Description

In the petrochemical industry, creative designs and process development methods should be considered with the aim of reducing the size of equipment, consuming less raw materials and energy, and producing minimal waste. Also, currently Iran and the world are at a certain point in time in terms of optimizing the processes of using energy resources. Preventing the wastage of these resources and preserving them for future generations and providing new sources of affordable and clean energy. One of the most effective methods to achieve these goals is the use of modern membrane processes. Usually, one of the most expensive steps in the chemical and petrochemical industries is separation. Membrane processes have many advantages over many conventional separation methods (such as distillation, extraction, and adsorption).

In membrane processes, no phase changes occur, which usually require a lot of energy, expensive absorbents are not used. Also, there is no need to use solvents that are not easy to work with. Meanwhile, these processes are very compact and easily scalable, fully automatic and do not have any moving parts. In this regard and considering the importance of separation processes using membrane methods and the country’s need to use this technology and strategy, as well as the existing problems in the field of providing these technologies from abroad, one of the main and long-term goals is to achieve the technology The manufacturing of different types of membranes, the technologies related to modulating these membranes and the development of different membrane processes were and are in the country.

Membrane Technology

Today, membrane technology has found a special place in various industries due to its many advantages compared to other separation technologies. The increasing use of this technology in various industries, especially the oil, gas and petrochemical industries, is a proof of this claim.

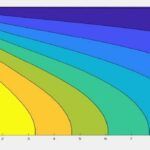

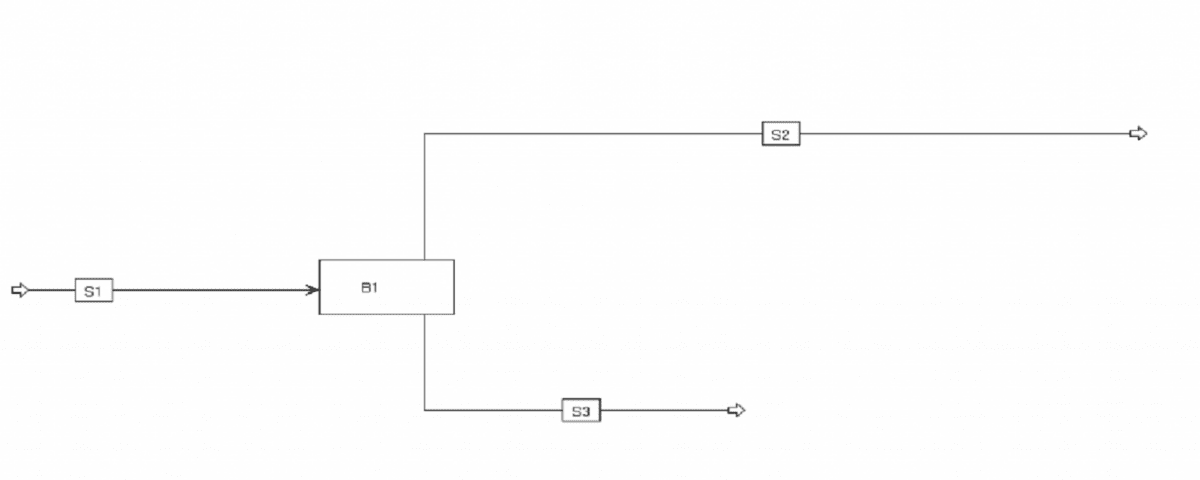

To remove industrial gases, equipment such as packed towers, spray towers, scrubber cleaners and bubble columns are used. In this equipment, by dispersing the gas phase in a liquid phase, the contact surface and as a result the mass transfer rate increases. Although these methods are very common, there is no accurate estimation of mass transfer level in them. Due to process limitations in liquid and gas speed, non-porous polymer membranes are usually used to separate gases. The use of solid membranes for gas removal is limited due to low separation coefficient and low permeability. To solve this problem, membranes with high selectivity and higher thermal resistance have been developed. The figure below shows a unit for separating carbon dioxide from natural gas.

CO2 Separation Using Membrane

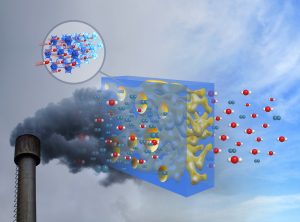

The first theory about carbon dioxide and its environmental effects by T.C. Chamberlain was introduced in the late 19th century. According to his theory, the change in the amount of atmospheric carbon dioxide has a great effect on the vast climate changes. And industrial activities are the main responsible for increasing the amount of carbon dioxide in the atmosphere. Studies conducted in our country include 75% of greenhouse gases, indicating that carbon dioxide will be around 80%.

Therefore, carbon dioxide can be considered as the most important greenhouse gas, and for this reason, scientists and environmental experts believe that if the release of carbon dioxide into the atmosphere is prevented, the environmental effects of greenhouse gases can be significantly reduced. CO2 separation by membrane in comparison with adsorption or distillation processes while having easier operation and lower cost compared to other physical separation processes, has less energy consumption and is suitable for separation processes in small to medium separation scales. Among the existing techniques, the membrane process is a relatively new technology that is used to absorb CO2 from natural gas.

Simulation of CO2 Separation with Membrane in ACM and MATLAB

In recent decades, membrane performance has been described by various mathematical models, but less work has been done regarding the process simulation of membrane models by existing simulators. In this project, the simulation of carbon dioxide separation using membrane has been done in Aspen Custom Modeler (ACM) software. Also, this project has a coding file in MATLAB software, a report and an educational video.