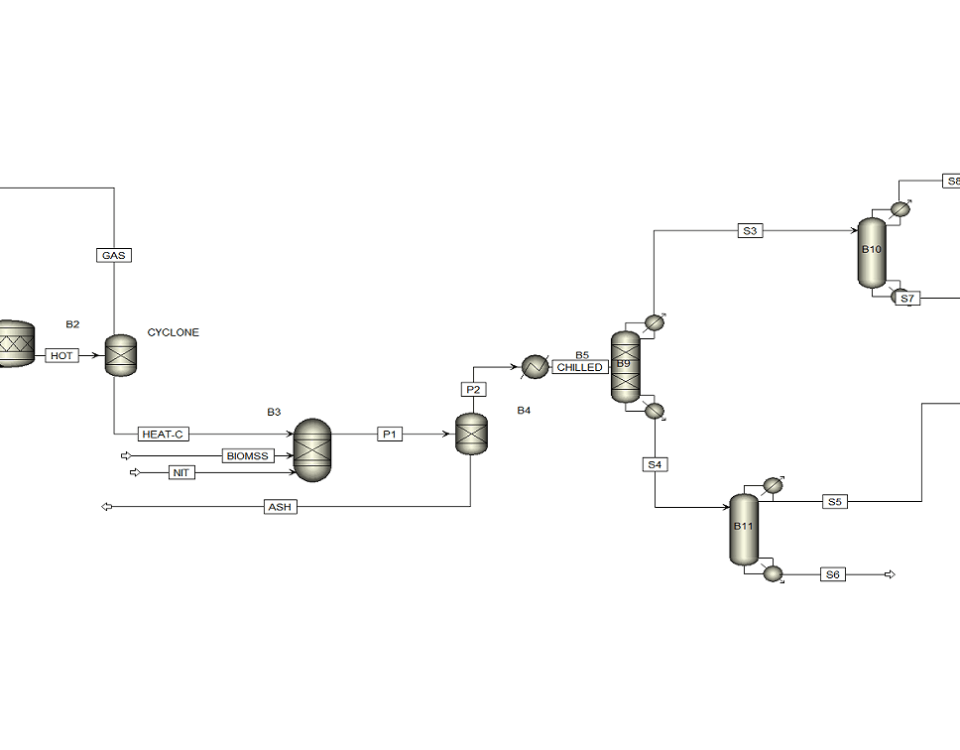

- Introduction Bagasse, a fibrous byproduct of sugarcane processing, is derived from the residue left after sugarcane stalks are crushed to extract juice. This lignocellulosic material has […]

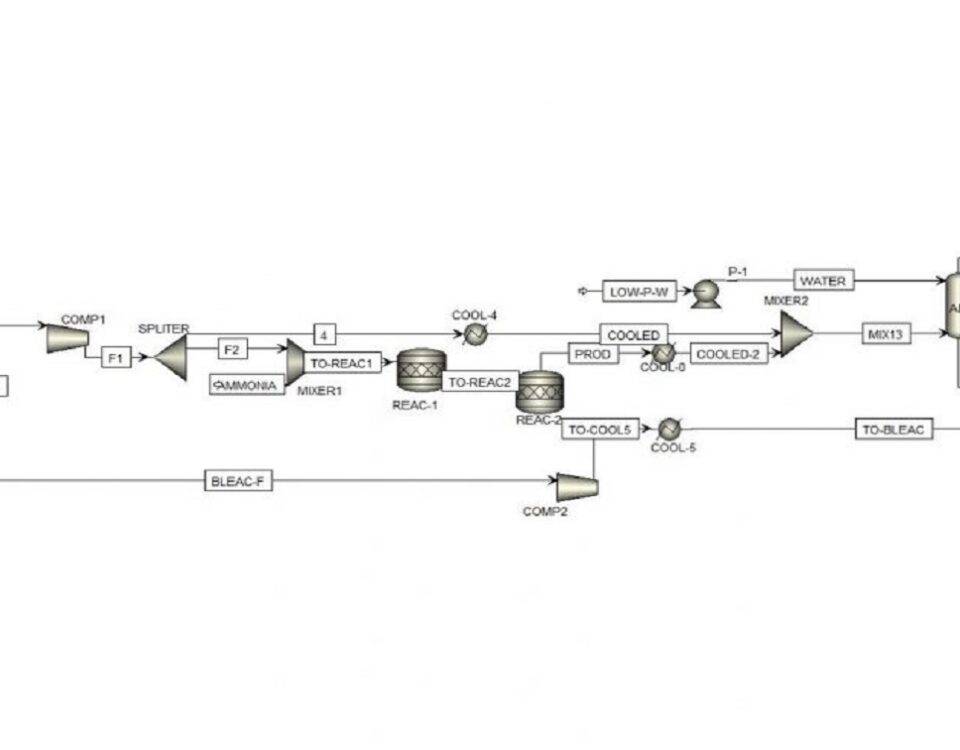

- Introduction Nitric acid is a strong acid with high oxidizing properties. When heated at atmospheric pressure, it boils at 78.2°C and begins to decompose, eventually forming […]

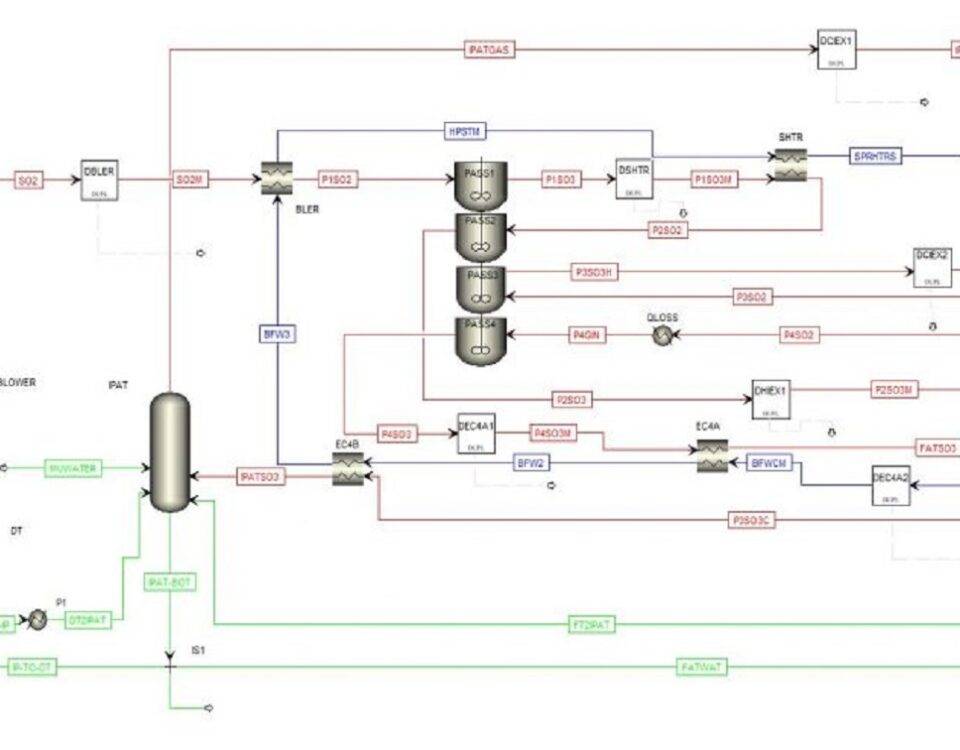

- Introduction Sulfuric acid, as one of the most important and widely used chemicals in the industry, plays a key role in various production processes. This compound […]

