Description

Methanol, methyl alcohol, carbinol or wood alcohol, which is the simplest type of alcohol. It is known by the chemical formula CH3OH. Methanol is produced from the anaerobic activity of many species of bacteria. And as a result, a small amount of methanol vapor enters the atmosphere. And after several days it is oxidized by oxygen and with the help of sunlight and turns into water and carbon dioxide.

Of course, in the process of burning methanol, this happens in terms of the materials obtained, but much faster. At the same time, the burning flame of methanol is colorless and care must be taken so that its flame does not cause burns. However, methanol is far more toxic than ethanol. With production of over 20 million tons per year, it is used as a precursor to other commodity chemicals including formaldehyde, acetic acid, methyl tert-butyl ether, as well as a host of more specialized chemicals.

Simulation and Design of Methanol Production Unit in Aspen Plus

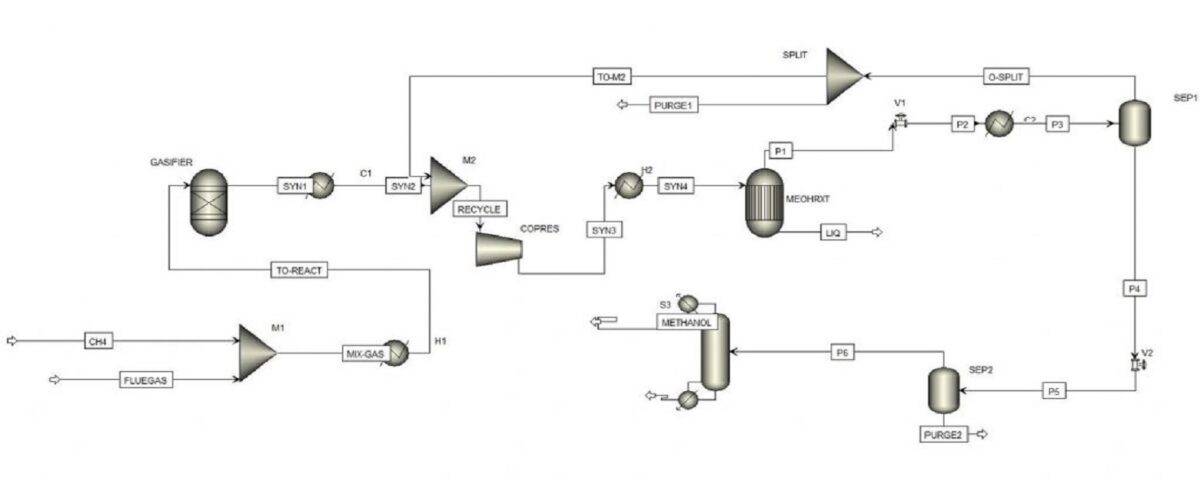

The simulation and conceptual design process of a methanol production unit in Aspen Plus involves several steps. Initially, a conceptual model of the methanol production unit is created by defining the feeds, products, and the type of feedstock (typically natural gas or synthesis gas). Next, using appropriate thermodynamic equations and selecting the correct simulation modules, various units such as reactors, heat exchangers, and distillation columns are integrated into the model. Operational parameters such as temperature, pressure, and reactant ratios are then adjusted. Results are analyzed to assess key performance indicators like production efficiency, energy consumption, and economic requirements, enabling necessary optimizations. Ultimately, this simulation helps engineers and designers to develop an effective and cost-efficient process for high-performance methanol production.

In this project, which was carried out with the help of Aspen Plus software, the aim is to simulate a methanol production unit from natural gas feed. The figure below shows the overview of the unit pfd.