Introduction

The increasing global demand for natural gas necessitates not only the improvement of existing processes for energy production and consumption but also effective pollution control. One of the most significant challenges faced by technologies related to natural gas processing is the presence of high amounts of acid gases, which account for approximately 40% of the gas output from wells. About 13.46% of natural gas reservoirs worldwide contain H2S levels exceeding 10%, while around 26.9% of these reservoirs have CO2 concentrations greater than 10%. This project focuses on the simulation of carbon dioxide absorption from natural gas using Sulfinol-M.

Sweetening Natural Gas

In the 1930s, alkanolamines were first used for sweetening gas, and until the 1970s, monoethanolamine (MEA) was the most widely used. However, due to the drawbacks of MEA, such as corrosion and solvent loss, diethanolamine (DEA) replaced it after the 1970s. Since the mid-1970s, particularly in the last two decades, methyl diethanolamine (MDEA) has gained extensive application in the gas industry due to its advantages, such as selective separation of hydrogen sulfide in the presence of carbon dioxide, high stability, and low energy consumption for solvent recovery.

Alkanolamines generally consist of at least one hydroxyl group (-COH) and at least one amino group (-NH2). The commonly used amines for gas sweetening include:

– Primary amines: Monoethanolamine (MEA) and diglycolamine (DGA)

– Secondary amines: Diethanolamine (DEA) and diisopropanolamine (DIPA)

– Tertiary amines: Triethanolamine (TEA) and methyl diethanolamine (MDEA)

Sulfinol-M Solvent

Sulfinol-M is composed of a mixture of sulfolane (a physical solvent), methyl diethanolamine (MDEA), and water. The ratio of sulfolane, MDEA, and water in the solvent varies according to the characteristics of the feedstock and the quality of the treated gas. In the Sulfinol-M process, the amount of sulfolane can be increased while reducing the ratio of MDEA. It is noteworthy that sulfolane can be used at concentrations greater than 40%. Ultimately, the concentration of sulfolane in this process depends on parameters such as sweet gas quality, investment costs in various sectors including energy, solvents, and other operational conditions.

Process Description

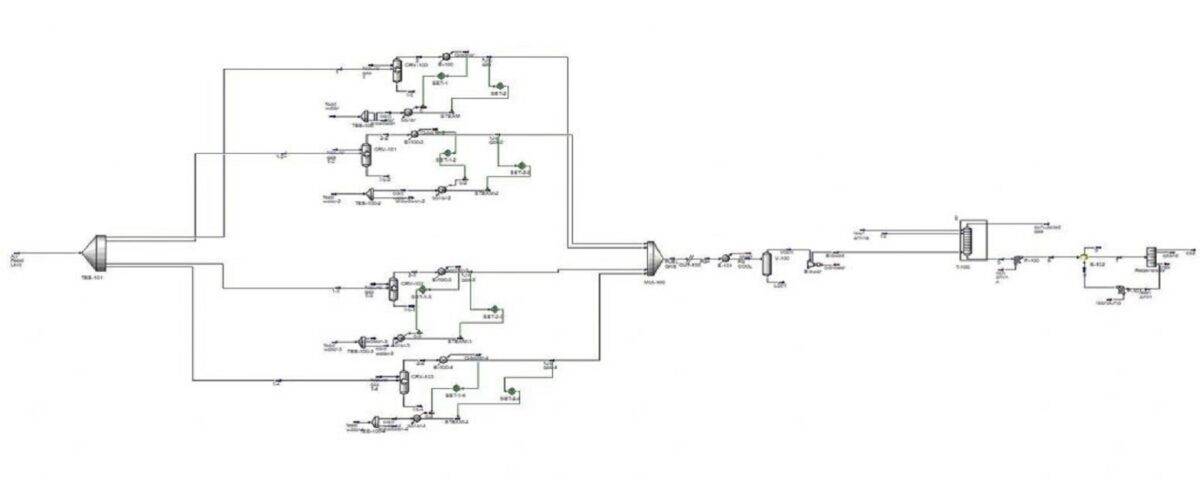

The simulation of the carbon dioxide absorption process from natural gas using Sulfinol-M aims to optimize performance and enhance the efficiency of the process. Initially, operational conditions, including temperature, pressure, and concentrations of natural gas and CO2, are established. Subsequently, a mathematical model of the absorption process is created using equations related to mass transfer and phase equilibrium. Sulfinol-M acts as a multi-functional solvent, improving the capability to absorb CO2. The simulation can be performed using chemical simulation software like Aspen HYSYS, which assists in analyzing operating points, temperature and pressure changes, and CO2 absorption levels. The results of the simulation can aid in evaluating various effects on absorption efficiency and designing optimized industrial systems for reducing carbon dioxide emissions.

Conclusion

The conclusion of the simulation of the carbon dioxide absorption process from natural gas using Sulfinol-M indicates that this solvent serves as an effective option for reducing CO2 concentrations in gas sources. The evaluations conducted suggest that by optimally adjusting operational conditions, absorption efficiency can be significantly increased, thereby reducing the costs associated with natural gas treatment. Furthermore, these simulations highlight the positive environmental impacts of this process, as reducing CO2 emissions can play an important role in addressing climate change. Overall, the results of this study could pave the way for the design of optimized industrial systems for carbon dioxide absorption and enhancing energy sustainability.

Simulation of Carbon Dioxide Absorption from Natural Gas with Sulfinol-M

In this project, the process of carbon dioxide absorption from natural gas using Sulfinol-M has been simulated in Aspen HYSYS software.