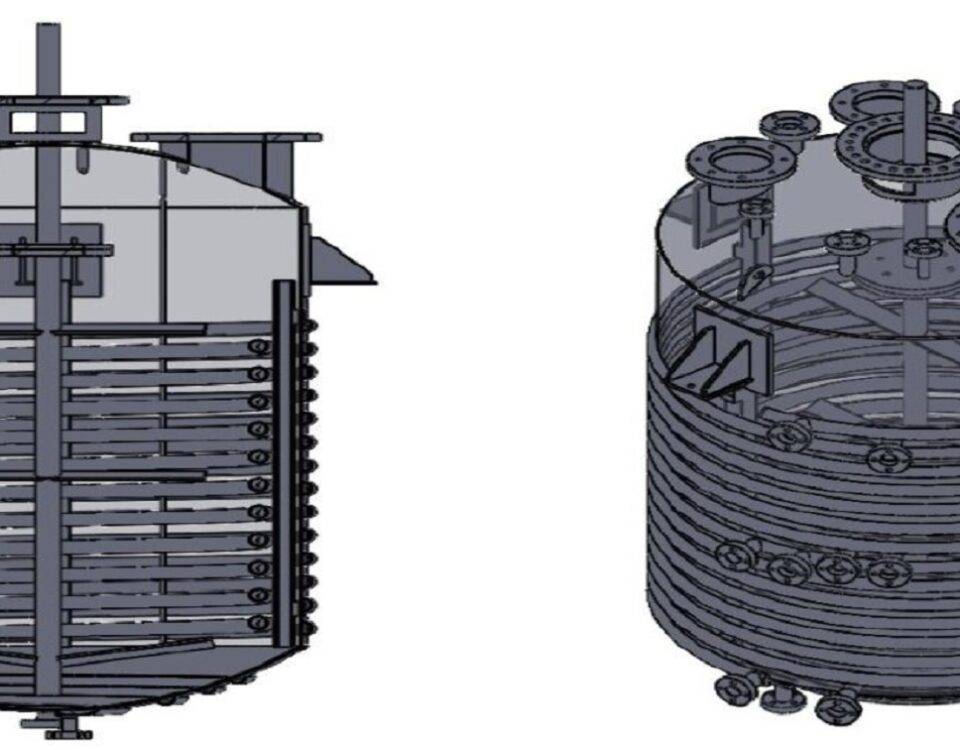

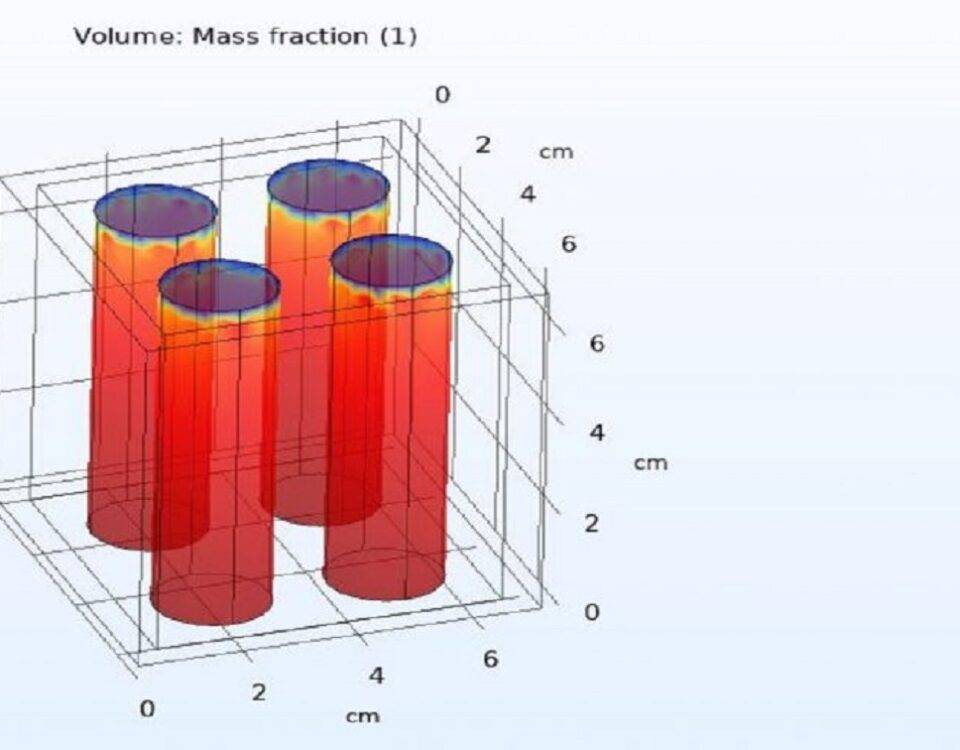

- Introduction 3D design of reactors as one of the key steps in chemical engineering. And industrial processes provide the possibility of realizing precise and optimal designs. […]

- Introduction Isopropyl alcohol is a colorless, flammable liquid with a pungent odor. It is widely used as a solvent and disinfectant, particularly for dissolving oils. Isopropanol […]

