Introduction

Ethanol is a widely used chemical in various industries, including fuel, pharmaceuticals, food, and chemicals. However, the separation of ethanol from water, especially at the azeotropic point (where the liquid and vapor compositions are the same), poses significant challenges due to separation complexities and the need for advanced techniques. The ethanol-water azeotrope is a major barrier to obtaining high-purity ethanol, making specialized methods and precise simulations of the process under various operating conditions essential.

Process Description

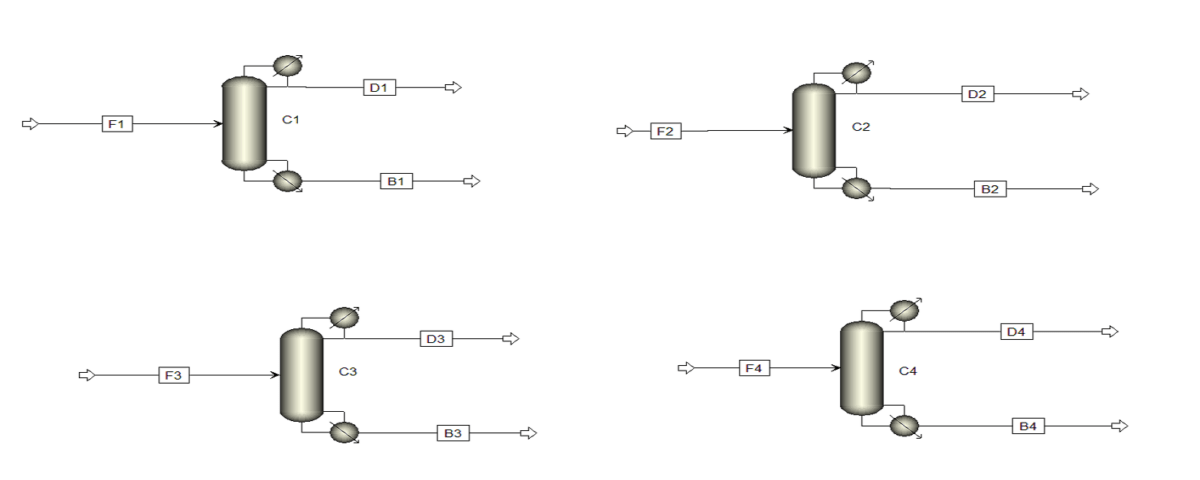

The separation of ethanol from water presents a significant challenge in the chemical industry due to the formation of azeotropes. This project employs four distillation units with varying operational conditions and feed concentrations to overcome this limitation. The main goal is to break the ethanol-water azeotrope and achieve high-purity ethanol.

In each distillation unit, a mixed feed of ethanol and water with varying percentages enters the distillation column, subjected to specific temperature and pressure conditions. Since the azeotropic point of the ethanol-water mixture changes with pressure, each distillation unit is carefully adjusted to apply the optimal pressure and temperature to effectively transcend the azeotrope. This is achieved through variations in pressure, adjusting the reflux ratio, and the number of distillation stages in each unit.

The overall process is designed to gradually increase ethanol concentration in the output stream through multiple distillation stages. Each distillation unit, by finely tuning its operating conditions, removes a portion of the water and transfers a more concentrated ethanol to the next unit. In this way, the azeotrope is progressively broken, yielding high-purity ethanol from the last distillation unit.

This process utilizes multi-stage distillation to provide an efficient and effective system for separating ethanol from water while optimizing energy consumption.

Simulation Description

In this project, the simulation of the azeotropic separation of ethanol from water is conducted in Aspen Plus software. The objective is to evaluate the performance of four independent distillation units under various operating conditions to achieve high-purity ethanol.

Thermodynamic Modeling: An advanced model is employed to accurately predict the behavior of the ethanol-water mixture, which exhibits non-ideal behavior. This model accounts for the complex interactions between ethanol and water molecules and effectively simulates phenomena like azeotrope formation. It allows us to predict the behavior of the mixture under different temperature and pressure conditions.

Feed and Operating Conditions Definition: For each distillation unit, feeds with varying ethanol and water concentrations are defined. Each unit’s operating conditions, including pressure, temperature, and the number of distillation stages, are tailored to effectively separate the ethanol-water azeotrope and produce high-purity ethanol.

Process Simulation: Each distillation unit is simulated independently. Inputs, including feed, temperature, pressure, and reflux ratio, are specified, while outputs consist of overhead and bottoms streams with varying ethanol and water concentrations. Simulations indicate that slight changes in operating conditions can lead to incremental increases or decreases in ethanol purity.

Simulation Results Evaluation: The results from each distillation unit simulation are examined individually, focusing on the feasibility of achieving high ethanol purity. The results indicate that the operating conditions of each distillation unit are precisely calibrated, allowing for the attainment of the desired ethanol purity.

Conclusion

This project demonstrates the necessity of utilizing separate distillation units with varying operating conditions for achieving high-purity ethanol from water in the presence of an azeotrope. The simulations in Aspen Plus accurately predict system behavior and identify the optimal conditions for effective separation. The findings can serve as a foundation for optimizing industrial processes and reducing energy consumption in similar distillation units.

Ethanol Purification and Separation from Water in Aspen Plus

In this project, the purification and separation of ethanol from water in Aspen Plus were simulated using four distinct distillation units with varied operating conditions and input compositions. Additionally, the project includes detailed training and explanations for a better understanding of the simulation process and result analysis.