Introduction

Ethanol is a potential energy source to replace dwindling petroleum reserves. Lignocellulosic materials are used to produce ethanol, and the primary process involved in converting these materials into bioethanol consists of two main stages: the hydrolysis of cellulose present in lignocellulosic materials to produce sugars and the fermentation of the resulting sugars into ethanol. Cellulose and similar polysaccharides are the most abundant organic compounds on Earth and are found in plant structures. Plant biomass is primarily composed of three compounds: cellulose, hemicellulose, and lignin. If, through a suitable and economical process, plant cellulose can be converted into simple, fermentable sugars, it will revolutionize the food industry and the production of natural fuels.

After the production of glucose, using other microbes and the fermentation process, ethanol can be produced from the existing sugars, serving as a suitable substitute for fossil fuels. The breakdown of cellulose and its conversion into glucose can be achieved by microorganisms possessing the enzyme cellulase. Cellulase production is the most expensive part of the alcohol production process, accounting for approximately 25-40% of the total cost. Therefore, extensive research is underway to reduce the cost of enzyme production.

Bioethanol Production

Bioethanol is a rich source of clean fuel, serving as an alternative to fossil fuels. It also finds widespread use in lower concentrations for hygienic and medical purposes. Lignocellulosic materials are used for ethanol production. The cellulosic components of agricultural residues like bagasse and molasses contain significant amounts of lignocellulose. Moreover, bagasse and molasses possess hydrocarbon compounds, making them excellent feedstocks for bioethanol production , Producing bioethanol from lignocellulosic materials requires in-depth engineering knowledge, statistical estimations of required hydrocarbon consumption, and precise engineering calculations for adding other necessary compounds during the various production stages to achieve a specific ethanol purity percentage.

Many raw materials used in ethanol production through fermentation are categorized into three types of agricultural raw materials: sugars, starch, and cellulose. Sugars (sugarcane, sugar beet, molasses, and fruits) can be directly converted to ethanol. Starches (grains, potatoes, root crops) must first be hydrolyzed into fermentable sugars using enzymes from malt or molds. Cellulose (wood, agricultural residues, sulfite liquor from paper mills, and paper pulp) must be converted into sugars using mineral acids. Once simple sugars are formed, yeast enzymes can easily ferment them into ethanol. Molasses, a byproduct of the sugar industry, is a promising raw material for ethanol production.

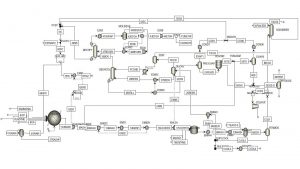

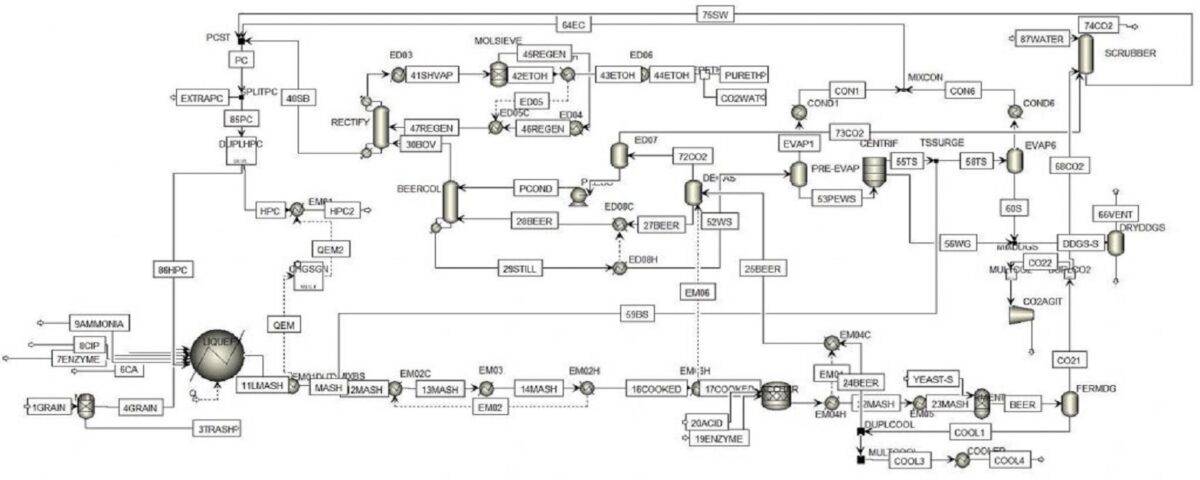

Bioethanol Production Simulation

In this project, the bioethanol conceptual unit is simulated with Aspen Plus software. An overview of the simulation is available in the figure below.