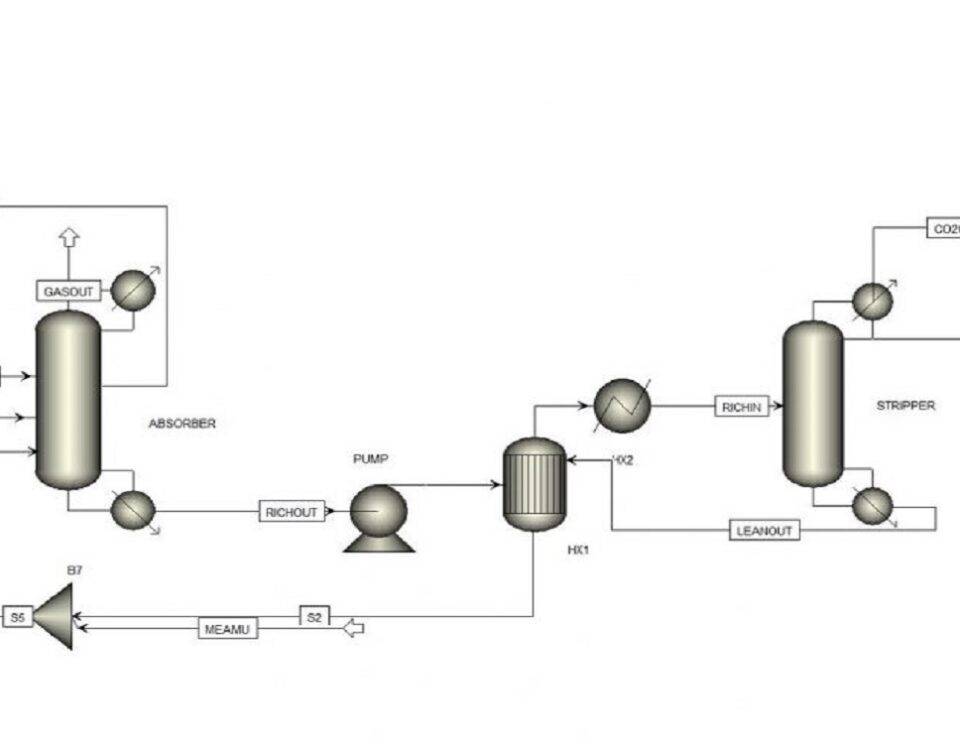

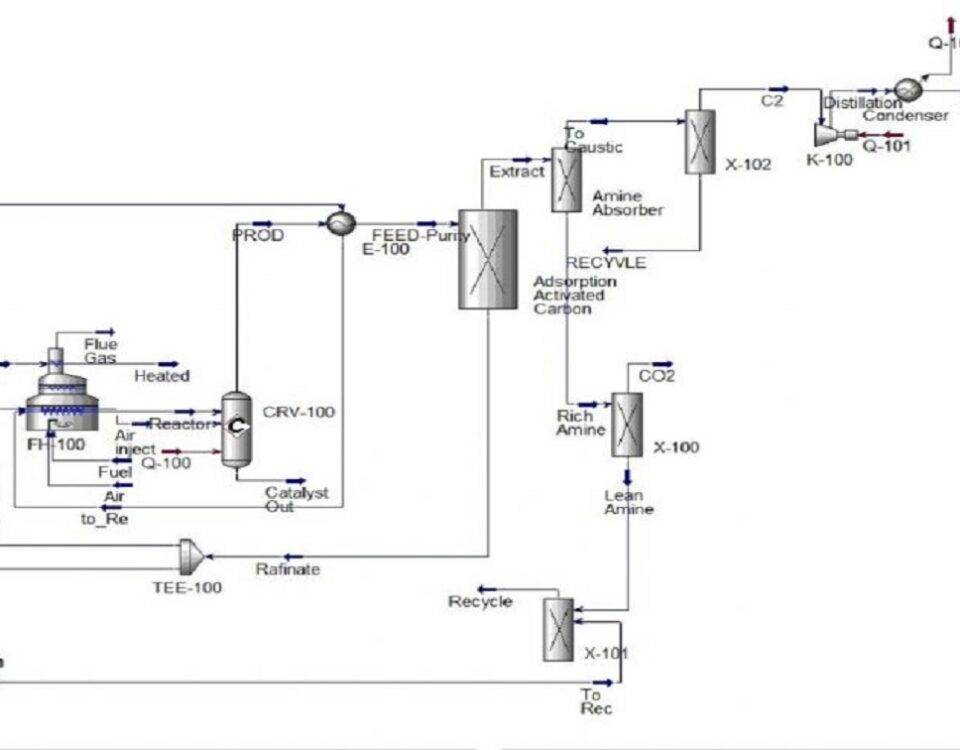

- Introduction Most CO2 separation processes rely on physical or chemical absorption of this substance in a suitable solvent. In physical absorption, the efficiency of the process […]

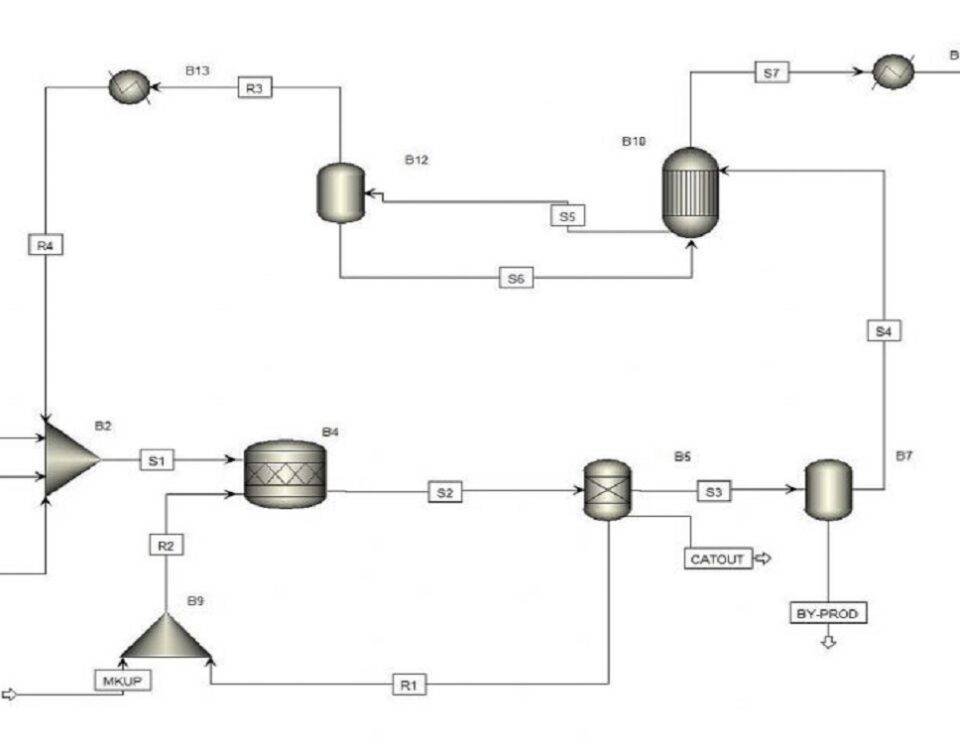

- Introduction The primary feedstocks for ammonia production units are sweet gases (methane) and atmospheric nitrogen. Methane gas, after being mixed with steam and undergoing a reaction […]

