Introduction

Diethyl ether is a highly volatile, neutral, and flammable liquid with a distinct odor. This liquid is miscible with most organic solvents in all proportions. Diethyl ether serves as an excellent solvent for oils, fats, resins, fragrances, and several other organic compounds. It is produced through the dehydration of alcohol using an acidic catalyst. The simulation of diethyl ether from ethanol is an important process in the chemical industry aimed at producing clean and sustainable fuels. Diethyl ether, as a biofuel and solvent with desirable properties, has numerous applications in various industries.

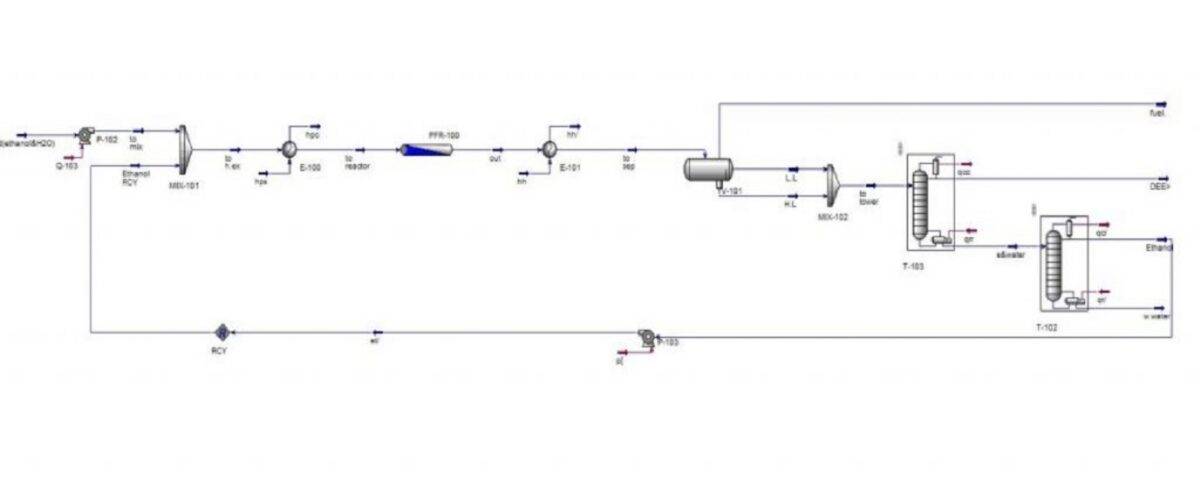

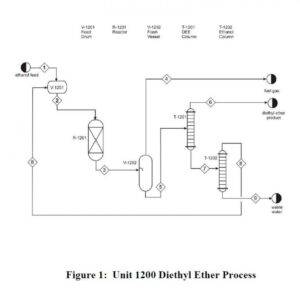

The use of Aspen HYSYS software in this area allows engineers and researchers to accurately model chemical processes, predict unit performances, and carry out necessary optimizations. This simulation involves various parameters such as temperature, pressure, and the composition of feed materials, which can aid in the design and improvement of the diethyl ether production process.

In this project, the process of producing diethyl ether from ethanol has been simulated using Aspen HYSYS based on a reference article.

This project is conducted based on an article and does not include a report.

Process Description

The process of producing diethyl ether from ethanol typically involves simultaneous reactions under high temperature and pressure, where ethanol is converted into diethyl ether and water with the help of catalysts such as strong acids. This process is usually carried out in a chemical reactor, where ethanol is initially vaporized into gas and then comes into contact with a catalyst at the appropriate temperature and pressure.

The main reaction involves the removal of water molecules from ethanol, resulting in the production of diethyl ether. After the reaction is complete, the products are transferred to a separation system where diethyl ether is effectively separated from water and other by-products. These separated components are then purified using distillation or absorption methods to obtain high-quality diethyl ether. This process not only optimizes energy efficiency but also reduces the environmental impacts associated with fossil fuel production.

Conclusion

The simulation of the diethyl ether production process from ethanol using Aspen HYSYS is an effective tool for optimizing and analyzing the performance of this chemical process. This simulation helps engineers thoroughly examine the factors influencing the reaction, ideal operational conditions, and separation stages.