Introduction

Plastics encompass a vast array of polymeric materials, constituting approximately 56% of all industrial polymers. Deriving from the Greek word “plastikos” meaning “capable of being molded,” plastics have found widespread application in industry due to their lightweight and durability. However, their recalcitrance to biological and chemical degradation has made them a significant contributor to the global waste problem.

The utilization of plastics predates the discovery of synthetic plastics. The industry experienced a pivotal growth phase from 1932, marked by advancements in five primary thermoplastics: polyethylene (PET), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and polymethyl methacrylate (PMMA).

Given their non-degradable nature, when different types of plastics are melted together, they tend to phase separate, similar to immiscible liquids like water and oil. These phase boundaries introduce structural weaknesses in the resulting material. The broad spectrum of plastic production, particularly for materials like polypropylene and polyethylene, poses challenges for recycling due to their inherent incompatibility. To overcome these phase separation issues in recycling, polymeric “molecular stitches” or “macromolecular welding agents” have been investigated as potential solutions.

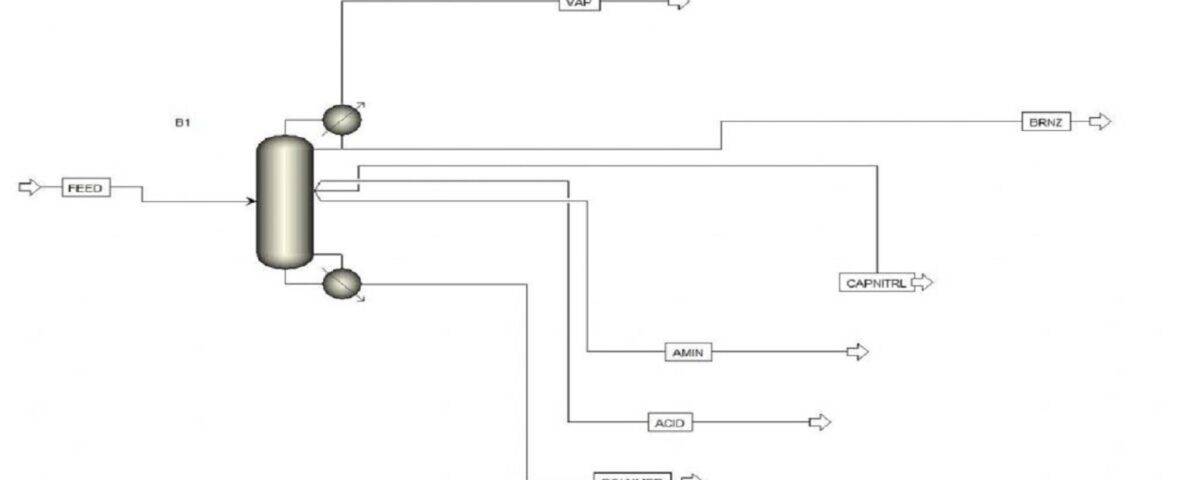

Simulation and Design of a Paraffin Separation Column

Plastics and nylon are derived from heavy petroleum fractions and various polymers. Combustion processes in boilers and furnaces also generate harmful gases such as carbon dioxide, nitrous oxide, hydrogen sulfide, and other carcinogens. Notably, a solid residue (char) is also produced as a byproduct of combustion.

To address these considerations, appropriate assumptions must be made and a suitable software selected for simulation and design. Given the nature of the outlet stream from the combustion chamber, Aspen Plus V10 or later versions are highly recommended due to their robust polymer simulation capabilities.

This project involves the simulation and design of a paraffin separation column with Aspen Plus. A comprehensive report accompanies the project.