Introduction

Liquid gas (LPG) is mainly made of propane and butane. Butane has two forms: isobutane and normal butane. LPG has the lowest greenhouse gas emissions compared to other fuels. It’s a byproduct of natural gas and crude oil refining. LPG is colorless, odorless, and tasteless. It’s generally safe, but inhaling a lot can cause anesthesia. To detect leaks, sulfur compounds called mercaptans are added to LPG.

Description of the process

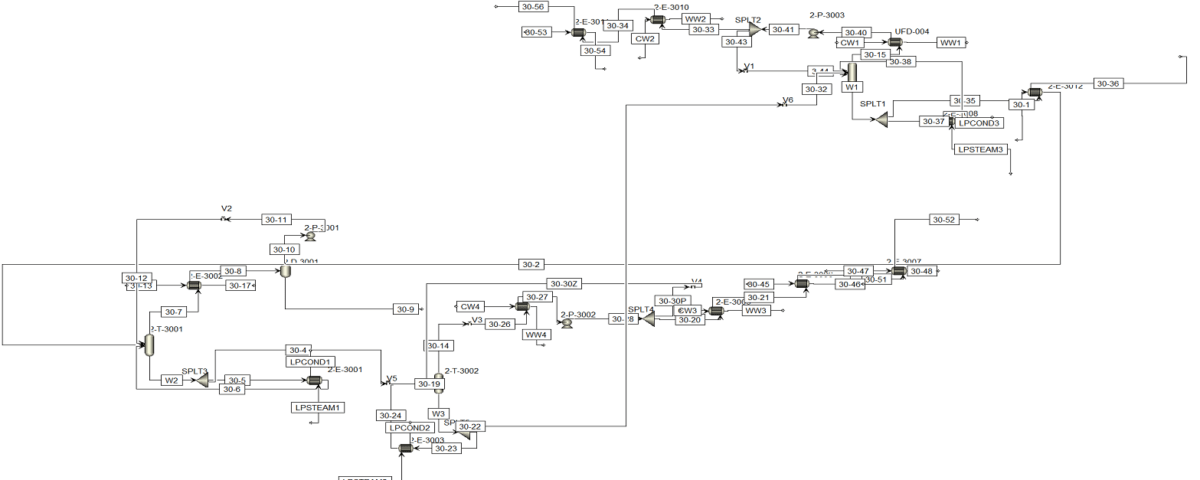

To simulate the LPG (Liquid Petroleum Gas) unit using Aspen Plus software, we will go through different steps. This unit separates LPG from the feedstock, which is usually a mixture of light hydrocarbons such as propane, butane and other components. The steps include defining the system components, choosing the method of thermodynamic properties, creating a process flow chart including the distillation column, heat exchanger, compressor or pump, and heat exchanger regenerating and condensing, defining the feed flow, setting the distillation column, running the simulation, analyzing the results including temperature profiles and The pressure and combination of products at the top and bottom of the column and finally optimization and sensitivity analysis to improve the efficiency and purity of LPG.

conclusion

Regarding the simulation of the LPG unit, Aspen Hysys software provides the possibility of accurate modeling of various equipment, including distillation towers, absorbers and heat exchangers, and helps process engineers to gain a deeper understanding of the operation of these units.

Simulation of LPG unit with Aspen Plus

In this project, LPG unit simulation is simulated in Span Plus software.