Description

Natural gas extracted from gas reservoirs mainly contains a significant amount of gas condensate. Especially when the volume of gas withdrawal from the tank is large. Gas condensate is a liquid hydrocarbon stream that exists in natural gas deposits and is found as sediment in extracted gas and is mainly composed of pentane and heavier hydrocarbons (+C5) and has low sulfur and usually It is free from all kinds of metals and almost half of it is naphtha.

Gas condensate, unlike butane and propane, does not require special conditions to remain liquid. They are able to convert into light oil, gasoline, jet fuel, etc. in different ways. In comparison with the crude oil refinery, the conversion and refining processes are less in the gas condensate refinery. Therefore, its investment cost is half of the investment cost of a crude oil refinery.

Simulation of The Gas Condensate Stabilization Unit in The Catalytic Conversion Section of Isfahan Refinery

This research was done with the aim of getting familiar with Isfahan refinery and catalytic conversion unit and the operations that can be done to create optimal conditions for extracting gasoline in this unit. Isfahan Refinery provides the basis for crude oil refining and production of various products such as gasoline, heating oil, aviation fuel. The design of this refinery is completely similar to two refineries. The liquefied gas production unit and stabilizing unit from area A and catalytic conversion unit from area B have been investigated.

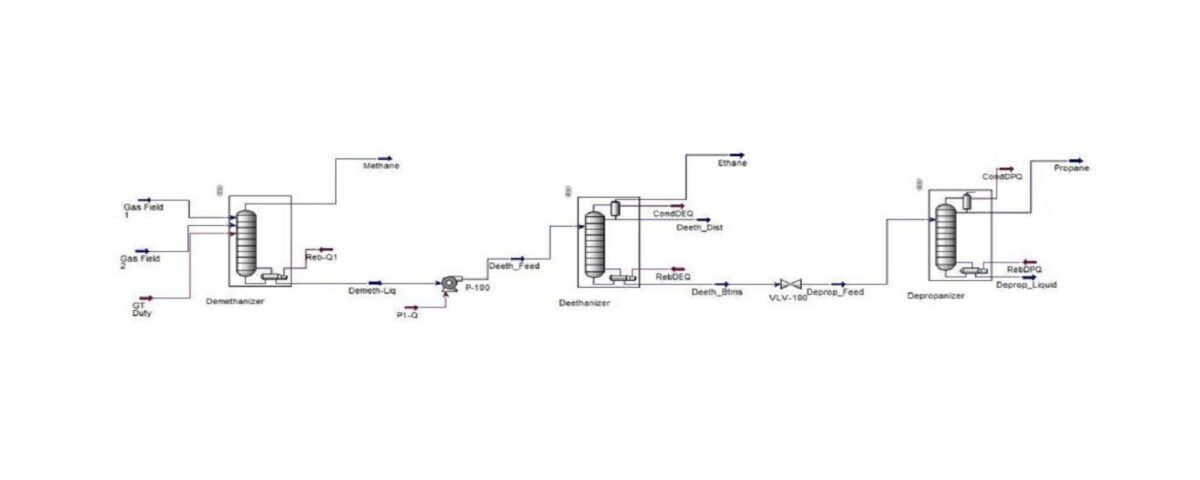

Condensate stabilization unit has six separate parts including medium pressure separator, stabilization tower feed container, gas condensate filter, gas condensate stabilization tower, gas condensate cooler and final gas condensate cooler. Condensate stabilization tower reduces the vapor pressure of condensate by removing light components. HYSYS software is one of the most popular software in the field of chemical engineering, in line with this research, the simulation of the gas condensate stabilization tower was evaluated with the help of the software, and the simplified form of the gas condensate stabilization unit was simulated in steady state.

This project has been done using the data of the following article with the help of Aspen Hysys software.

Conclusion

Simulation of the gas condensate stabilization unit in the catalytic conversion section of Isfahan Refinery. It acts as a vital tool in optimizing performance and increasing production efficiency. and using simulation software. It provides the possibility to analyze the behavior of processes. This simulation not only helps to identify the optimal operating conditions including temperature, pressure, etc. Rather, it brings significant economic benefits by reducing production costs and improving the quality of final products. Overall, simulation is a key tool in the refinery industry, helping to improve resource performance and sustainability. And it plays an important role in responding to the evolution of catalytic technologies.