Introduction

The petrochemical industry, as a key economic driver, produces essential raw materials used across various aspects of daily life. Within this sector, cooling processes play a crucial role in maintaining temperature and pressure control, product quality, and overall system efficiency. The cooling unit at Arya Sasol Petrochemical Company, which utilizes propylene as a primary input, requires meticulous optimization to improve efficiency and reduce costs.

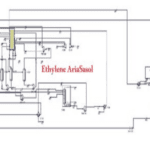

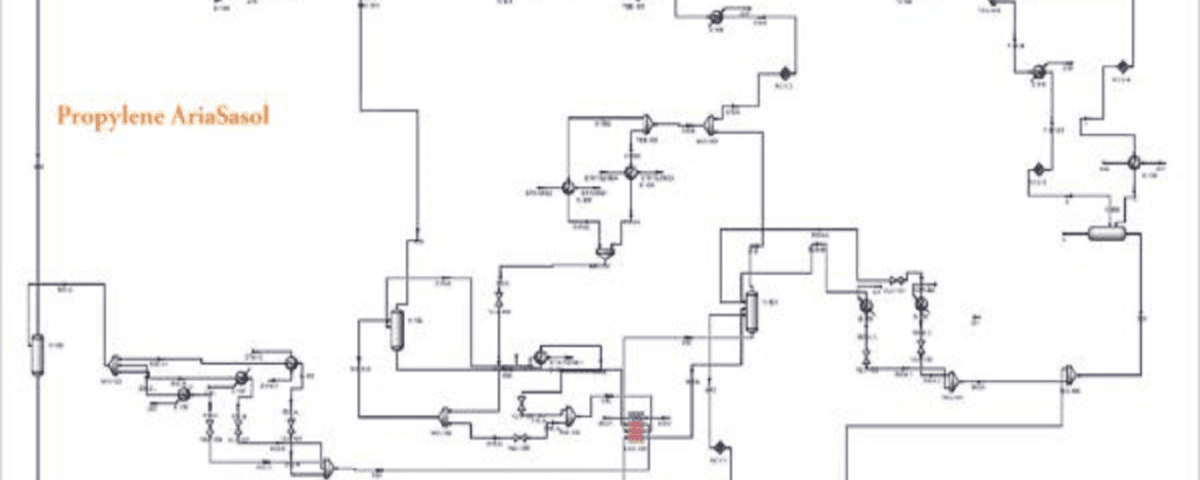

Simulating cooling processes with industrial software such as Aspen HYSYS provides a powerful tool for designing and analyzing these processes in depth. This software allows us to model system behavior under varying conditions, identifying strengths and weaknesses effectively.

Exergy analysis is an important tool for assessing process efficiency, helping to gain insight into energy losses and related thermodynamic factors.

Details

Arya Sasol Polymer Company, equipped with state-of-the-art facilities, annually produces 1,100,000 tons of ethylene in its olefin unit, 375,000 tons of low-density polyethylene (9 grades licensed by Stamicarbon, Netherlands) in the LDPE unit, and 375,000 tons of medium and high-density polyethylene (10 grades licensed by Basell, Germany) in the MD/HDPE unit.

Conclusion

In this study, we simulated the cooling process of Arya Sasol Petrochemical’s unit using propylene, combined with exergy analysis to assess and optimize system performance. Results indicate that Aspen HYSYS simulation allows for accurate evaluation of operating conditions, helping to pinpoint process strengths and weaknesses. This tool enabled us to study the impact of changing key parameters on system performance.

Moreover, exergy analysis, as an innovative approach, helped us understand energy losses within the cooling process. Identifying these losses led not only to energy optimization but also to reduced operational costs and improved environmental sustainability for the unit.

The analysis demonstrated that optimizing operating conditions and the efficient use of propylene can improve efficiency and reduce energy consumption. These achievements will not only increase the economic productivity of Arya Sasol but also enhance the overall performance of the country’s petrochemical sector.

Ultimately, the findings of this study can serve as a basis for future research on optimizing petrochemical processes, focusing on innovative technologies and minimizing the environmental impact of the petrochemical industry. Further engineering studies on new technologies and innovative methods for energy optimization and resource reduction in petrochemical units are recommended.

Available Files

The available files include the exergy analysis Excel file, simulation file, and industrial PFD diagrams.