Introduction

Shell & Tube heat exchangers are widely recognized as highly effective equipment in industrial processes, allowing for efficient heat transfer between fluids at different temperatures. Known for their straightforward structure, high efficiency, and reliability, Shell & Tube heat exchangers are commonly used across oil and gas, chemical, and power industries. A well-optimized design of these exchangers can dramatically increase energy efficiency, lower costs, and enhance overall system performance.

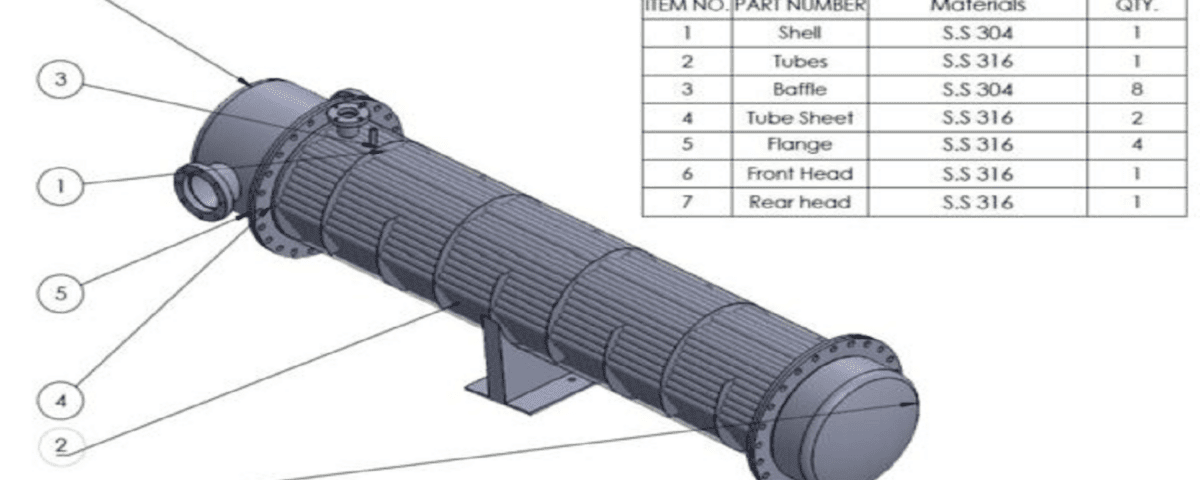

In this project, our primary objective was to design a Shell & Tube heat exchanger using SolidWorks. This involved meticulous attention to essential parameters such as the number of tubes, tube diameter, material selection, and optimized fluid inlet and outlet configurations. The design prioritizes thermal and mechanical efficiency while keeping production costs low.

Project Overview

This project involved the creation of a Shell & Tube heat exchanger with dual fixed heads, manufactured from S.S 316L, making it suitable for various chemical applications. Upon completion, this project offers five detailed construction sheets: Body Drawing, Bill of Materials, Tube Sheet & Baffle Drawing, Tubes & Flange Drawing, and Nozzle Orientation Layout. All diagrams are provided in AutoCAD format, along with the 3D models in SolidWorks.

This heat exchanger was constructed in 2019 at a resin and paint processing facility in Shiraz Industrial City, where it is currently operational, demonstrating robust performance and reliability.

conclusion

In conclusion, the design of a Shell & Tube heat exchanger in SolidWorks demonstrates the effectiveness of advanced CAD tools in engineering applications. Through a systematic approach, starting from defining design parameters and material specifications to creating detailed 3D models, engineers can achieve optimal designs that meet the required thermal and hydraulic performance criteria. The simulation capabilities of SolidWorks further enable the analysis of flow patterns, heat transfer coefficients, and pressure drops, allowing for refinement of the design to enhance efficiency and reliability. Ultimately, this process not only streamlines fabrication and installation but also contributes to improved energy efficiency and cost-effectiveness in thermal management systems across various industries. The successful completion of a Shell & Tube heat exchanger design in SolidWorks exemplifies the integration of design precision and practical engineering solutions.