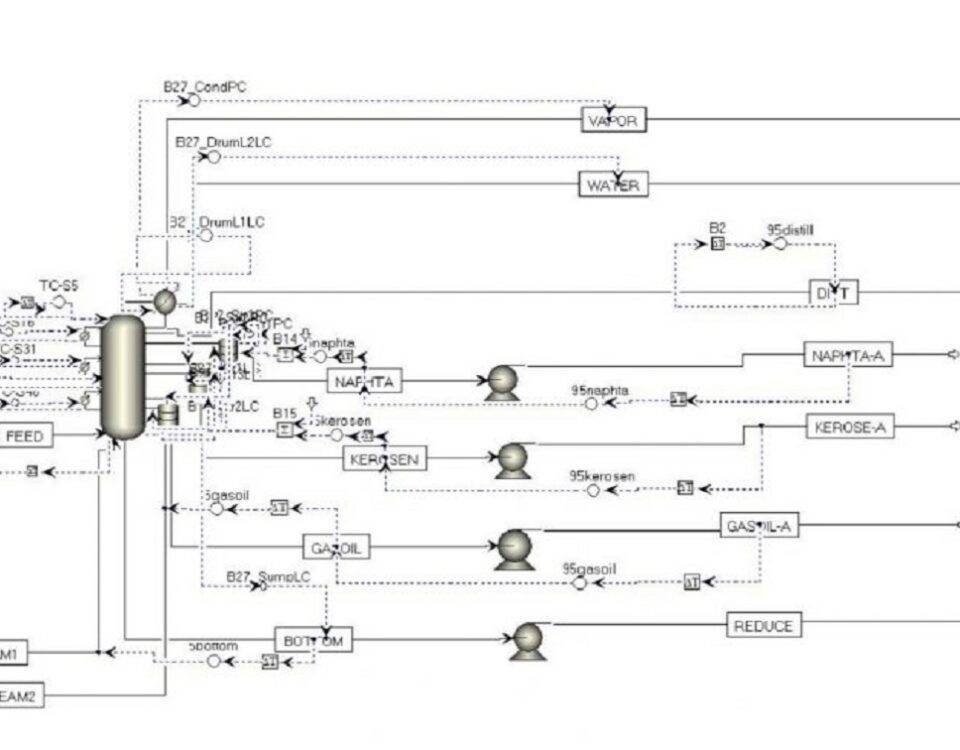

- Introduction The simulation of the T-2501 tower at the Borzouyeh Petrochemical Company using Aspen Plus is a key step in the analysis and optimization of chemical […]

- Introduction The purification process of Monoethylene Glycol (MEG) has gained increasing importance in various industries, particularly in the production of polyester fibers and polyethylene terephthalate resins. […]

- Introduction The simulation and optimization of the Monoethylene Glycol (MEG) purification process with a production capacity of 15 KTY play a crucial role in enhancing operational […]

