Introduction

Due to the excessive consumption of fossil fuels in developing countries, significant efforts have been made to find a suitable alternative fuel for current energy and transportation systems. Biodiesel is one of the promising options.

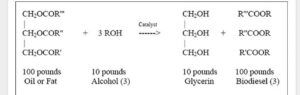

Biodiesel is a renewable fuel that is widely used in today’s life. However, since this fuel is finite and causes air pollution, there is a need to replace it with a renewable and clean fuel. One such fuel is biodiesel, which is a clean fuel produced from renewable sources. There are various methods for producing biodiesel, with transesterification being the most common method. It involves the reaction of oil with alcohol and a catalyst. The type of alcohol used in this process can be methanol or ethanol.

Various catalysts, including acidic, basic, and nanocatalysts, are used. In this study, biodiesel production methods including pyrolysis, microemulsion, and transesterification are presented. Also, a comparison of homogeneous and heterogeneous acid catalysts, homogeneous and heterogeneous basic catalysts, and nanocatalysts along with their advantages and disadvantages is discussed. Nowadays, heterogeneous and nanocatalysts are more favored.

The reactions involved in biodiesel production are as follows:

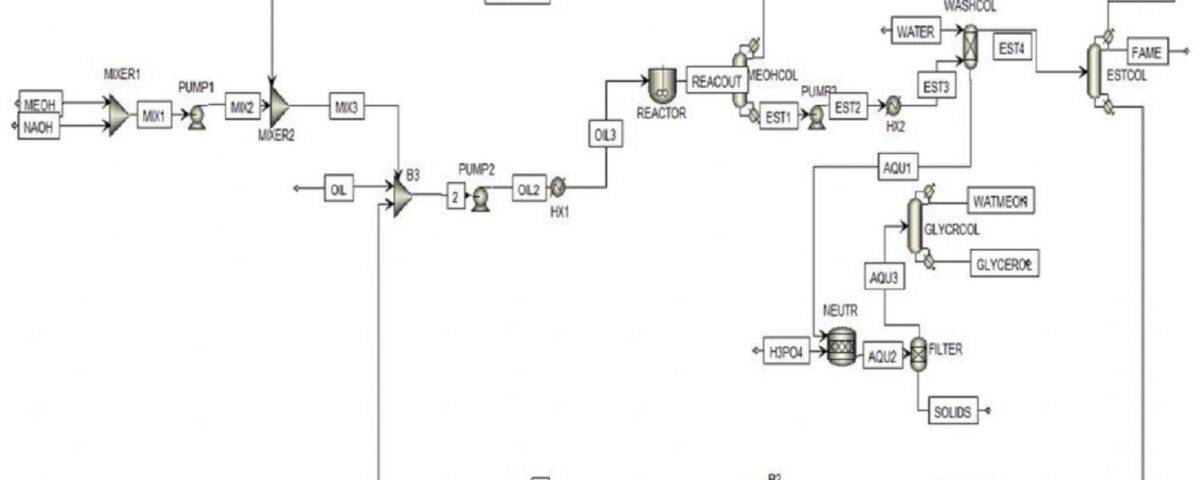

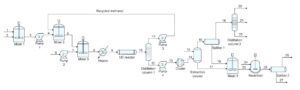

In this project, the production of biodiesel from canola oil is simulated with Aspen Plus software. The reference for this project is the following article.

Click on the link below to download the article.

Techno-economic assessment of biodiesel production from canola oil through ultrasonic cavitation

The figure below shows the general outline of the simulated process.

This project was conducted in Aspen Plus based on the mentioned article.