Introduction

ILAM Pet. CO. is one of the largest and most significant petrochemical complexes in Iran, located in Ilam Province. Equipped with advanced technologies and modern equipment, it is capable of producing a variety of petrochemical products, including polyethylene, polypropylene, and other chemical products. The complex is recognized as a driving force in the region’s economic development and job creation.

Due to its favorable geographical location and access to natural gas and oil resources, Ilam Petrochemical can easily secure the necessary raw materials and contribute to the economic prosperity of the region by utilizing local labor. Additionally, the complex prioritizes safety principles and its social responsibilities while serving as a successful model for construction and environmental projects.

Ilam Petrochemical aims to increase production capacity and improve product quality through the expansion of its production lines and the establishment of new phases. Because of its positive impacts on regional infrastructure and job opportunities for local youth, it is considered a successful investment in Ilam Province. Overall, ILAM Pet. CO. plays a key role in the development of the country’s petrochemical industry and can act as a central hub for economic progress at national and international levels.

In addition to its economic impacts, ILAM Pet. CO. takes its social responsibilities seriously. These include supporting educational and healthcare projects, as well as developing public infrastructure, thereby enhancing the quality of life in the local community. ILAM Pet. CO. seeks to establish closer relationships with universities and research centers and contributes to the development of new technologies in the petrochemical industry through scientific and research collaborations. These relationships can enhance the quality of education and training for skilled human resources in this industry, addressing existing challenges in production and the adoption of new technologies.

Moreover, considering environmental concerns, ILAM Pet. CO. has implemented systematic plans to preserve the environment and prevent pollution. The complex aims to reduce negative impacts on nature and preserve natural resources by employing clean methods and using less polluting technologies. One of the main goals of this complex is sustainable productivity and long-term environmental preservation alongside economic development.

Process Description

Propylene is a vital petrochemical product mainly used in polypropylene production. The separation of propane and propylene presents significant challenges due to their similar physical properties and molecular sizes.

Similar Properties: Propane and propylene have molecular sizes and physical characteristics that are close to each other, making their effective separation difficult through conventional methods like distillation.

High Energy Consumption: The distillation process typically requires a high energy input, characterized by high reflux ratios (usually between 10 to 20) and pressures ranging from 16 to 26 atm. This results in significant energy costs, especially with rising energy prices.

Capital Costs: The initial investment for establishing distillation columns capable of separating these gases is high, increasing the economic complexities of the separation process.

Lack of Efficiency in Alternative Methods: While alternative methods such as absorption, adsorption, and extractive distillation have been explored, they have not demonstrated sufficient advantages over traditional distillation techniques.

Need for Optimization: Continuous optimization of operational parameters is essential to improve product quality and reduce energy consumption. However, achieving this balance can be complicated due to the interactions between various factors such as reflux ratio, column pressure, and feed stage location.

These challenges highlight the need for ongoing research and development in separation technologies to enhance efficiency and reduce costs in the propane and propylene separation process.

Objective: This study aims to investigate optimal operational parameters for the distillation process to enhance product quality and improve energy efficiency.

