Introduction

Liquefied Natural Gas (LNG) refers to natural gas that has been temporarily converted into a liquid state for the purpose of storage or transportation in significantly reduced volumes.LNG primarily consists of methane (over 90%) along with smaller quantities of ethane, propane, butane, and other heavier alkanes. Through the liquefaction process, it’s possible to produce LNG that is nearly 100% methane.

Compared to its gaseous state, LNG occupies only 1/600th of the volume. This liquid is colorless, odorless, non-toxic, and non-corrosive. However, it poses hazards such as flammability, cryogenic burns, and asphyxiation. LNG offers a significantly higher energy density, about 60% greater than diesel fuel.The liquefaction process involves removing impurities like dust, acid gases, helium, water, and heavy hydrocarbons, which can cause problems in pipelines.The purified natural gas is then cooled to -162°C at atmospheric pressure. For transportation purposes, the maximum pressure is typically limited to 25 kPa or 3.6 psi.

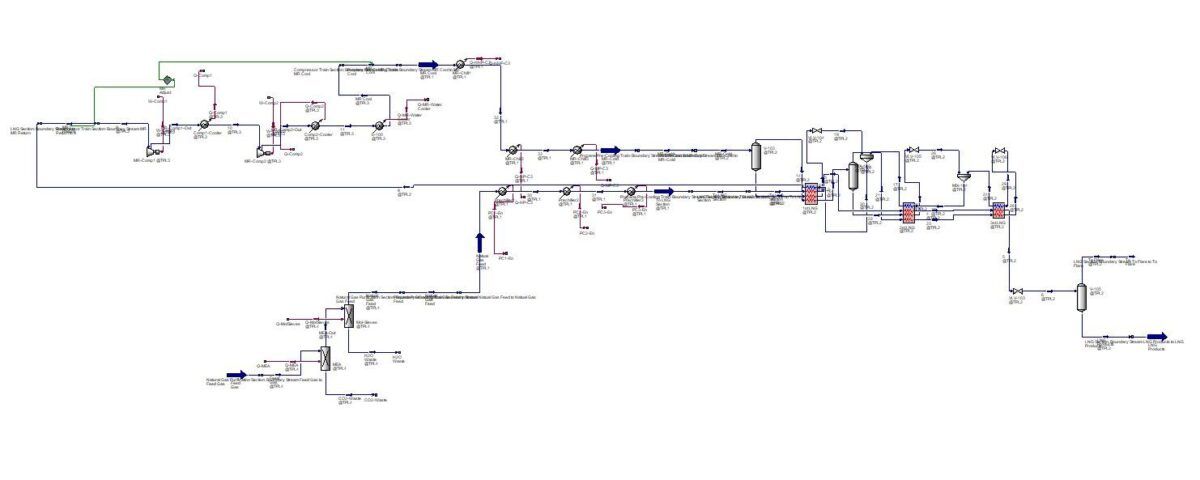

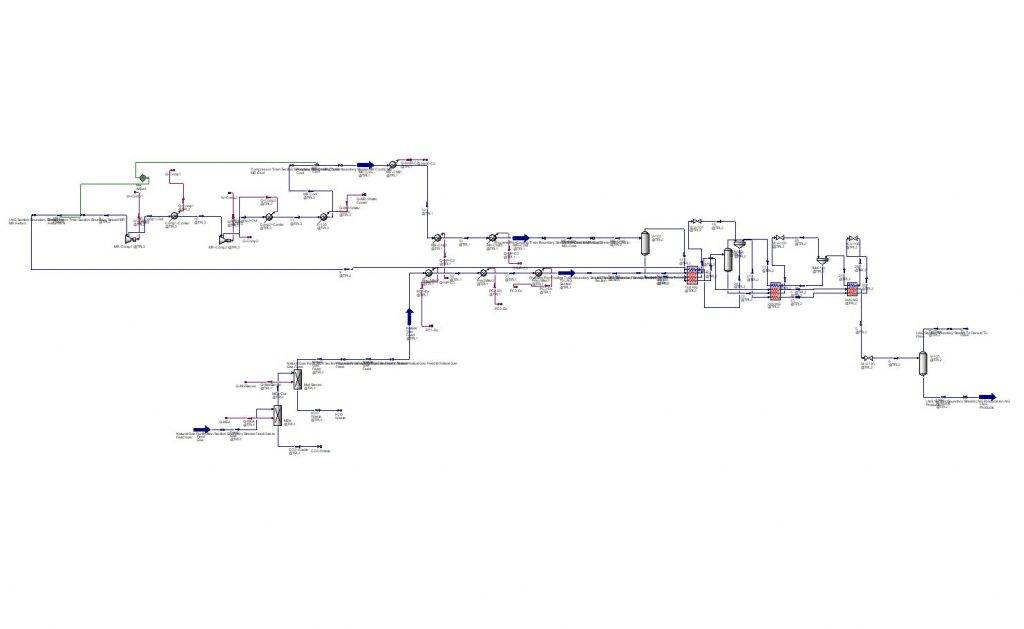

Simulating Liquefied Natural Gas (LNG) Production with Aspen Hysys

Liquefied Natural Gas (LNG) is natural gas that has been cooled to a very low temperature to convert it into a liquid state. This significantly reduces its volume, making it easier to transport.

The general steps in the LNG production process are:

1.Natural Gas Pre-treatment:

Removal of water and impurities: Raw natural gas contains impurities such as water, carbon dioxide, hydrogen sulfide, and heavier hydrocarbons. These impurities must be removed before liquefaction, as they can clog equipment and reduce process efficiency.

Removal of heavier hydrocarbons: Hydrocarbons heavier than methane (such as propane and butane) should also be removed from the gas, as they can liquefy at low temperatures and cause operational problems.

2.Compression:

The purified natural gas is compressed using multi-stage compressors. This increases the gas density and reduces its volume.

3.Refrigeration:

The compressed gas is cooled using heat exchangers and partial expansion. In this stage, the gas is gradually cooled until it reaches the boiling point of methane and liquefies.

4.Liquefaction:

At the lowest temperature point, the gas completely liquefies, and LNG is produced.

5.Storage:

Liquid LNG is stored in specially designed insulated tanks. These tanks are usually spherical or cylindrical and designed to maintain the low temperature of LNG.

This project is simulated with Aspen Hysys software.