Introduction

This company is considered as the largest gas refinery in the country. The design and initial capacity of this company was 85 million cubic meters per day. With the implementation of development plans, the current capacity of this company has reached 125 million cubic meters. The average operating capacity of this refining company in 2012 was equal to 85 million cubic meters per day, which has a 20% share in the country light gas production. This refinery is located in Bandar Taheri (Siraf) in Bushehr province.

The company’s products include light gas, petroleum liquids or gas condensates, and liquefied petroleum gas (LPG). The feed used in this refinery is supplied from Nar, Kangan gas fields and phases 6, 7 and 8 of South Pars. Operating area of Nar and Kangan includes two gas fields, Nar and Kangan. And it has a total of 73 productive wells. The production capacity of these two fields is about 90 million cubic meters per day.

Description of The Process

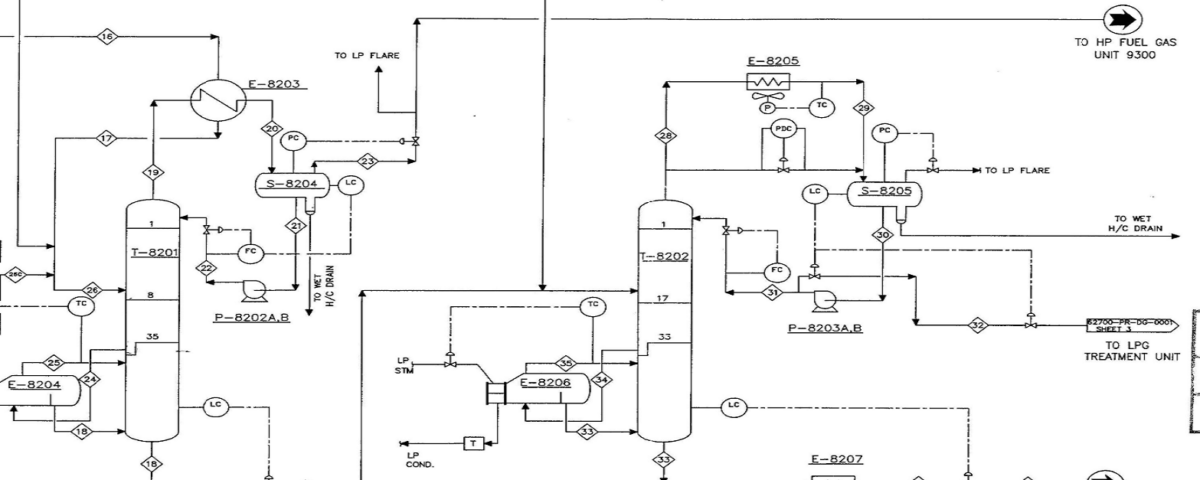

Distillation towers such as tower 8201 play a key role in separating different components of crude oil and intermediate products. The general steps of simulating 8201 tower in Aspen Hysys are as follows:

– Gathering detailed information about the input feed to the tower (composition, flow rate, temperature, pressure),. physical characteristics of the components of the feed, operating conditions of the tower (pressure, temperature at each stage) and expected products.

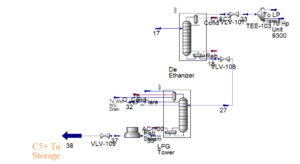

– Creating a process model in the software by defining the components in the feed,. creating process units (tank, pump, heat exchanger, distillation tower, etc.) and connecting them to each other.

– Precise adjustment of tower parameters such as the number of trays, type of trays, tower diameter, efficiency of trays, inlet steam flow rate, outlet flow rate and steam to liquid ratio.

– Performing molar balance calculations in each stage of the tower to determine composition and flow rate of the incoming and outgoing streams of each tray and analyzing the results to evaluate performance of the tower. comparing with operational data and identifying weaknesses and strengths of the design.

Conclusion

The simulation of tower 8201 using Aspen Hysys is considered a powerful tool for deep understandin of the operation of this tower and optimization of the production process in Fajr Jam refinery. Using this software, engineers can accurately and efficiently model complex refinery processes. and make better decisions to improve productivity and reduce costs.

Simulation of Tower 8201 of Fajr Jam Refinery by Aspen Hysys

In this simulation project, Tower 8201 of Fajr Jam Refinery is simulated by Aspen Hysys in Aspen Hysys version 14 software. The project has full training.