Description

Benzene is one of the most widely used substances in the world, which is used in the production of nylons, polystyrene, synthetic rubber, detergents, etc. The largest producers of benzene on a global scale are the United States, Canada and Japan. According to the country’s needs in different industries, benzene production has been developed in petrochemical industries and is carried out under different processes.

Toluene hydrodealkylation (HDA) is a process used to produce benzene. The main reaction in this process is:

![]()

As seen in the above reaction, a methyl group (CH₃) is detached from the toluene molecule and, along with a hydrogen atom, forms a methane molecule. Consequently, a benzene molecule is produced.

Reaction Conditions

Certain specific conditions are required to carry out the hydroalkylation reaction:

– Catalyst: Metal catalysts such as platinum and palladium are used to accelerate the reaction.

– Temperature: The reaction is conducted at high temperatures (typically between 500 to 660 degrees Celsius).

– Pressure: The reaction occurs at high pressures (usually between 20 to 60 bar).

Advantages of the Hydroalkylation Process of Toluene

– High Purity Benzene Production: This process is an efficient method for producing high-purity benzene.

– Use of Inexpensive Raw Materials: Toluene is a relatively cheap and readily available material.

– Flexibility: This process can easily respond to changes in the demand for benzene.

Applications of Produced Benzene

Benzene produced through the hydroalkylation of toluene is utilized in the production of many chemical products, including:

– Plastics: Such as polystyrene and nylon

– Dyes and inks

– Detergents

– Adhesives

– Pharmaceuticals

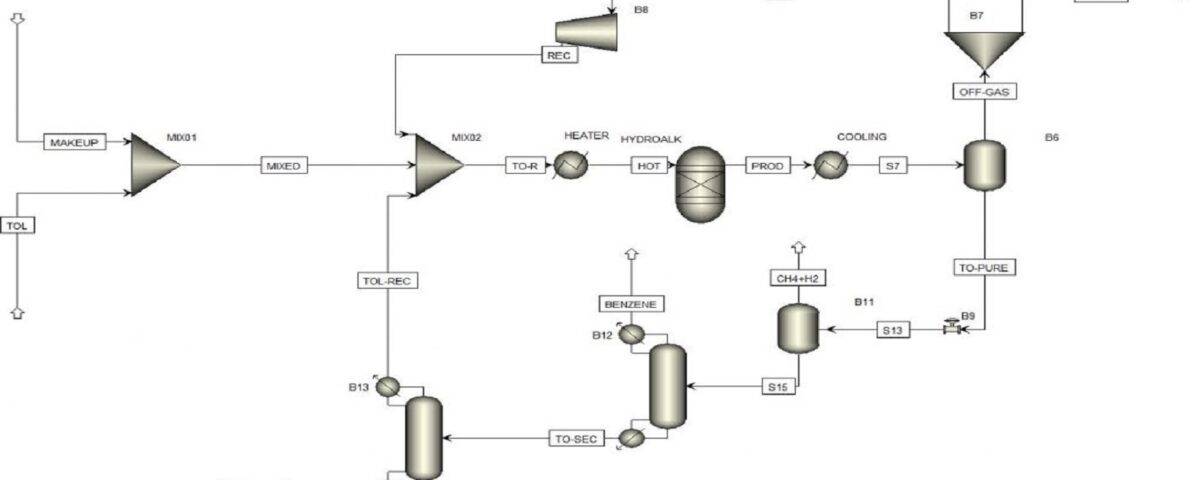

Process Simulation

To study and optimize the hydroalkylation process, simulation software such as Aspen Plus is used. These software tools allow engineers to simulate various operating conditions and determine the optimal conditions for benzene production. In this project, the novel hydro-dealkylation process of toluene for benzene production has been simulated using Aspen Plus.

For purchasing the project or for more information, please proceed through the link below.

In this project, the new process of hydrodialkylation of toluene to produce benzene is simulated in Aspen Plus software.