Introduction

Poly Aluminum Chloride (PAC), a widely used coagulant in water and wastewater treatment, is available in both food-grade and industrial-grade forms. It is also known by various names such as polyaluminum chloride, coagulant, PAC coagulant, aluminum chloride hydrate, liquid PAC, solid PAC, PAC for water treatment, liquid PAC, solid PAC, white PAC, yellow PAC, industrial PAC, wastewater PAC, potable PAC, and hygienic PAC.

Applications of Poly Aluminum Chloride

Studies have shown that the most significant application of PAC is in water treatment, specifically in the coagulation and flocculation stages. Although alternative materials exist, the superior properties of PAC have led many developed countries to prioritize its use in water treatment over other coagulants.

Types of Poly Aluminum Chloride

PAC is primarily categorized into two main types: food-grade or potable (hygienic) PAC and industrial (wastewater) PAC. Both types can be produced in either solid or liquid form.

Production Process of Poly Aluminum Chloride

Several methods can be employed to produce PAC, including thermal decomposition, electrolysis, membrane reactors, and acid-base dissolution. A typical PAC production line consists of the following six sections:

- Raw material storage and transfer system

- Main reactor for acid-aluminum combination

- Polymer maturation and processing tank

- Filtration and product purification

- Spray dryer

- Weighing unit

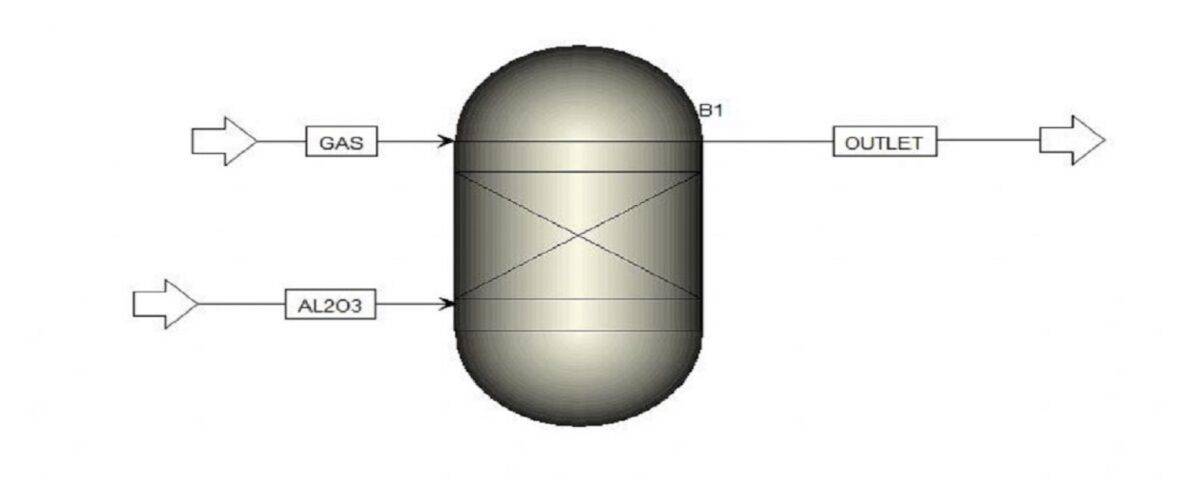

Simulation and Conceptual Design of a Poly Aluminum Chloride Production Reactor

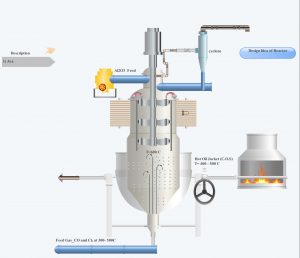

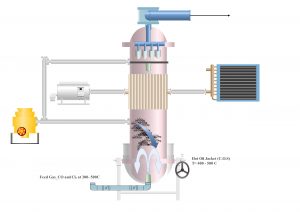

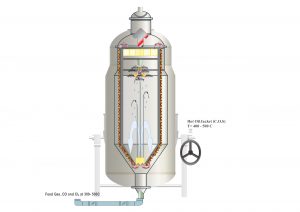

In this project, the simulation and conceptual design of a polyaluminum chloride production reactor were conducted using Aspen Plus software. The following figures illustrate the conceptual designs of the aluminum chloride reactor.

Design of Stirred Reactor and External Coil

Jacketed and Internally Coiled Fluidized Bed Reactor

Jacketed and Externally Coiled Fluidized Bed Reactor

After conducting comprehensive simulations and finalizing the 3D model, the design with all technical details is sent to the manufacturing workshop to start the production process.

Feasibility Study and Simulation of the Poly Aluminum Chloride Production Reactor with Aspen Plus

This project presents a simulation and conceptual design of a polyaluminum chloride production reactor with Aspen Plus.