Introduction

The Claus process (SRU) is the primary sulfur removal process in petrochemical industries. It extracts elemental sulfur from hydrogen sulfide present in natural gas and gases produced as byproducts during crude oil refining. Currently, a significant portion of the world’s sulfur demand is met through this process, making the Frasch process less common. This process was invented by Carl Friedrich Claus, a German chemist residing in England, and patented in 1883. After the Claus process, the SCOT process is employed in refineries, which handles oxidation and separation.

Simulation of SCOT Process

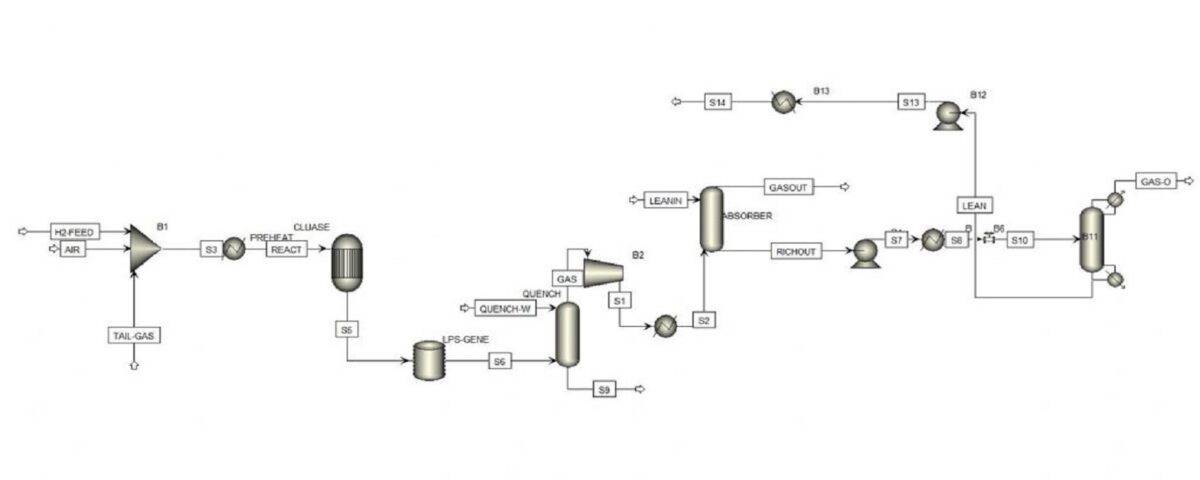

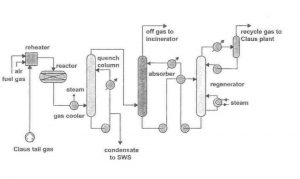

The simulation of the Shell Claus off-Gas Treating (SCOT) process using ASPEN Plus is a multi-stage process that involves modeling the effects and performance of various units in the treatment of off-gases. In this simulation, initial inputs such as the composition of the inlet gases, temperature, and ambient pressure are defined. Then, using various modules available in ASPEN Plus, the stages of chemical reactions and physical interactions between different components are modeled.

Subsequently, the separation and reaction units are defined, which include the reactions of sulfur and sulfur compounds. In the next stage, operating conditions for each process unit, such as inlet and outlet temperatures and pressures, along with operational statuses, are specified. Finally, the simulation results are examined and analyzed to assess the performance of the process and its overall efficiency in removing sulfur and other pollutants from the off-gases. This simulation process can significantly aid in optimizing system design and increasing productivity in industrial units.

Detailed process information can be obtained from the following article links:

SCOT Process Simulation In this project, the SCOT process has been simulated using the Aspen Plus software. The simulation utilizes data from the following two articles.

Simulation of the Process of Biological Removal of Hydrogen Sulfide from Gas

A Simulation of a Claus Tail Gas Treatment Unit in a Petroleum Refinery

Conclusion

The simulation of the Shell Claus off-Gas Treating (SCOT) process using ASPEN Plus demonstrates that this modeling approach can effectively assist in optimizing and evaluating the performance of off-gas treatment units. The analysis of the simulation results indicates a high efficiency in removing pollutants, particularly in reducing sulfur compounds, which significantly contributes to improved air quality and mitigates the environmental impacts of this process.

Additionally, the simulations conducted provide the opportunity to identify weaknesses and optimize operating conditions, which can lead to reduced operational costs and increased system efficiency. Consequently, this method serves as a practical and essential tool for engineers and designers aimed at enhancing industrial processes and improving their sustainability and performance.