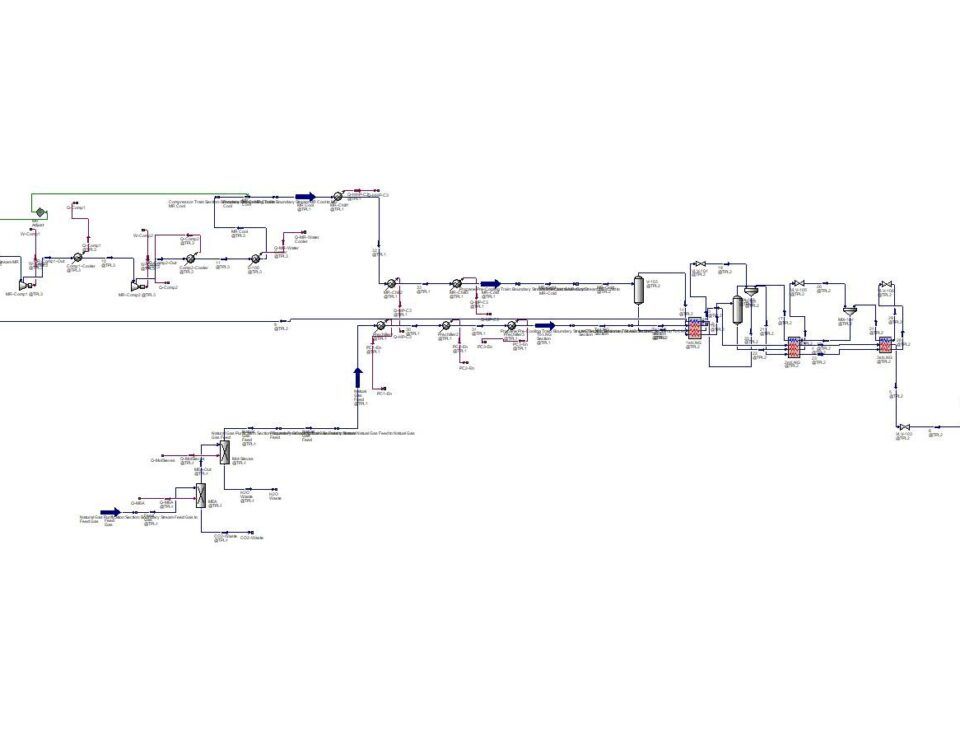

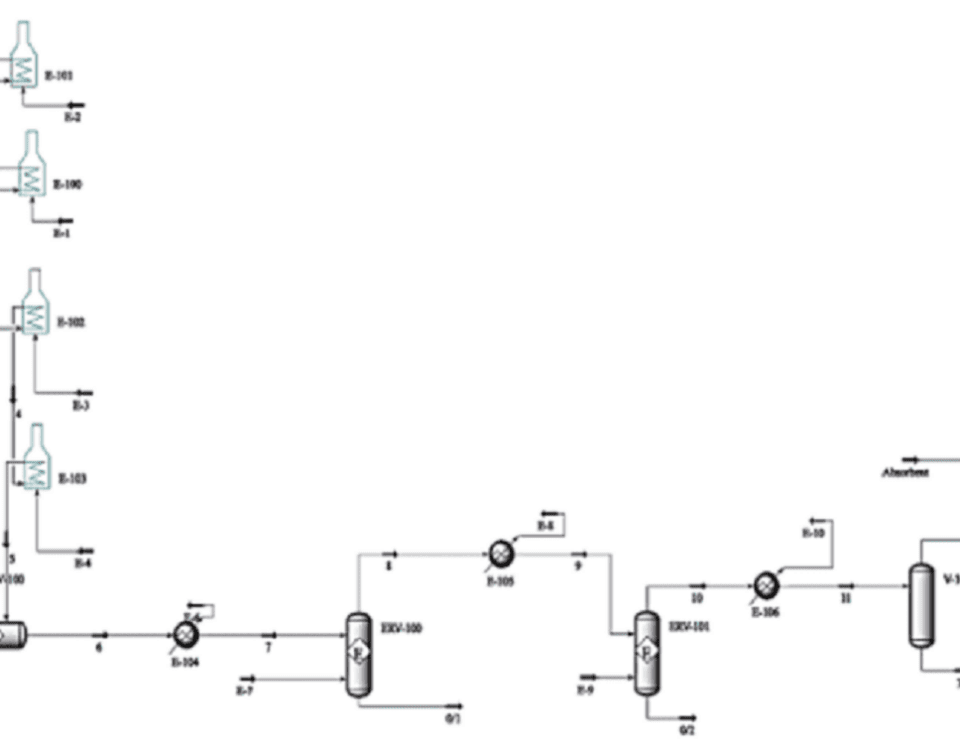

- Introduction Liquefied Natural Gas (LNG) refers to natural gas that has been temporarily converted into a liquid state for the purpose of storage or transportation in […]

- Introduction The primary feedstock for ammonia production units consists of sweet gases (primarily methane) and atmospheric nitrogen. Methane, when mixed with steam and subjected to a […]

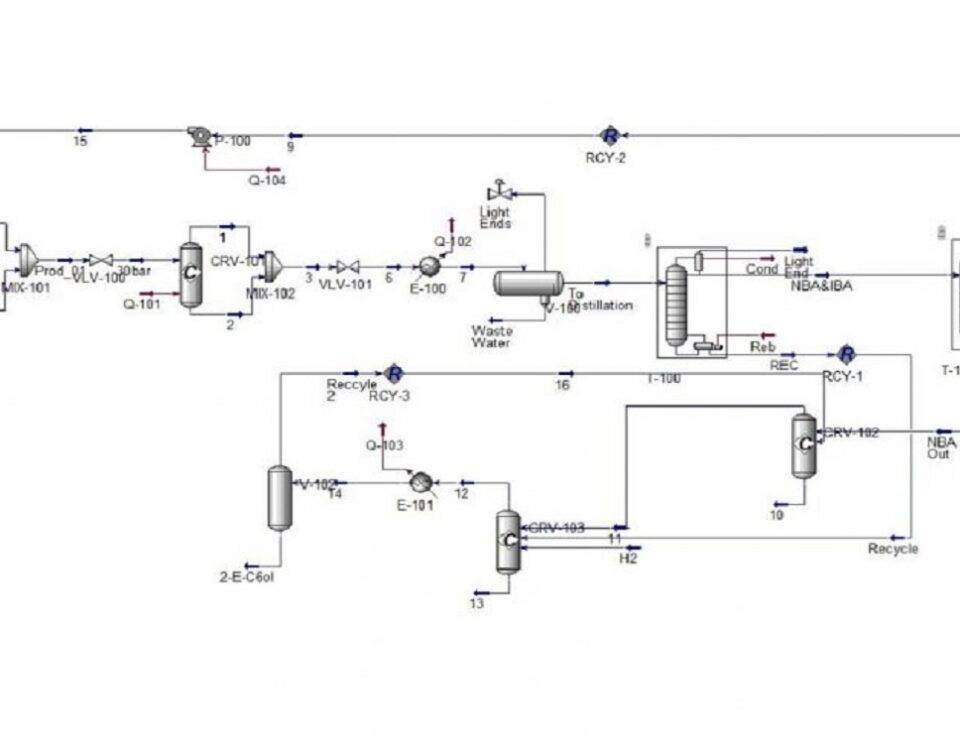

- Introduction 2-Ethylhexanol is a flammable liquid that can ignite when in contact with strong oxidizing agents. Appearing as a colorless, clear liquid, it is classified as […]

