Description

Biodiesel is an alternative fuel to petroleum diesel that is produced from renewable resources such as vegetable oils. This green fuel can be used in any compression-ignition engine, similar to traditional diesel and petroleum. From a technical standpoint, biodiesel is a fuel designed for diesel engines and consists of alkyl esters of fatty acids.

History of Biodiesel The use of biodiesel in diesel engines dates back to the invention of the first diesel engine. In fact, Rudolf Diesel, the inventor of the diesel engine, initially used peanut oil to power his engine. This is considered the first recorded use of biodiesel. Additionally, the French company Otto used peanut oil in a diesel engine at the Paris World’s Fair in 1990.

Environmental Benefits of Biodiesel

- Reduced Emissions: Biodiesel significantly reduces the emission of harmful pollutants, making it an environmentally friendly option.

- Renewable: Produced from renewable resources like vegetable oils.

Characteristics

- Compatibility with Diesel Engines: Biodiesel can be used in diesel engines without requiring modifications.

- Blending with Petroleum Diesel: It can be blended with petroleum diesel in any proportion to enhance its properties.

- Similar Performance: Biodiesel offers comparable performance to petroleum diesel in various applications.

- Diverse Feedstocks: Beyond vegetable oils, biodiesel can be produced from animal fats, used cooking oils, and even algae.

Production Process

Biodiesel is produced through a chemical reaction between a lipid (such as vegetable oils or animal fats) and an alcohol. The byproduct of this reaction is glycerol.

Applications

- Vehicle Fuel: Biodiesel can be used as a fuel for diesel engines.

- Fuel Blending: Biodiesel can be blended with petroleum diesel to improve fuel quality and reduce emissions.

Advantages of Biodiesel

- Reduced Fossil Fuel Dependency: The use of biodiesel can decrease reliance on petroleum.

- Improved Air Quality: Biodiesel reduces the emission of harmful pollutants, improving air quality.

- Support for Local Economies: The development of biodiesel production can create jobs and stimulate rural economies.

Primary Feedstocks for Biodiesel Production

The primary feedstocks used in biodiesel production include soybeans, canola, sunflower seeds, corn, animal fats, and waste oils (cooking oils and restaurant grease). Vegetable oils from soybeans, canola, corn, etc. are high-quality feedstocks for biodiesel production due to their high triglyceride content (92-99%) and low free fatty acid (FFA) content (less than 2%). Waste oils, including used cooking oils from restaurants, food industries, and households, typically have higher FFA and water content, and lower triglyceride content compared to fresh vegetable oils.

Due to the high FFA and water content in waste oils, they often require pretreatment to remove water and convert FFAs into esters. The global production of waste cooking oils in 2007 exceeded 15 million tons. While utilizing waste vegetable oils (yellow grease), FFAs can pose several challenges. A free fatty acid is a molecule that has been separated from a glycerol molecule, often as a result of the breakdown of oil molecules after numerous cycles of use. FFAs present four significant problems:

- Increased catalyst requirement: Higher FFA content necessitates more catalyst, increasing production costs.

- Soap formation: Soap (a fatty acid salt) is formed, complicating product washing.

- Water formation: Water formation slows down the main reaction.

- Reduced conversion: FFAs do not convert into fuel, lowering the overall yield.

When the FFA content in oil is less than 2.5%, these issues become less significant. Generally, the heat of combustion, cetane number, melting point, and viscosity of fatty compounds increase with increasing chain length and decrease with increasing unsaturation. For high-quality fuel production, a high oleic acid content is desirable.

Methods of Biodiesel Production

1.Microemulsion or Emulsification:This method involves creating a stable dispersion of one liquid in another, typically using surfactants.

2.Thermal Cracking (Pyrolysis):This process involves breaking down organic material into simpler substances through high temperatures in the absence of oxygen.

Second-Generation Biodiesel Production from Microalgae Using Pyrolysis

One of the biggest challenges in biodiesel production is the need for vast agricultural land to cultivate oil-producing plants. Microalgae have emerged as an alternative source for the oil required in biodiesel production. These single-celled organisms grow rapidly and some species contain high levels of oil. Microalgae can be cultivated in various aquatic environments, reducing the need for agricultural land. Additionally, microalgae can absorb carbon dioxide and use it as a carbon source for growth. Methods like photobioreactors and open ponds can be used to cultivate microalgae. The oil extracted from microalgae can be used to produce biodiesel, while the remaining biomass can be used for other products like animal feed and biogas.

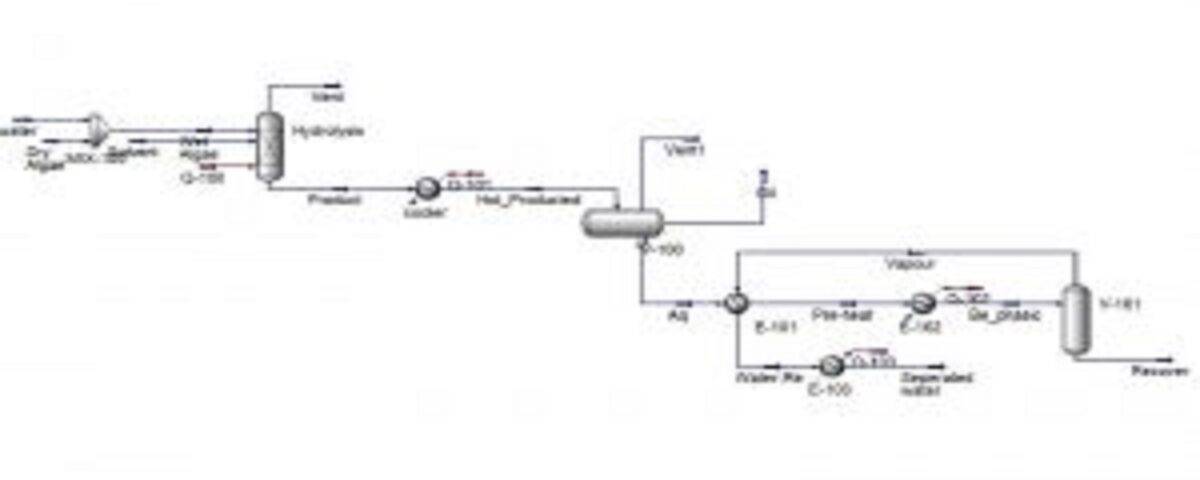

Simulation of Biodiesel Production from Microalgae

Given the growing challenges of declining fossil fuel resources and increasing environmental pollution, the search for clean and renewable fuels is more urgent than ever. Microalgae, as photosynthetic unicellular organisms, have great potential for biodiesel production and can play a significant role in the transition to clean energy.

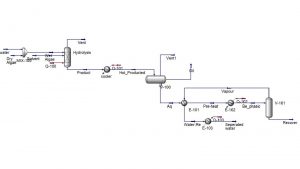

In this research, we have used the powerful process simulation software Aspen HYSYS to create a comprehensive model of biodiesel production from microalgae. This simulation not only provides a deeper understanding of the complex mechanisms involved in biodiesel production but also allows for the evaluation and optimization of various operational parameters.

This simulation is done with the help of the following two articles.

Biodiesel production from microalgae: ionic liquid process simulation

Evaluation of Hydrolysis Esterification biodiesel production from wet microalgae