Absorption Cycles: Comprehensive Review and Significance

Since their inception, absorption cycles have been widely studied by researchers worldwide, with extensive exploration of various configurations. Notably, absorption systems offer unique advantages and present a viable alternative to traditional vapor-compression refrigeration. In particular, they are valuable where efficient energy utilization, such as waste heat recovery, is crucial.

Common Working Pairs in Absorption Cycles

Absorption cycles utilize different working pairs, with the most common being water-ammonia and lithium bromide-water. Each pair serves distinct purposes and offers unique characteristics:

- Water-Ammonia: Primarily used in refrigeration to achieve very low temperatures, this pair provides advantages such as lower construction and maintenance costs and the ability to operate effectively at low temperatures. Furthermore, the water-ammonia cycle avoids crystallization issues that can arise in other systems, which makes it well-suited for specific refrigeration applications.

- Lithium Bromide-Water: By contrast, this pair is frequently used in air conditioning and temperature control systems. It is especially known for its stable performance at moderate temperatures, and it has become widely implemented in standard air conditioning systems.

Comparison of Ammonia and Lithium Bromide-Water Systems

In terms of historical development, ammonia-based absorption systems have been around longer than lithium bromide-water systems. Because of their extensive cooling capabilities and lower costs, ammonia systems are often preferred for industrial applications. Additionally, they offer unique advantages, such as eliminating crystallization concerns and enabling cooling at sub-zero temperatures. On the other hand, lithium bromide-water systems are particularly suited for environments with standard cooling requirements, thanks to their reliability and specific properties in air conditioning applications.

Additional Equipment in Ammonia Absorption Systems

To ensure efficient operation, water-ammonia absorption systems require additional equipment, such as distillation columns, to purify the refrigerant and prevent the absorbent from entering the evaporator. This equipment helps maintain system efficiency and stability by avoiding performance reduction due to the mixing of absorbent and refrigerant. In contrast, lithium bromide-water systems are typically simpler, requiring less supplementary equipment, which in turn simplifies their maintenance.

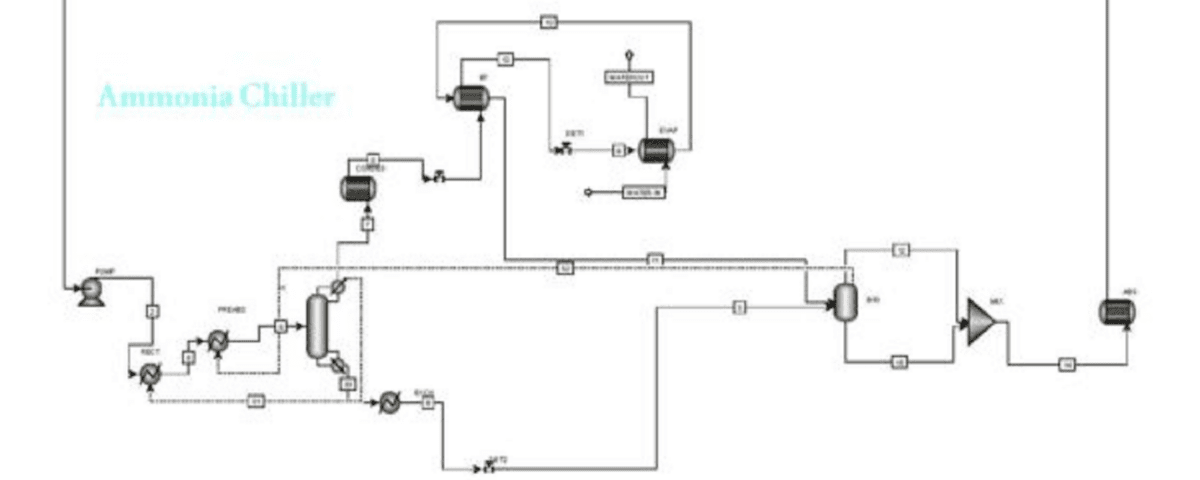

Simulation of Water-Ammonia Absorption Cycle Using Aspen Plus

This project simulates a water-ammonia absorption cycle using Aspen Plus software. Notably, Aspen Plus is an advanced tool widely utilized in chemical engineering and process industries to perform in-depth process analyses and improve system efficiency. For this simulation, the process data was sourced from the research paper by Mansouri et al. (2015), which offers comprehensive details on critical process parameters.

Advantages of Simulating Absorption Systems Using Aspen Plus

Simulating absorption systems in Aspen Plus provides engineers with several key benefits. These advantages include:

- In-Depth Analysis of Process Parameters: Through Aspen Plus, users can adjust and fine-tune essential parameters such as temperature, pressure, and flow rate, which facilitates overall system optimization.

- Early Issue Identification: Additionally, simulation at early stages enables the detection and prevention of potential issues, which helps reduce both operational and maintenance costs.

- Energy Optimization: Moreover, simulating absorption systems aids in optimizing energy resource usage, ultimately lowering fuel and energy expenses.

Conclusion

In summary, this project demonstrates the advanced capabilities of water-ammonia absorption systems in delivering efficient cooling while reducing energy costs. Furthermore, by using Aspen Plus in this simulation, engineers can achieve detailed analysis and process optimization, underscoring the significant value of this tool in the chemical and petrochemical industries.

Project Files

- Aspen Plus Simulation File

- Research Paper with Process Data