- Introduction Unlike traditional ethylene production processes that rely on steam cracking of naphtha, direct methane conversion technologies offer a promising alternative. However, these processes, which require […]

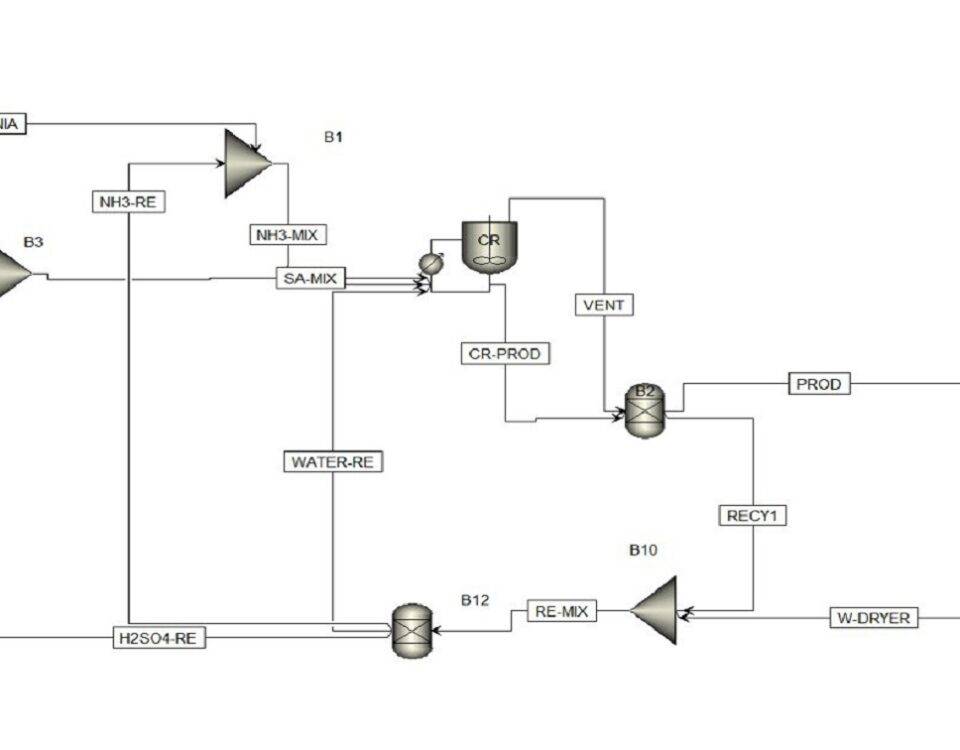

- Introduction Ammonium sulfate is a chemical compound formed by combining ammonia (an alkaline gas) and sulfuric acid (a strong acid). It typically appears as fine granules […]

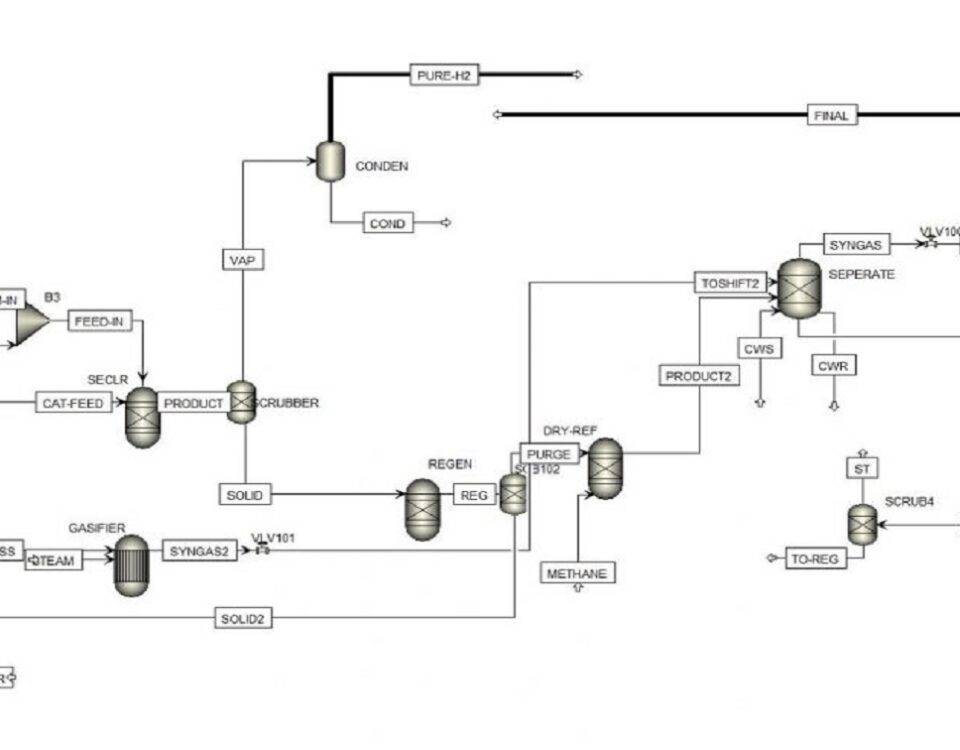

- Introduction Fossil fuel resources worldwide are rapidly depleting while global energy consumption continues to rise. This has increased the need for alternative and new energy sources. […]

