Introduction

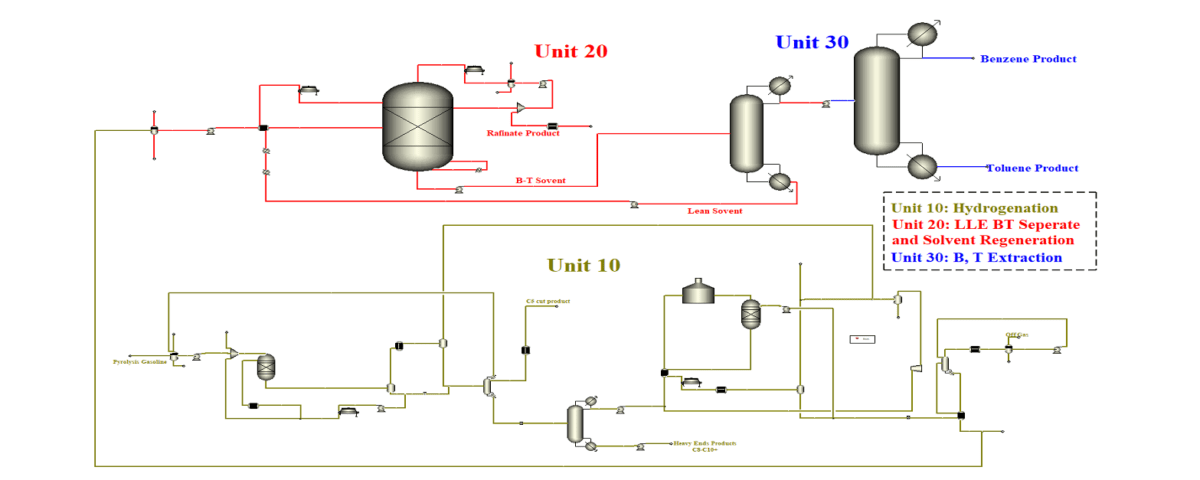

Damun Refining Petrochemical Company (Private Joint Stock) is engaged in a project aimed at producing benzene and toluene as one of the leading initiatives in the petrochemical industry, approved by the National Petrochemical Company (NPC), located in the Mahshahr Free Petrochemical Zone. This project includes five main units: hydrogenation, extraction distillation, purification, storage tanks, utilities, and off-site facilities. Its products consist of benzene, toluene, gasoline, and fuel oil. The feedstock utilized in this project amounts to 80,000 tons of pyrolysis gasoline per year. The basic engineering and technical knowledge of the aromatic unit of Damun Petrochemical Company has been developed through reverse engineering by domestic knowledge-based companies. After obtaining the initial approval, geotechnical and environmental impact studies (EIA) have also been conducted. Land acquisition and consolidation have been implemented over an area of 1.2 hectares, along with fencing around the site.

Process Description

Simulation and feasibility studies are employed as analytical methods to predict and evaluate the effects of various decisions and changes within a system. This approach allows us to simulate diverse hypotheses and scenarios while performing different forecasts and analyses.

Our experts in the simulation department utilize various modeling and feasibility assessment methods across different fields, including oil and gas, power plants, and metal and mining industries, employing advanced software such as ASPEN Plus to assess and evaluate with the goal of improving system performance and developing products.

In general, the steps of simulation and feasibility studies in the simulation department of Damun Petrochemical Company are as follows:

1. Define Objective: Identify the primary goal of the process simulation and feasibility study.

2. Select Variables: Identify and select key variables that significantly affect the process, to be incorporated into the mathematical model.

3. Choose Model: Select a mathematical model that accurately represents the targeted process.

4. Data Collection: Gather the necessary data required for input analysis and simulation execution.

5. Create Simulation: Implement the mathematical model in simulation software and input data to run the simulation.

6. Analyze Results: Study and analyze the results obtained from the simulation to evaluate the impacts of various changes on the process.

7. Evaluate Scenarios: Assess multiple scenarios and make decisions based on the results derived from the simulation.

Conclusion

To determine the optimal investment volume, reduce risk, and forecast revenues and costs associated with the project, conducting pre-investment studies is essential. Therefore, this study encompasses market research and the feasibility of technical, financial, and economic aspects of various petrochemical products. The outcome of these studies will provide estimates for the optimal investment volume, revenue potential, and financial indicators, as well as project financing methods.

Simulation and FS of Damun Pet. Co. Aromatic Plant Licenses

In the project the simulation of Damun Petrochemical Company’s technical knowledge has been done for economic assessment using Aspen Plus.