Description

Today, the wide applications of hydrogen in the industry, especially its role as an energy carrier, have drawn the attention of researchers to this gas. More than 80% of today’s hydrogen production units use the method of changing the form of hydrocarbons. The gaseous mixture resulting from the process of changing the form of hydrocarbons is called synthesis gas. Along with hydrogen, it often contains impurities such as carbon dioxide, carbon monoxide, methane and nitrogen.

Periodic pressure adsorption is one of the most cost-effective methods of purifying hydrogen from this gas mixture on an industrial scale. However, operational costs and laboratory limitations of the periodic pressure absorption process have made the simulation of this process very important. In this project, we will simulate the hydrogen separation process in the TSA tower.

TSA Process

Adsorption with alternating temperature changes or TSA is one of the most common surface adsorption separation methods. Surface absorption is an exothermic process, and therefore, with increasing temperature, the amount of absorption decreases. In the TSA method, the temperature is lowered in the adsorption phase and increased in the repulsion phase.

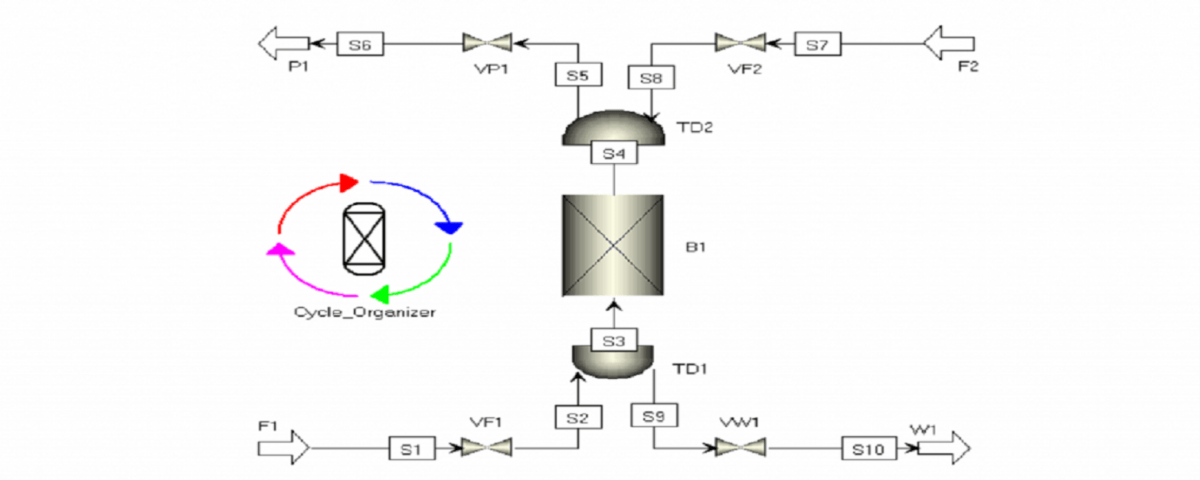

The regeneration step is usually done by passing a part of the gas product flow that has the ability to clean the bed, or another gas that has a negligible amount of absorption in the bed. The regeneration flow is preheated before entering the bed and then enters the bed. Usually, by performing regeneration operations at high temperature, the bed is well cleaned and can be ready to enter the next cycle. The figure below shows the hydrogen separation unit in TSA towers.

Simulation of H2 Separation Process in TSA Tower in Aspen Adsim

In this project, the hydrogen separation process in the alternating temperature tower is simulated with the help of Aspen Adsim software. Also, this project has an educational video.