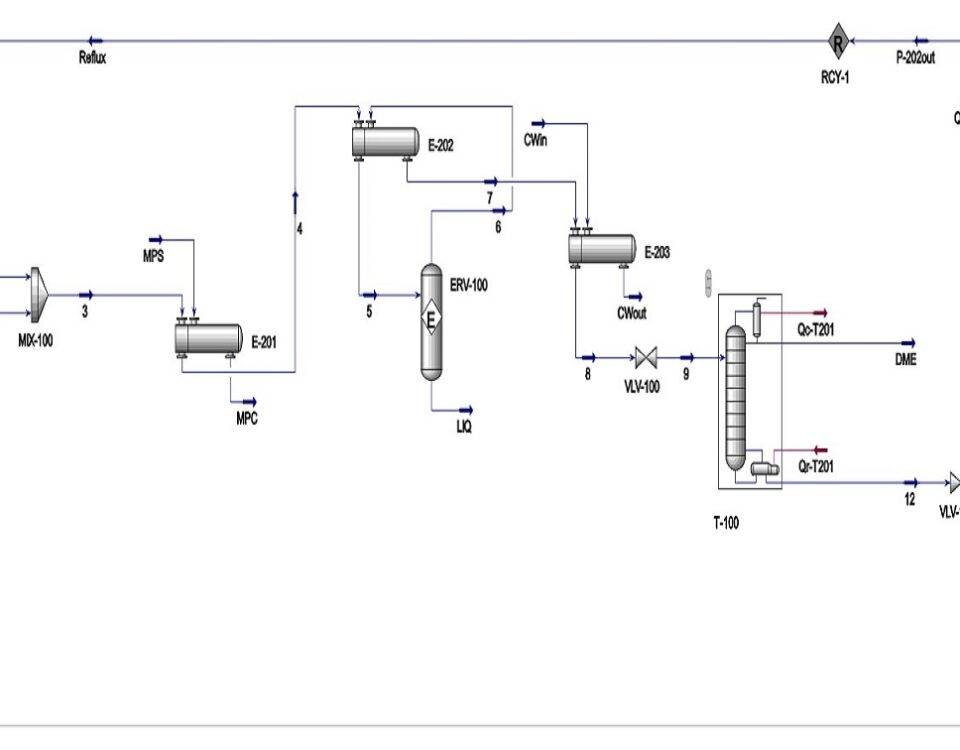

- Introduction Dimethyl ether (DME), the simplest aliphatic ether, is a colorless, ether-like odor, non-toxic, highly flammable gas that is soluble in water and alcohol. Also known […]

- Introduction The purpose of this project is to build a chemical plant that produces ethyl acetate which will be used as a solvent in synthetic fragrance […]

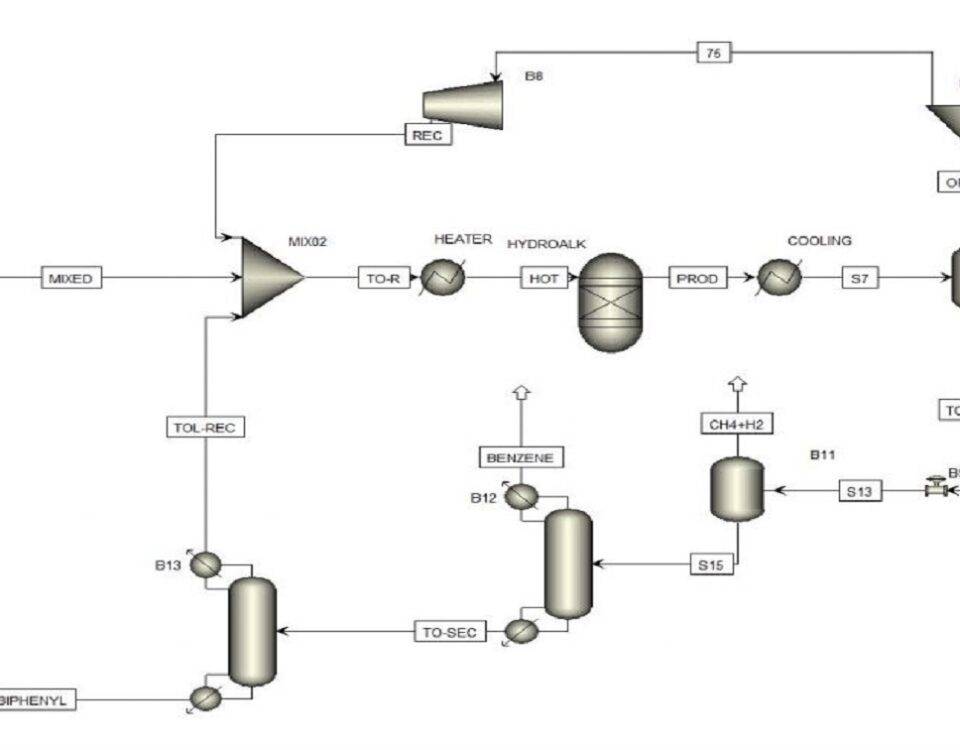

- Description Benzene is one of the most widely used substances in the world, which is used in the production of nylons, polystyrene, synthetic rubber, detergents, etc. […]

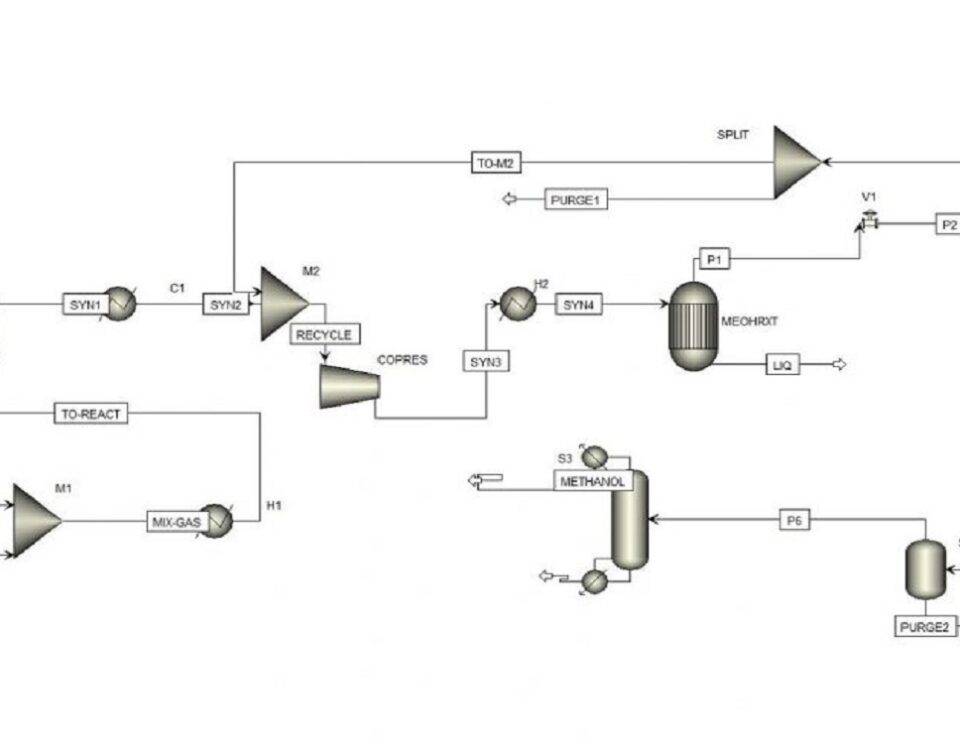

- Description Methanol, methyl alcohol, carbinol or wood alcohol, which is the simplest type of alcohol. It is known by the chemical formula CH3OH. Methanol is produced […]

