Introduction

Fuel tank explosion modeling is a critical task in assessing the safety and structural integrity of industrial facilities, especially in the oil and gas sector. To ensure accurate and reliable simulation, industry standards such as those developed by DNV and Total are applied. These standards provide guidelines for the time-dependent behavior of explosions, which are essential for creating realistic models.

Phast is a complex software that is used to simulate the explosion and its impact on structures. It involves complex physical phenomena, including fluid dynamics, thermodynamics and material response, to predict the consequences of explosive events. In this project, our goal is to model a fuel tank explosion using phast software, following the standard time parameters specified by DNV and Total.

Description of The Process

Propane tank explosion modeling in phast software to calculate its consequences in two standard times. It usually involves a detailed process following DNV and Total guidelines. which requires a correct understanding of the software and methods determined by these standards. Here is an overview of the steps involved:

1. Define The Scenario:

– Specify the size and type of propane tank.

– Determine the location of the tank and the surrounding environment.

– Determine the type of explosion (for example, BLEVE – Boiling Liquid Expanding Vapor Explosion).

2. Enter The Tank and Propane Specifications:

– Tank volume

– Propane pressure and temperature conditions.

– Physical properties of propane (density, heat capacity, etc.).

3. Set The Explosion Parameters:

– Define the type of explosion and its characteristics.

– Specify overpressure thresholds and other relevant criteria based on DNV and Total standards.

4. Select The Outcome Modeling Method:

– Select the appropriate model for the overpressure of the explosion and the effect of heat radiation.

– DNV and Total may have specific models or experimental data to use.

5. Run The Simulation:

– Enter all defined parameters in Phast.

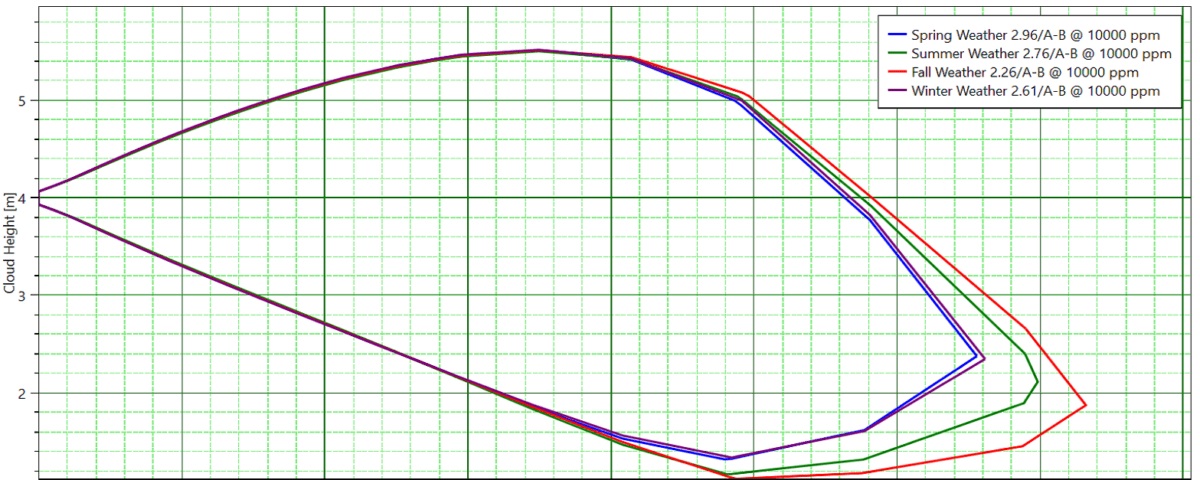

– Run the simulation to calculate the consequences (overpressure, heat radiation, part ejection, etc.) at different intervals and times.

6. Extracting The Results:

– Retrieve results for overpressure, thermal radiation and other effects at specified times.

– Normally, the results are analyzed in two standard times:

– Maximum overpressure time.

– Time of maximum thermal radiation.

7. Analysis and Comparison With Standards:

– Compare the results with the acceptance criteria specified by DNV and Total.

– Ensure that results comply with safety regulations and guidelines.

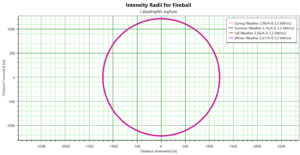

Here are pictures of propane tank explosion modeling to two standard orders (DNV, Total):

Conclusion

By modeling a fuel tank explosion at the standard times specified by DNV and Total in Phast software, a deeper understanding of explosion dynamics and its effects on industrial infrastructure can be achieved. This knowledge is essential to designing safer facilities, implementing effective mitigation measures, and complying with regulatory standards.

In conclusion, the integration of standard DNV and Total times into Phast simulations provides a robust framework for assessing the risks associated with fuel tank explosions. The insights gained from this study will help increase the safety and flexibility of industrial operations.

Propane Tank Explosion Modeling (DNV, Total) With Phast

In this project, the explosion of a propane tank in a standard door (DNV, Total) is modeled by phast software. The project has a report.