Description

Gas condensate after separation from natural gas contains volatile elements from light hydrocarbons such as methane, ethane, etc. If they are placed in suitable environmental conditions. They can be separated from the liquid phase and cause the system to become biphasic and join the gas phase. This will have adverse effects on product quality, storage and transportation. Therefore, in order to achieve optimal conditions for storage, transfer and sale, the liquid must be stable in a single phase. The set of these stabilization operations is called Condensate Stabilization.

This operation is done for three reasons:

1. It is the removal of light and volatile hydrocarbons (volatile elements) or in other words the recycling of methane, ethane, propane and to a large extent butane or LPG from the flow of liquid hydrocarbons (gas condensate).

2. Reducing the fluid vapor pressure and bringing it to a certain RVP (Reid Vapor Pressure) as a technical characteristic, so as to prevent the two-phase fluid.

RVP

RVP is a special method to determine the type of hydrocarbon cuts. In the Reid method, hydrocarbon fluid is placed in a chamber with variable pressure. Then it is heated to a temperature of 73.8 degrees Celsius. After some time, the high pressure of this fluid is fixed. This pressure determines the RVP of the fluid. In other words, RVP can be defined as the liquid vapor pressure in equilibrium with the liquid phase at a temperature of 73.8 degrees Celsius, which is lower than the ambient pressure.

in such a way that it is placed in the single-phase liquid region during transportation and storage. The amount of RVP will be different in the hot and cold seasons of the year due to the change in the amount of compounds that make up the hydrocarbon flow. This amount is about 12 psia for winter season and about 10 psia for summer season.

3. Reducing the amount of water with condensate to less than 500 ppm and removing mercaptan and acidic elements from the fluid. (Of course, it should be mentioned that gas condensates naturally contain very small amounts of H2S CO2 compared to gaseous hydrocarbon flow).

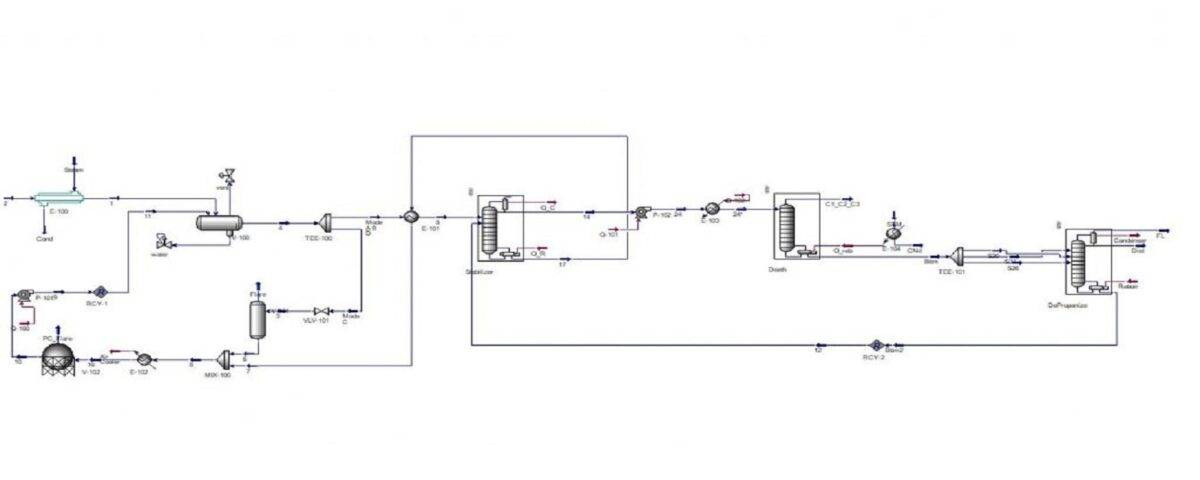

Simulation & Optimization of Stabilization Unit of VALIASR Refinery

In this project, the gas condensate stabilization unit of Vali Asr Kangan Refinery is simulated. The simulation was done based on the data and industrial maps of the refinery, and at the end, partial optimization was done with the help of Aspen Hysys. Also, a video tutorial on how to optimize is provided in this project.