Introduction

Due to the ever-increasing demand for energy and environmental concerns caused by the release of pollutants, improving the quality of fossil fuels, including diesel, has become one of the most important challenges facing the petrochemical and automotive industries. One of the most important pollutants in diesel fuel is sulfur, which turns into sulfur oxides during the combustion process and causes air pollution, acid rain, and damage to engine equipment.

Adsorption (ADS) has been considered as an alternative and low-cost method that uses adsorbents such as activated carbon to absorb sulfur compounds in diesel fuel. The current research aims to evaluate the performance of activated carbon in the absorption of sulfur compounds from diesel fuel and accurate simulation models for this process under the development of our company.

Description of the process

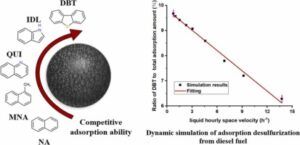

SANILCO investigated the adsorption of sulfur compounds from diesel fuel using activated carbon. They studied how aromatic and nitrogenous compounds affect the process and developed mathematical models for simulation. The results help in designing and optimizing diesel fuel refining processes for cleaner fuels.

Simulation description

In the simulation part of this project, the team of SANILCO Company has tried to model the behavior of the sulfur absorption process from diesel fuel more accurately. This work is being done using simulation software and numerical solution of differential equations. To meet the needs of simulation and design of adsorption processes, Aspen has developed Aspen Adsorption software. This software includes a flow graph operating system with different models and does not require advanced programming skills of the user. Therefore, in this research, Aspen Adsorption software was used to perform multicomponent adsorption simulations and optimize operating conditions.

General steps of simulation

In the present study, Aspen Adsorption software was used to perform dynamic simulation of ADS considering the inhibitory effects of polycyclic aromatic compounds (PAH) and nitrogenous compounds. Adsorption isotherms and failure curves of PAHs, nitrogen compounds and aromatic sulfur compounds are obtained to determine the adsorption and mass transfer isotherm models.

The effects of PAHs and nitrogen compounds on ADS are investigated and multicomponent adsorption isotherm model and mass transfer model are developed. Dynamic simulations are applied for further analysis as well as the design of a fixed platform for ADS from a conventional diesel fuel.

Determining the Parameters of the Model:

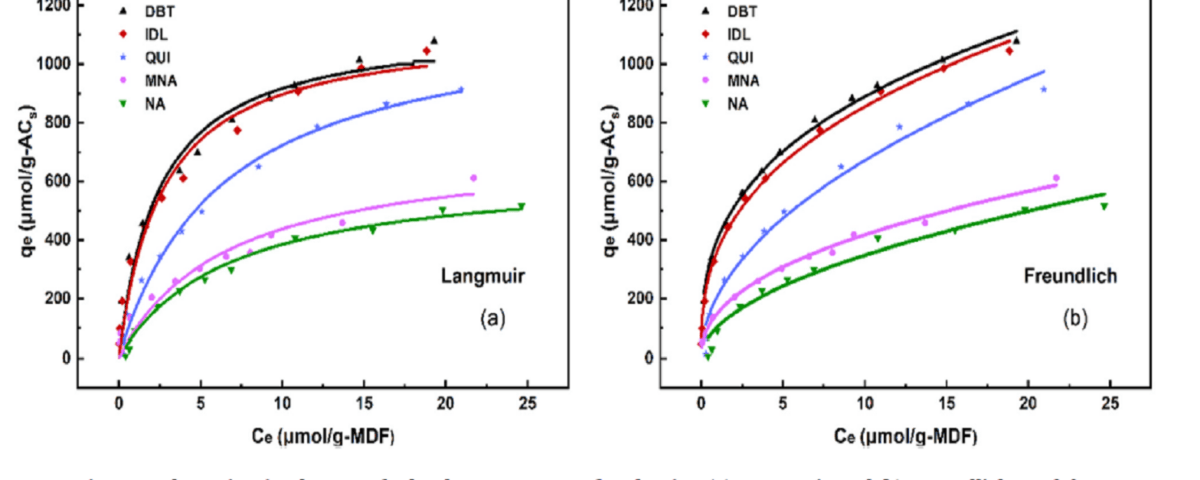

Adsorption Isotherms: The parameters of LANGMUIR and FREUNDLI isotherm models are determined using laboratory data obtained from equilibrium adsorption experiments. These parameters indicate the ability of activated carbon to absorb sulfur molecules as well as the interaction energy between sulfur molecules and the activated carbon surface.

Kinetic Parameters : Kinetic parameters such as mass transfer coefficients are also determined using laboratory data. These parameters control the transfer rate of sulfur molecules from the fluid phase to the surface of activated carbon and then their penetration into the pores of activated carbon.

Formulation of Differential Equations

Math balance Equation: In this section, a simplified model is presented to describe mass transfer in a fixed bed. This model is based on several simplifying assumptions, such as continuous fluid flow in the bed, constant temperature conditions, and no pressure drop. Mass balance differential equations are written for each component in the system (sulfur, solvent and activated carbon). These equations express the changes in the concentration of each component over time and at different points of the adsorption bed.

Boundary and initial conditions: Appropriate boundary and initial conditions are chosen for the system. The boundary conditions include the input and output concentrations of different components and the initial conditions include the initial distribution of concentrations inside the adsorption bed.

Numerical Solution of Equations:

Numerical Methods: Numerical methods such as finite difference or finite element methods are used to solve differential equations numerically. These methods convert differential equations into a system of algebraic equations that can be solved using computers.

Simulation Software: Specialized simulation software like COMSOL Multiphysics, MATLAB, or ANSYS is used to solve equations numerically. These software allow defining the system geometry, specifying material properties, setting boundary and initial conditions, and solving the equations numerically.

Interpretation of Results:

Concentration Distribution: By numerically solving the equations, the concentration distribution of each component within the adsorption bed over time is obtained.

Outlet Profile: Using the simulation results, the concentration profile of the outlet from the adsorption bed is obtained, which is compared with experimental data.

Effect of Different Parameters: By changing the model parameters, the effect of each parameter on the performance of the adsorption system is investigated

General conclusion

The research “Evaluation of the performance of activated carbon in the absorption of sulfur compounds from diesel fuel and the development of accurate simulation models for this process” is under the development of Anil Pars Company and is ongoing. By conducting experimental tests and numerical simulations, researchers have shown that activated carbon is an efficient adsorbent for removing sulfur compounds from diesel fuel. Also, the effect of various factors such as type of activated carbon, particle size, fuel flow rate and initial sulfur concentration on absorption efficiency has been investigated. Using the developed mathematical models, we will be able to predict the behavior of the absorption process and determine the optimal conditions to do this.