Introduction

A gas refinery is a processing unit designed to process, prepare, and optimize the properties of natural gas extracted from gas wells. In a gas refinery, compounds that reduce the heating value of the gas and create issues in transportation and consumption are separated from natural gas and subsequently delivered to transportation lines. ASPEN HYSYS simulation serves as a powerful tool in modeling industrial processes, particularly in the context of gas refineries.

In this respect, simulating the initial water removal unit of gas refinery feed is essential for optimizing performance and increasing the overall efficiency of the system. This unit plays a crucial role in the refining process, effectively removing water, acidic gases, and other contaminants from the gas feed. By utilizing ASPEN HYSYS software, engineers can analyze and optimize operational parameters, reduce costs, and enhance the quality of the final product. This simulation not only aids in better understanding the system’s behavior but also allows for the prediction and optimal management of process variations.

Gas Reception and Natural Gas Liquids Separation Unit

The gas reception and natural gas liquids separation unit in gas refineries serves as the initial stage in the refining process, playing a vital role in ensuring the quality and purity of the produced gas. In this unit, gas feed from various sources enters a separation system. Initially, the raw gas is liquefied under pressure and temperature conditions to separate unwanted solid particles and liquids.

During this stage, using separation equipment such as horizontal and vertical separators, natural gas liquids are extracted from the gas. These liquids consist of high molecular weight hydrocarbon compounds, which are typically used as fuels and raw materials for the production of other chemical processes. The separated gas is then sent to subsequent refining units, while the liquids are collected for storage or further processing.

Process Description

The initial water removal process in gas refineries, aimed at eliminating water and other contaminants from gas feed, encompasses several key stages designed as a system comprising various equipment. This process typically begins with the entry of gas feed into a separation system, where gas is separated from liquids under the influence of gravity and pressure. Following this stage, the purified gas enters an absorption unit, where water vapor and acidic gases such as carbon dioxide and hydrogen sulfide are removed using specific absorbents or solvents.

At this stage, methods such as physical or chemical absorption are commonly employed. The cleaned gas is then transferred to a compressor to increase its pressure and prepare it for the next processing stage. These objectives can be achieved through the simulation and optimization of various parameters in software such as ASPEN HYSYS.

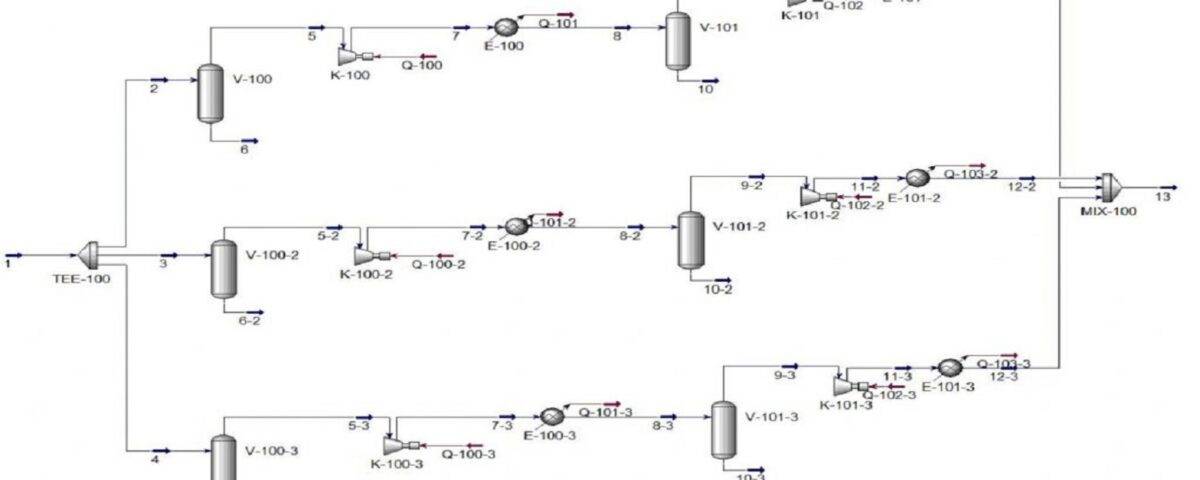

Simulation of the Initial Water Removal Unit of Gas Refinery Feed

In this project, the initial water removal unit of gas refinery feed has been simulated using ASPEN HYSYS software. This unit represents the first stage following the entry of gas from storage into the gas refinery.