Description

Surface adsorption has been considered in the industry due to its high efficiency, low cost and wide range of adsorbents for the separation of gas mixtures. Surface adsorption process is a periodic process. After absorbing the components on the surface, the absorbent must be regenerated from the absorbed components.

The regeneration operation occurs at low pressure, then the adsorbent is regenerated for the process of adsorption and repulsion. In this project, we will simulate the process of separating nitrogen from air. The process of separating nitrogen from air includes the following steps.

1. Increasing The Ambient Air Pressure Through The Compressor:

In this stage, which is the stage of air compression and initial preparation. Ambient air is transferred to air compressors and its pressure increases to a certain level (up to about 8 to 9 bars).

2. Passage of Compressed Air Through The Dryer for Drying:

After passing through the dryer and water trap, the compressed air loses a significant percentage of the moisture and suspended oil present.

3. Passage of Compressed Air Through The Activated Carbon Tower:

Because despite the filtration of the compressed air, there may still be some oil droplets and moisture in the air. As the air passes through the series microfilters in the active carbon tower (active carbon absorber). the remaining moisture and oil are completely absorbed and the air is completely dry, clean and compressed to the columns of the nitrogen generator.

4. Compressed Air Storage Tank:

Air enters the storage tank after the preparation process. The air tank installed here controls the volume of air required for the PSA generator and stabilizes this flow.

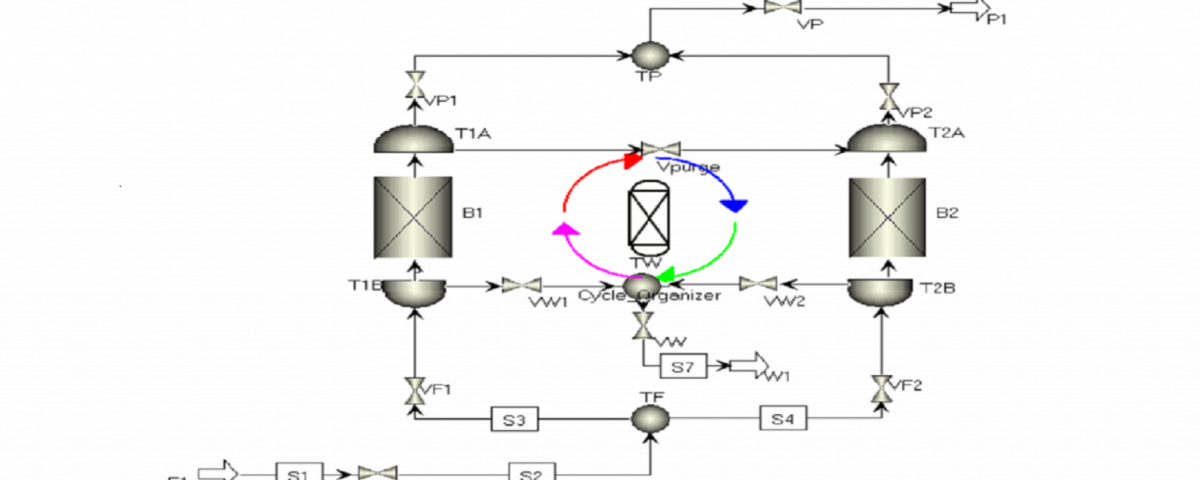

5. Nitrogen Gas Generator:

This device consists of two columns containing CMS (Carbon Molecular Sieve) absorbent material, piping and connections and all kinds of valves. Due to the difference in the molecular diameter of oxygen and the molecular diameter of nitrogen, only smaller oxygen molecules have the ability to penetrate into the micro carbon cavities in CMS absorbent materials. And these materials, based on the difference in molecular diameter, absorb oxygen molecules and air impurities. and allows nitrogen to leave the column. Finally, nitrogen is separated from the oxygen in the air with a purity higher than 95 to 99.9999%.

6. Nitrogen Storage:

Nitrogen production is collected in nitrogen collection capsules. In fact, the nitrogen storage tank provides a continuous and stable flow of high purity nitrogen.

In this project, the process of nitrogen separation from air is simulated in Aspen Adsim software.