Introduction

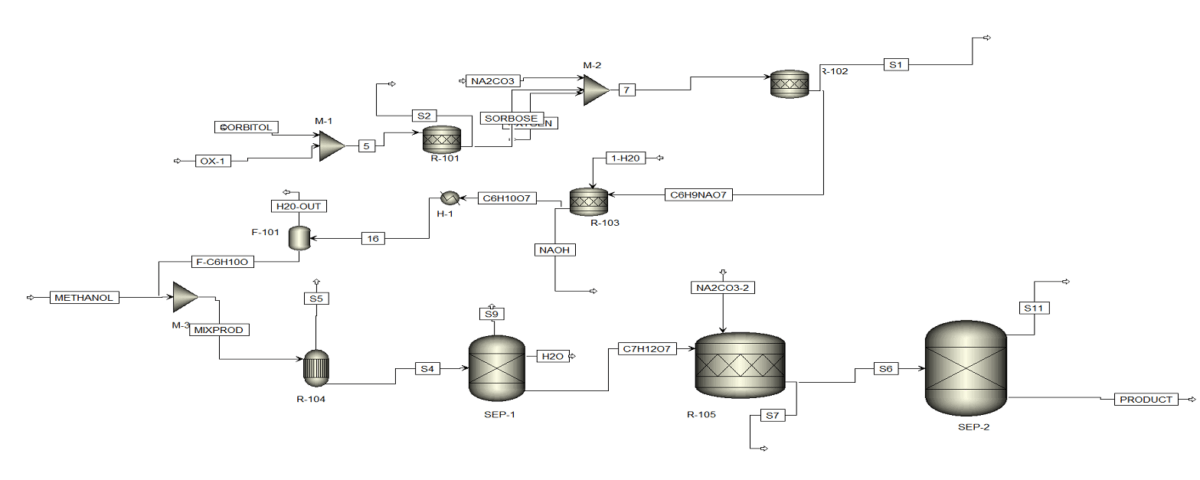

The current project titled ascorbic acid simulation using Aspen Plus deals with the modeling and optimization of ascorbic acid (vitamin C) production process. Ascorbic acid is a vital, water-soluble compound. which is widely used in the food and pharmaceutical industries to strengthen the body’s immune system and as an antioxidant. The aim of this project is to simulate the production process of this material and apply the necessary changes and optimizations to improve performance and reduce production costs.

Project Objectives

Modeling of Ascorbic Acid Production Process:

Using Aspen Plus software for accurate modeling of the ascorbic acid production process, including all operational units and required equipment.

Optimizing Operational Parameters:

Investigating and optimizing key operating parameters such as temperature, pressure, reaction input composition and flow rates to achieve the highest production efficiency and lowest cost.

Economic and Energy Analysis:

Conducting economic and energy analyzes in order to reduce production costs and optimize energy consumption in the process.

Changes and Optimization

Based on the simulations and analysis, the following changes and optimizations have been applied to improve the ascorbic acid production process:

1. Remodeling of The R-101 Reactor:

R-101 reactor was changed from RStoic model to RPlug to increase reaction efficiency and provide more optimal operating conditions.

2. Recovery of Chemicals From The C-101 Waste Stream:

By adding an additional distillation column, chemical recovery from the waste stream was optimized and operating costs were reduced.

3. Accurate Sizing of HX-101 Heat Exchanger:

The sizing of HX-101 heat exchanger was done using EDR analysis to optimize heat transfer and reduce energy consumption.

4. Adding a New Block for Recycling Isovaniline:

A special design block was added to simulate isovaniline recycling, which resulted in reduced production costs and increased process efficiency.

5. Economic and Energy Analyses:

Economic and energy analysis (AEA) tools were applied to evaluate capital and operating costs and improve energy savings in the process.

Conclusion

The ascorbic acid production simulation project using Aspen Plus showed that by optimizing the operating parameters and using advanced simulation tools, significant improvements can be made in the ascorbic acid production process. These improvements lead to reduced production costs, increased efficiency and optimization of energy consumption in the process.

Simulation and Optimization of Ascorbic Aacid Production Process

In this project, the simulation of ascorbic acid production has been done using Aspen Plus software, and the operational parameters have been analyzed and optimized.