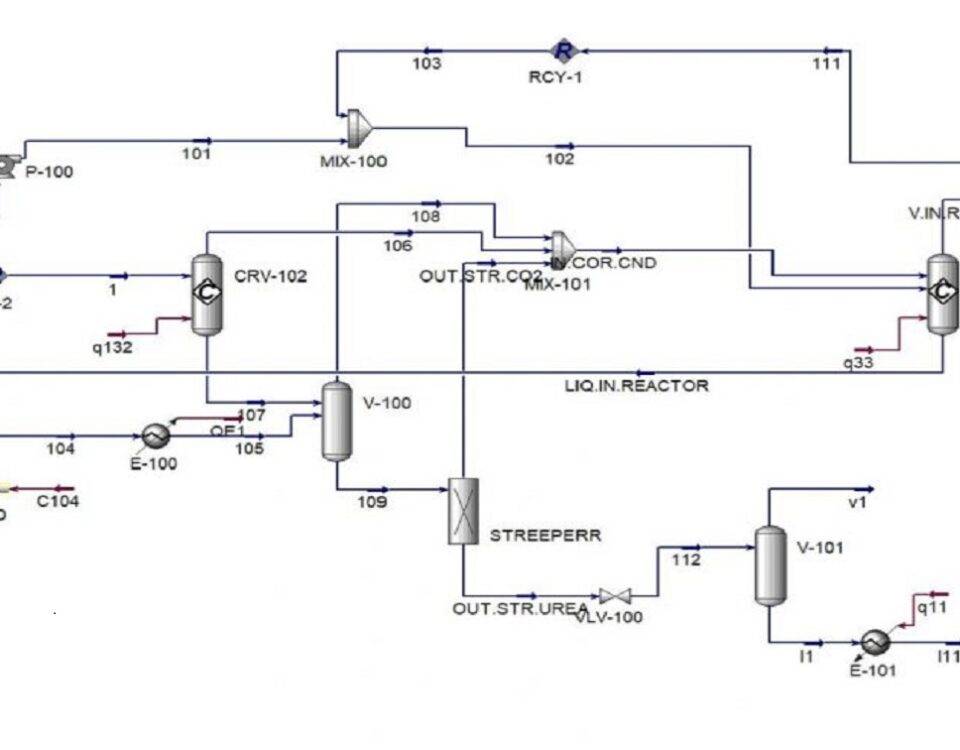

- Description Ammonium bicarbonate (commonly known as ammonium hydrogen carbonate) is a mild mineral compound and a common reagent in industrial and research methods. This substance is […]

- Description In this project, 8 theory questions have been done in Aspen Plus and Hysys software, which are as follows. Exercise 1 Question 1: Simulation of […]

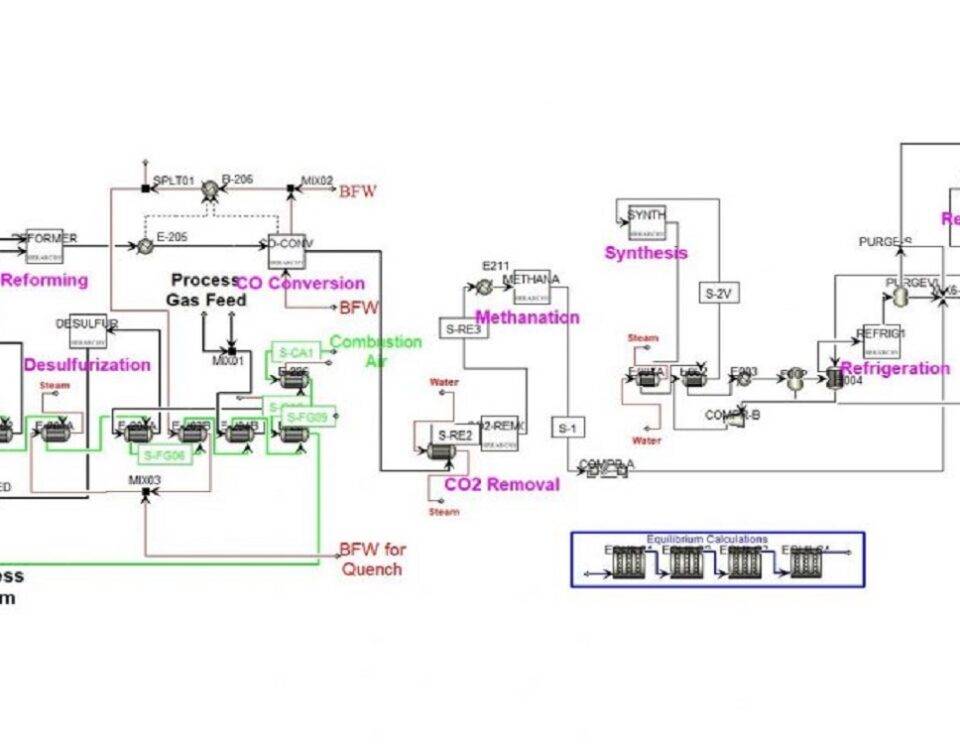

- Description The design of the Kermanshah Petrochemical Ammonia Unit is based on reducing the energy of the ammonia process, under the technical knowledge (license) of Kellogg […]

