Description

Today, the wide applications of hydrogen in the industry, especially its role as an energy carrier, have drawn the attention of researchers to this gas. More than 80% of today’s hydrogen production units use the method of changing the form of hydrocarbons. The gaseous mixture resulting from the process of changing the form of hydrocarbons is called synthesis gas. Along with hydrogen, it often contains impurities such as carbon dioxide, carbon monoxide, methane and nitrogen. Periodic pressure absorption is one of the most cost-effective methods of purifying hydrogen from this gas mixture on an industrial scale. However, operational costs and laboratory limitations of the periodic pressure absorption process have made the simulation of this process very important. In this project, we will simulate the hydrogen separation process in the TSA tower.

Temperature Swing Adsorption (TSA) Process

Advantages of the TSA Process

- High Selectivity: By selecting the appropriate adsorbent, hydrogen can be separated from gas mixtures with very high purity.

- Versatility: The TSA process can be used to separate a wide range of gases.

- Relative Simplicity: The equipment used in this process is relatively simple and cost-effective.

- Environmentally Friendly: This process is environmentally friendly and does not use harmful chemicals.

Applications of the TSA Process

- Hydrogen Separation: The primary application of TSA is the separation of hydrogen from gas mixtures such as synthesis gas.

- Noble Gas Separation: Separation of noble gases like helium and neon from air.

- Gas Drying: Removal of moisture from gases.

- Industrial Gas Purification: Removal of impurities from industrial gases.

Factors Affecting TSA Performance

- Adsorbent Type: The selection of the appropriate adsorbent for each specific gas is crucial.

- Temperature: Adsorption and desorption temperatures significantly impact the amount of gas adsorbed and desorbed.

- Pressure: Pressure also affects the amount of gas adsorbed.

- Gas Flow Rate: The gas flow rate influences the contact time between the gas and the adsorbent, thus affecting process efficiency.

Pressure Oscillation Surface Absorption (PSA) Method

Principles of Pressure Swing Adsorption (PSA)

In the Pressure Swing Adsorption (PSA) process, the adsorption properties of solid materials (adsorbents) are utilized to separate different components of a gas mixture under pressure. The main steps of this process are as follows:

- Adsorption: The gas mixture is introduced into a bed filled with adsorbent under high pressure. At high pressure, gas molecules adhere to the adsorbent surface and are adsorbed. The amount of adsorption of each gas depends on the type of gas and pressure.

- Desorption: After the adsorbent becomes saturated, the pressure is reduced. With decreasing pressure, the bonds between gas molecules and the adsorbent weaken, and the adsorbed gases are desorbed from the adsorbent surface and collected as pure or high-purity gas.

- Regeneration: After gas desorption, the adsorbent is prepared for the next adsorption cycle. This is usually done by reducing the pressure and passing an inert gas through the bed.

The Difference Between PSA and TSA

PSA is widely used for gas separation. In gas drying by adsorption, PSA refers to the process of adsorption at higher pressure and desorption at reduced pressure. Desorption is generally carried out at atmospheric pressure. Some utilize vacuum to reduce pressure. Simply put, the desiccant that has adsorbed water under high pressure is desorbed by reducing the pressure to atmospheric. After pressure reduction, it should be transferred into the tower.

The regenerated gas with lower relative humidity, even if the partial pressure of water vapor in the regenerated gas is lower than the equilibrium vapor pressure at the surface of the desiccant, desorption can be completed. Therefore, PSA utilizes the principle that when desorption is carried out under reduced pressure, the partial pressure of water vapor decreases, and the adsorption capacity decreases.

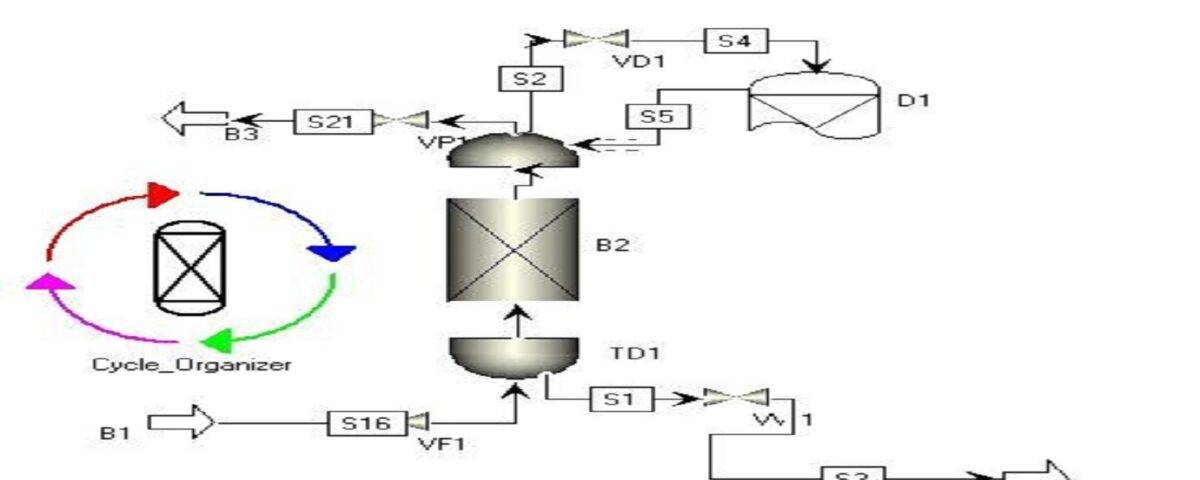

Simulation of Hydrogen Separation Process in TSA Tower

This project presents a simulation of hydrogen separation in a Temperature Swing Adsorption (TSA) tower using Aspen Adsim software. The project includes an instructional video.