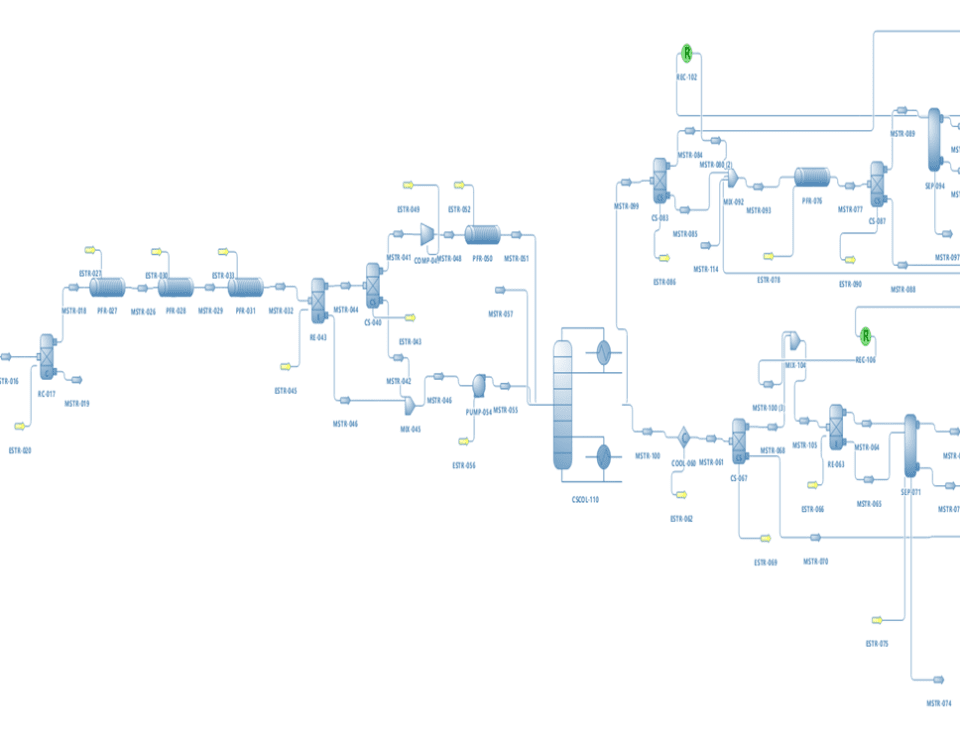

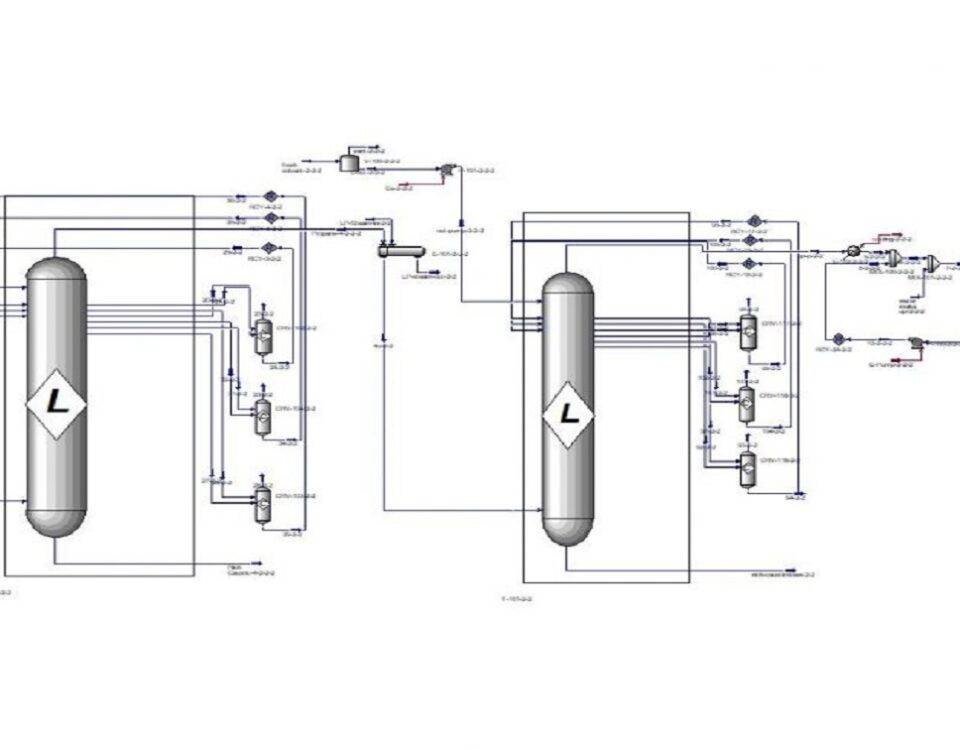

- Description In this project, 100 to 700 NOURI (Borzooyeh) Petrochemical units are simulated using industrial PFDs by Aspen Plus version 10 software. The process units of […]

- Introduction Petroleum refining is essentially a series of physical and chemical changes applied to the input product of a refinery, which is crude oil, and its […]