Introduction

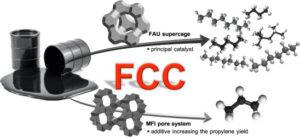

Fluid Catalytic Cracking (FCC) is considered one of the most important catalytic conversion units and processes in the world, transforming heavy and low-value petroleum materials into lighter and more valuable products. With the increasing global demand for fuel and the need to convert heavy materials into lighter fuel products, the significance of this process has grown tremendously.

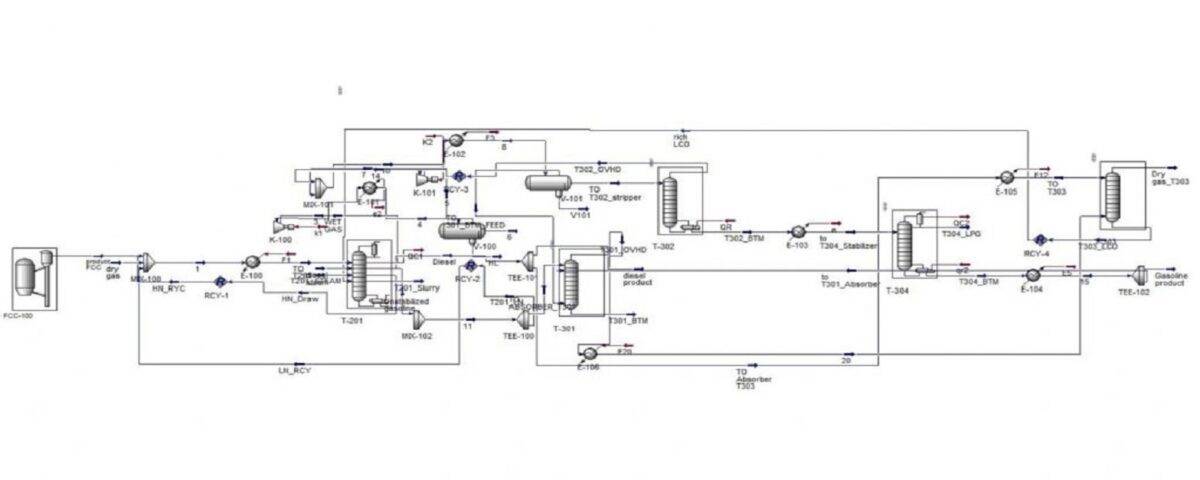

The simulation of Aspen HYSYS for the Fluidized Catalytic Cracking (FCC) unit serves as a critical tool in optimizing petrochemical processes and oil refining. This technology plays a key role in the energy industries due to its ability to convert heavy petroleum materials into more valuable products, including gasoline and diesel. In this context, accurate simulation can enhance the understanding of flow dynamics, heat transfer, and chemical reactions within the catalytic bed. By utilizing advanced computational models and numerical methods, one can analyze the behavior of catalysts and the effects of various operational conditions on unit performance.

Since the establishment of the first commercial FCC unit, this technology has been widely adopted as the most common method for cracking heavy petroleum molecules and producing valuable products in refineries around the world.

Fluidized Catalytic Cracking Unit (FCC)

In this process, heavy cuts are converted into lighter products and coke in the presence of a catalyst. In the FCC process, in addition to gasoline, other products such as light gases (methane and ethane) and compounds heavier than the feedstock are generated. The yield of each of these products depends to some extent on the operational conditions, particularly the conversion rate of the feed. If the unit operates at low conversion rates, its primary product is diesel fuel; at medium conversion rates, gasoline becomes the main product; and at high conversion rates, light olefin gases are the primary yield.

Process Description

The Fluid Catalytic Cracking (FCC) process is an advanced method for converting heavy petroleum materials into more valuable products, including gasoline, diesel, and petrochemicals. This process is conducted in two main sections: the reaction unit and the separation unit.

In the first stage, the oil feedstock is subjected to appropriate heating and begins the decomposition into lighter molecules, relying on a liquid catalytic bed. Here, the catalytic fluid is continuously circulated, and the catalytic particles move freely within the bed, enhancing the contact surface between the feed and the catalyst, thus increasing the rate of reactions.

Following this stage, the products generated from the reaction are directed towards the separation unit. In this unit, the separation of products is carried out based on their physical characteristics, including boiling points. This method allows for effective and precise separation of various products and aids in optimizing the extraction process.

The results of this process can be influenced by various operational conditions such as temperature, pressure, and the type of catalyst used. Optimizing these parameters can significantly enhance the performance and quality of the final products. Additionally, this process is economically and environmentally significant due to the recycling of the catalyst and its re-use.

Conclusion

Overall, the simulation of the Fluid Catalytic Cracking (FCC) process serves as a crucial tool in optimizing and managing petrochemical units. These simulations provide detailed insights into the dynamic and chemical behaviors of the system, contributing to improved process efficiency, reduced operational costs, and enhanced quality of the final products. By employing advanced computational models, more accurate predictions of reactions and catalyst performances can be achieved, leading to the design and implementation of optimized processes.

Furthermore, given the environmental and economic challenges in the oil and gas industry, FCC simulation offers a sustainable and efficient solution for waste reduction and energy consumption optimization. Ultimately, ongoing research and development of technologies related to the simulation of this process can lead to innovative and sustainable solutions in the petrochemical industry.

Simulation of Fluid Catalytic Cracking Unit (FCC)

In this project, the Fluid Catalytic Cracking (FCC) unit has been analyzed using Aspen HYSYS software. The simulation is based on related literature.