Description

Temperature Swing Adsorption (TSA) is a process that involves the separation and purification of gases and liquids. It functions by utilizing a solid adsorbent, such as zeolite, activated carbon, or silica gel, which has the ability to attract and hold specific molecules onto its surface. This process is highly sensitive to temperature variations.

How Does a TSA Unit Work?

The TSA process typically involves two primary stages:

- Adsorption: In this stage, a gaseous or liquid mixture containing various components comes into contact with the adsorbent. At low temperatures, the adsorbent strongly attracts the desired molecules, separating them from the other components.

- Desorption: Once the adsorbent becomes saturated, the temperature is increased. This causes the adsorbed molecules to be released from the adsorbent’s surface, returning them to the gas or liquid phase. By repeatedly cycling through these two stages, different components of a mixture can be separated and purified.

Applications of TSA in Refineries

TSA units play a crucial role in refinery processes. Due to their ability to accurately and selectively separate different molecules, they are employed in various stages of the refining process.

Key applications of TSA units in refineries include:

- Gas purification: Separating light gases like hydrogen, nitrogen, and oxygen from gaseous mixtures. This is particularly important in producing high-purity industrial gases.

- Gas drying: Removing moisture from natural gas and petroleum products. Moisture can cause various problems in subsequent processes.

- Acid gas treatment: Removing acidic gases like hydrogen sulfide (H₂S) and carbon dioxide (CO₂) from gas streams. These gases can contribute to corrosion and environmental pollution.

- Light hydrocarbon separation: Separating light hydrocarbons such as methane and ethane from hydrocarbon mixtures. This separation is essential for producing high-value products like propane and butane.

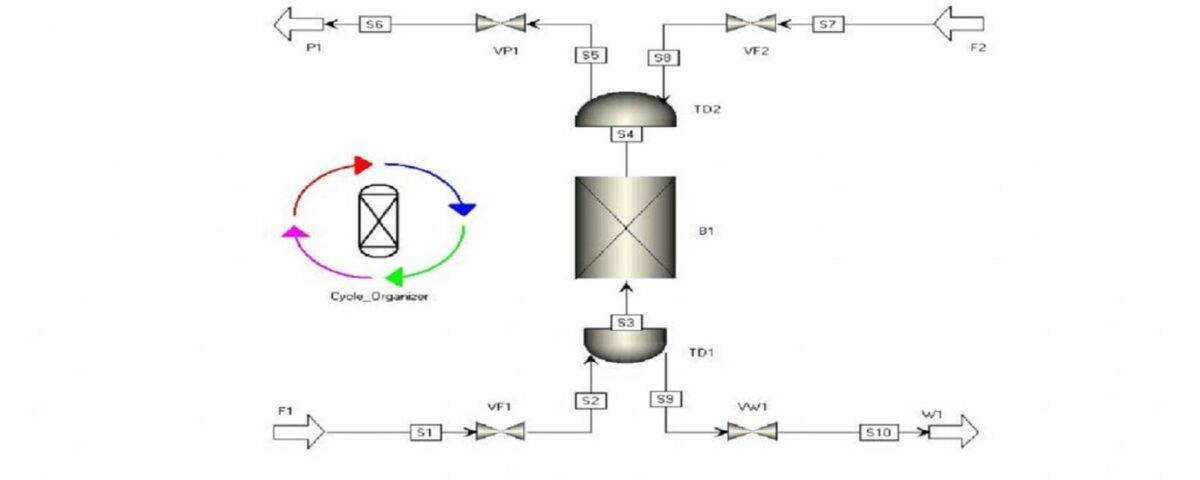

In this project, the simulation of hydrogen separation process based on surface adsorption by pressure-temperature alternation method (PTSA) was done using Aspen Plus software.This project has full simulation training of TSA unit in ADSIM Aspen Plus software.

Conclusion

TSA (Temperature-Switched Surface Adsorption) units are known as the beating heart of many refineries. These units, utilizing advanced and efficient technology, play a significant role in improving the quality of final products, increasing the efficiency of refining processes, and reducing environmental pollution.