Description

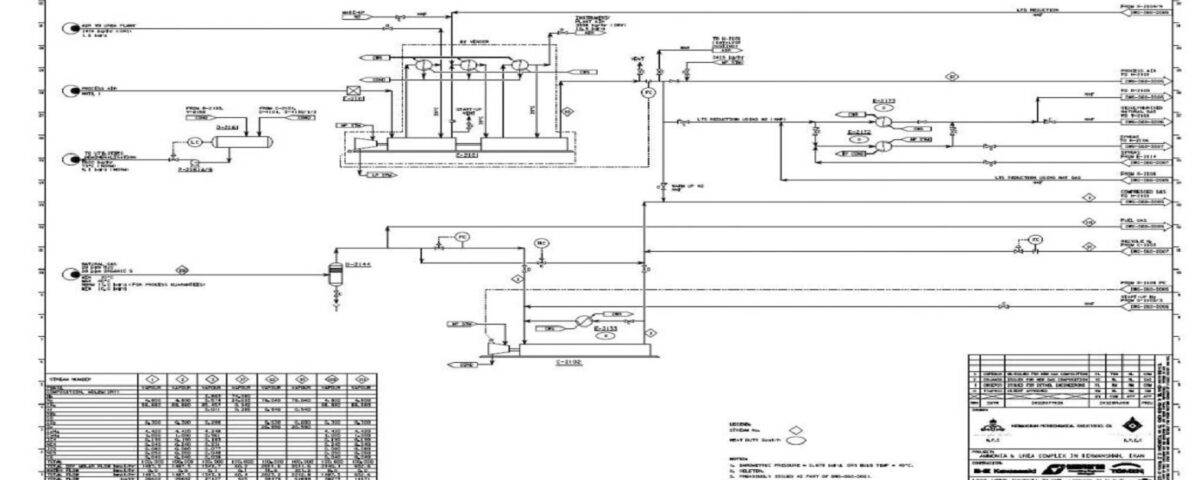

The design of the Kermanshah Petrochemical Ammonia Unit is based on reducing the energy of the ammonia process, under the technical knowledge (license) of Kellogg UK. This unit is designed to produce 1200 tons per day of ammonia and 1494 tons per day of carbon dioxide with natural gas input. In normal operation, most of the produced ammonia is sent to the urea unit as a hot liquid at a temperature of 37 degrees Celsius, and the remainder is sent to the storage tank as a cold liquid at minus 35 degrees. This unit also has the ability to send 1200 tons per day of produced ammonia as cold liquid to the storage tank.

About 60% capacity reduction is considered for this design. The unit operates at 40% of its capacity for a period with special restrictions (less than 7 days) with no special design anticipated, but may require additional operational considerations and considerations.

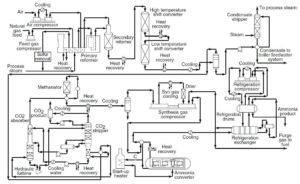

The Process Consists of The Following Parts:

Preparation of primary and raw synthesis gas

Synthesis gas purification

Purified synthesis gas condensation and ammonia synthesis

Ammonia refrigeration system

Disposal of process condensate

Other process equipment and facilities

steam

Cooling water

Open burner and vent system

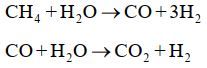

Reforming Reaction of Water Vapor and Methane

Ammonia Production Reaction

![]()

The simulation of ammonia production and reforming process has been done in Aspen Plus software. It should be noted that the error of simulation done with industrial data is less than 10%.

Files in the project:

Full description of the process

PFD industrial diagram

Complete kinetics of the reactions in the synthesis reactor

Concept diagram

Aspen Plus simulation