Introduction

LORDEGAN Petrochemical Complex is located in FALAR region, CHARMAHAL and BAKHTIARI Province, 55 kilometers away from LORDEGAN city. Established in 2008, the company enjoys a favorable geographic location due to its proximity to water and gas resources, three national gas pipelines, and a suitable, leveled site for infrastructure development. The company produces ammonia with a daily capacity of 2050 tons and urea with a daily capacity of 3250 tons.

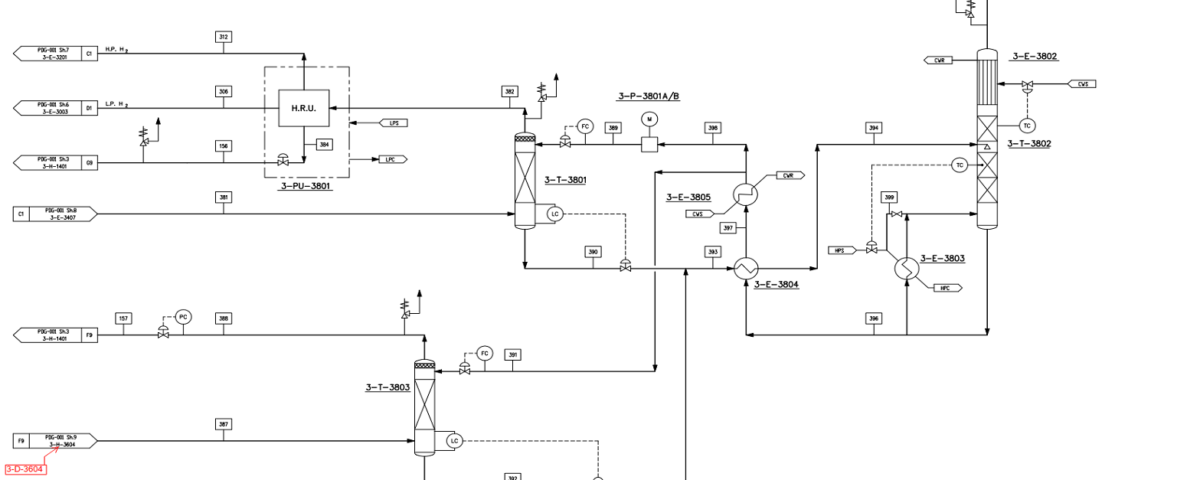

Process Description

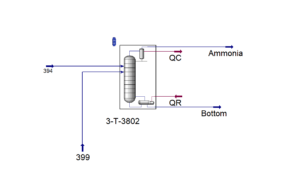

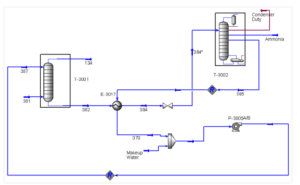

One of the most crucial steps in simulation is selecting the appropriate thermodynamic equation of state for estimating thermodynamic properties. All results obtained from the software are estimated and presented using this equation. Consequently, choosing the right equation of state can enhance the simulation’s validity and reduce errors. The lower the error in the simulation, the smoother the study becomes. The following figure illustrates the simulation of Tower T-3802 in LORDEGAN Petrochemical Complex using Aspen HYSYS software.

Optimization Description

Optimization is achieved by adding a condenser and reducing the pressure drop in the reflux drum. In addition to reducing the pressure drop in the reflux drum and its impact on utility reduction, the use of internal reflux for the reflux drum is proposed. By internal reflux, it is meant that unlike the current process, pure ammonia is not used for reflux, and by using a total condenser, an optimal amount of reflux is returned from the overhead vapor back to Tower 3802-T.

Conclusion

Simulation results for the current unit’s reflux section pressure drop and the addition of a condenser to Tower 3802 (with the hydraulics of Tower 3802-T held constant) showed that there is no need for the solvent cooling cooler 3019-E due to improved heat transfer in the heat exchanger before Tower 3802-T and the recovery of 18,020 kg/h of cooling water. Replacing high-pressure steam with low-pressure steam in the reboiler, due to the decrease in reboiler temperature, and also reducing the utility consumption in the reflux drum reboiler by up to 1802 kg/h. Reflux supply for the reflux drum is possible by using a condenser and optimizing reflux up to 39.35 kmol/h.

To Enhance the Performance and Efficiency of the Ammonia Production Unit at LORDEGAN Pet. Co Company, SANILCO Company has Conducted Comprehensive Simulation and Optimization studies on the Key Equipment and Processes of this Unit. These Studies Include:

- Simulation and optimization of Tower T-3802 (ammonia separation) in LORDEGAN Pet. Co. Company

- Simulation of the Ammonia separation and recovery unit of LORDEGAN Pet. Co. Company under Casale license

- Optimization and cost reduction of the ammonia and water separation distillation tower (LORDEGAN Pet. Co. Company)

Simulation and Optimization of T-3802 (Ammonia Separation) in LORDEGAN Pet. Co. Company

In this project, the simulation and optimization process of Tower T-3802 (ammonia separation) in LORDEGAN Pet. Co. Company has been simulated using Aspen HYSYS version 14.