Introduction

Biodiesel is a type of fuel produced from the processing and modification of vegetable oils. It was first introduced in the 1970s as an alternative to petroleum diesel, but it did not gain much popularity at that time. Today, with the decline of oil resources and the increasing demand for various fuels, the production and use of biodiesel have become significant and important.

The molecular sizes in biodiesel and petroleum diesel are similar; however, these two fuels differ in their chemical structures. Biodiesel molecules are almost entirely composed of methyl esters of fatty acids, which contain unsaturated aliphatic compounds. In contrast, 95 percent of petroleum diesel (with low sulfur content) consists of saturated hydrocarbons, with the remaining 5 percent made up of aromatic compounds. If ethanol is used instead of methanol in the production of biodiesel, the resulting molecules will be ethyl esters of fatty acids.

Biodiesel Production Process

Biodiesel can be produced from vegetable oils, yellow grease, cooking oils, or animal fats. This is accomplished through a process called transesterification, which produces biodiesel and glycerin as products. Approximately 100 weight parts of oil or fat react with 10 parts of a short-chain alcohol (usually methanol) in the presence of a catalyst (commonly sodium hydroxide or potassium hydroxide) to ultimately form 100 parts of biodiesel and 10 parts of glycerin.

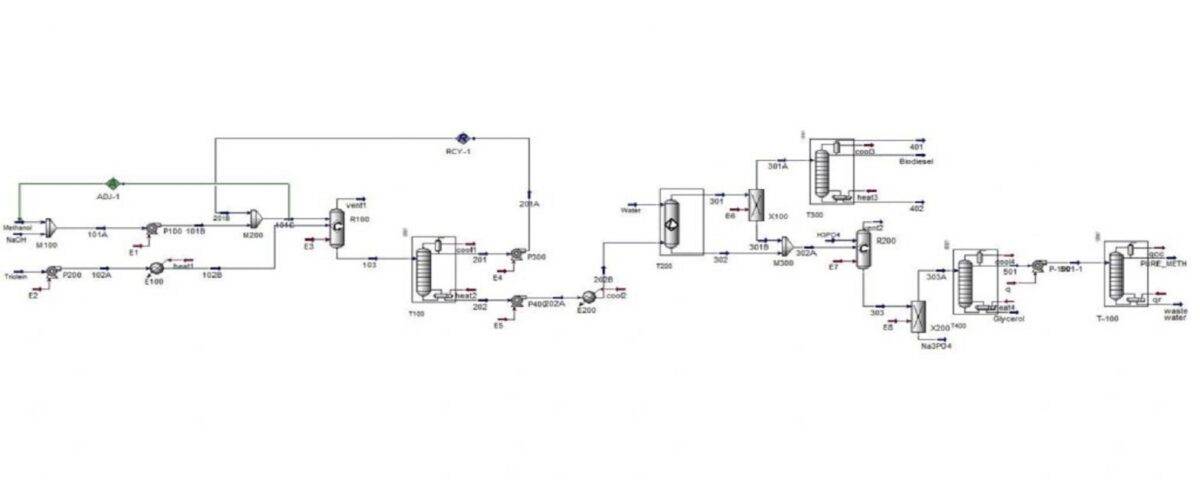

Simulation of the Biodiesel Production Process

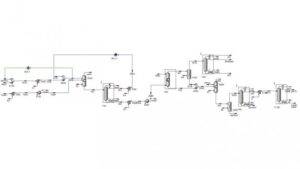

The simulation of the biodiesel production process using Aspen HYSYS software involves several steps that assist in the analysis and optimization of this process’s performance. Initially, the raw materials for biodiesel production are identified, typically including vegetable oils or animal fats and methanol. Next, appropriate thermodynamic models are selected for the system to accurately simulate the physical and chemical properties of the components. In the subsequent step, operational units such as reactors (for performing the transesterification reaction), separators (for separating glycerin and biodiesel), and purification equipment (for improving biodiesel quality) are created in the software.

Each unit is configured by determining operational parameters such as temperature, pressure, and residence time. After that, the process simulation is run, and outcomes such as process yield, production costs, and product quality are evaluated. These analyses enable the optimization of operational conditions, thereby increasing production and reducing costs in the biodiesel production process.

In this project, the simulation of the biodiesel production process in Aspen HYSYS software has been conducted.

Conclusion

The simulation of the biodiesel production process using Aspen HYSYS software demonstrates that this tool can significantly contribute to optimizing and improving the efficiency of biodiesel production. By accurately simulating the associated reactions and processes, researchers and engineers can identify optimal conditions for maximizing the yield of converting vegetable oils and animal fats into biodiesel.

Furthermore, the results obtained from the simulation assist in cost analysis and help determine the strengths and weaknesses of the process, potentially leading to better decision-making regarding the development and commercialization of this technology.

Simulation of the Biodiesel Production Process (Project No. 4) Using Aspen HYSYS

In this project, the simulation of the biodiesel production process (Project No. 4) using Aspen HYSYS software has been carried out.