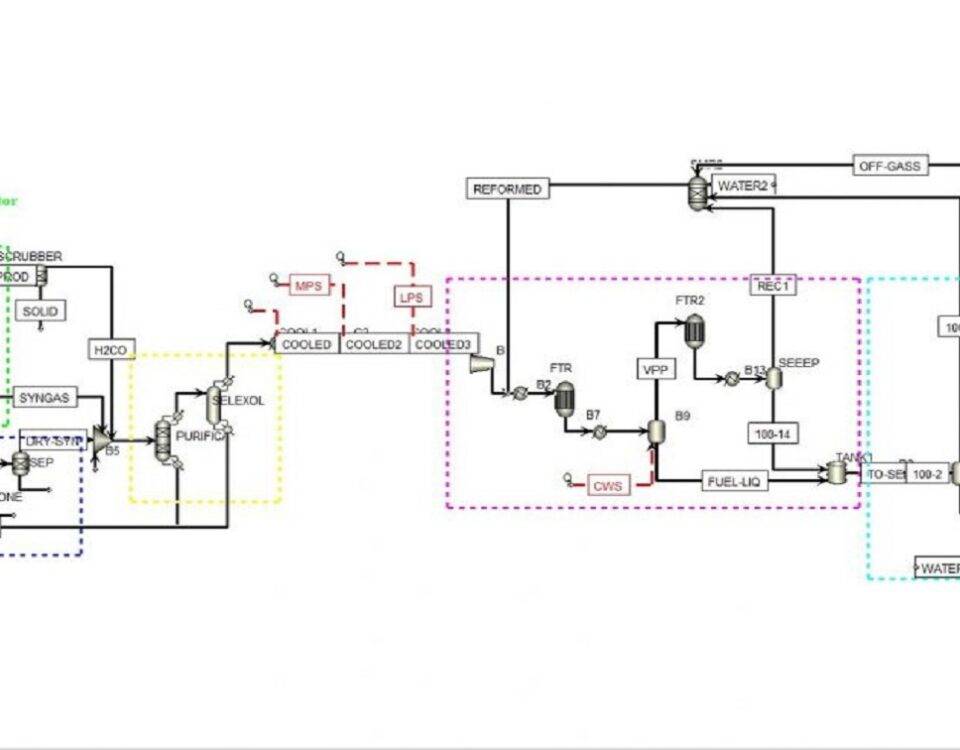

- Description Today, with the increasing demand for liquid fuels as well as the limitations of energy resources. It has caused a lot of attention to the […]

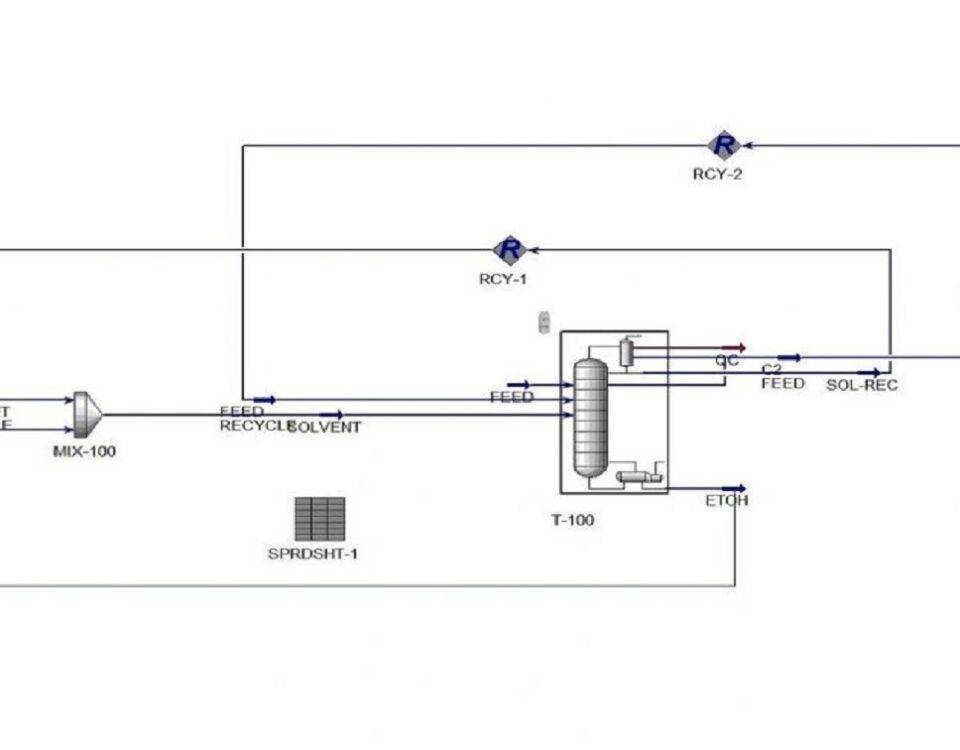

- Description Batch distillation is a common method for separating mixtures. However, azeotropic mixtures present a unique challenge as their components cannot be separated through simple distillation […]

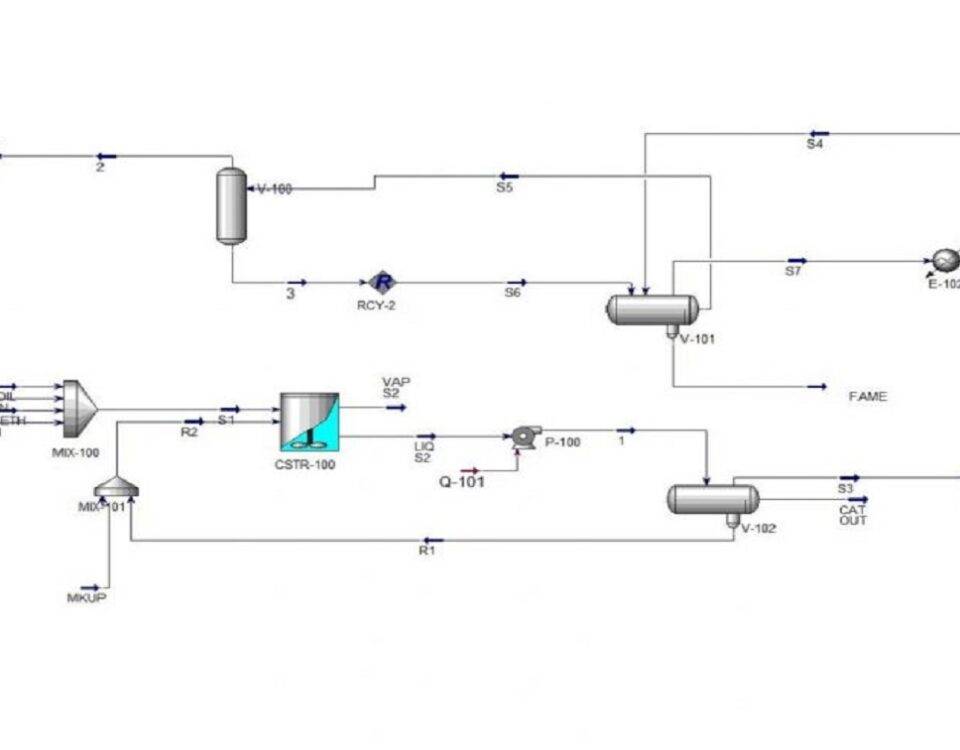

- Introduction Biodiesel is a type of fuel produced from the processing and modification of vegetable oils. Introduced in the 1970s as a substitute for petroleum diesel, […]

- Introduction Biodiesel, or biological diesel, is a type of fuel produced from the processing and modification of vegetable oils. This fuel was first introduced in the […]