Process Simulation

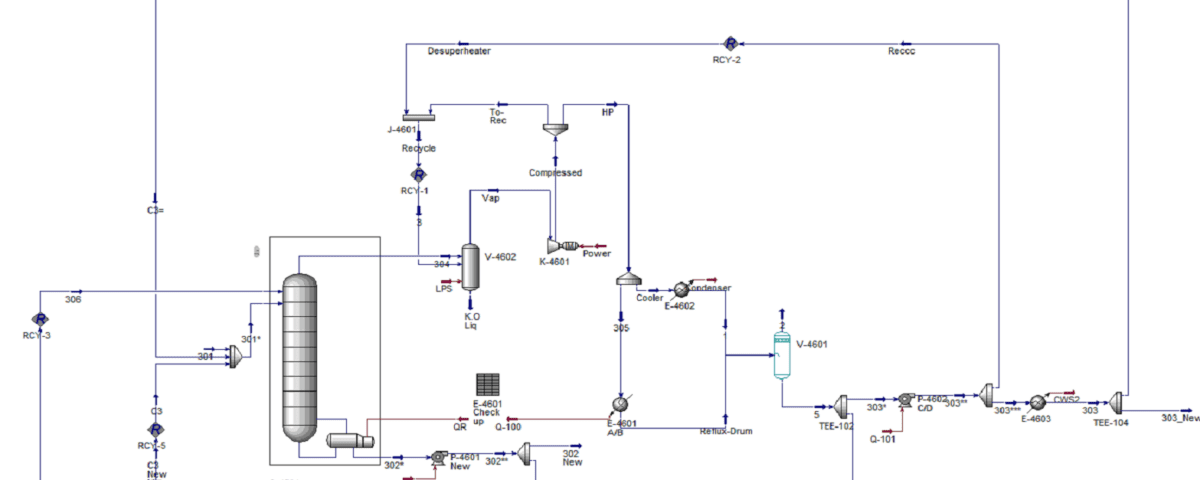

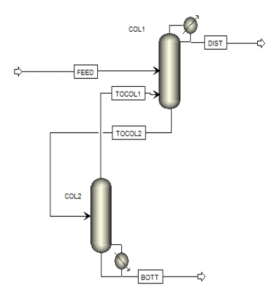

– Simulation: Hysys simulation software was used to model the distillation column.

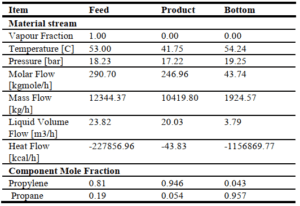

– Operational Conditions: Initial conditions included a feed of 55.32 kmol/h of propylene, a reflux ratio of 10.2, and a column pressure of 18.23 atm.

Performance Analysis

Yield Optimization: The simulation aimed to achieve a minimum purity of 94% of propylene in the distillate product, which was achieved by adjusting operational parameters, resulting in a purity exceeding 95%. The simulation and analysis of the distillation column indicated that by adjusting the reflux ratio from 10.2 to 10.02 and increasing the column pressure from 18.23 atm to 20.2 atm, the purity of propylene in the distillate could increase from 94.7% to over 95%.

Energy Efficiency: This optimization led to a significant reduction in steam input energy, indicating an approximate saving of 106 kcal/h, thus improving energy efficiency in the separation process.

Operational Guidelines: The results provide valuable insights into the operational parameters that can be adjusted for better control and efficiency in the propane-propylene separation process, contributing to a deeper understanding of its dynamics.

The findings suggest that while alternative separation methods have been explored, optimizing existing distillation processes remains critically important until more effective technologies are developed. This study emphasizes the significance of continuous improvement in operational parameters for enhancing product quality and energy efficiency in petrochemical processes.

Response Optimization

– Using statistical software (Minitab), this study optimized conditions to maximize propylene yield while minimizing steam load, achieving a purity of over 95% with reduced energy needs.

Key Factors Influencing Energy Consumption in Propylene and Propane Distillation:

1. Reflux Ratio: A higher reflux ratio typically improves separation efficiency but increases energy consumption due to the additional heat required for the vaporization and condensation processes. The study shows that reducing the reflux ratio from 10.2 to 10.02 can lead to significant energy savings while maintaining high propylene purity in the distillate.

2. Column Pressure: Operational pressure affects the boiling points of components and the energy needed for steam generation. Reducing the column pressure can increase propylene purity but may raise the steam load, resulting in higher energy consumption. The study showed that increasing column pressure from 18.23 atm to 20.2 atm while optimizing other parameters resulted in lower steam energy input.

3. Feed Stage Location: The position of the feed stage within the distillation column affects the separation efficiency. This study demonstrates that placing the feed stage between trays 56 and 75 optimizes propylene yield while also influencing steam energy requirements.

4. Steam Load: The steam load directly reflects energy consumption in the distillation process, indicating that precise control of operational parameters can lead to reduced energy needs.

5. Material and Energy Balances: Effective management of material and energy balances throughout the distillation process is essential for optimizing energy consumption. This includes monitoring flow rates, temperatures, and pressures to ensure efficient operation and minimize waste.

By fine-tuning these factors, both product quality and energy efficiency in the separation of propane and propylene can be improved, which is particularly crucial given rising energy costs and environmental considerations in oil refining processes.

The reflux ratio plays a vital role in influencing energy consumption in the propylene and propane distillation process. Here’s how it impacts the process:

1. Separation Efficiency: A higher reflux ratio improves separation efficiency by increasing the number of theoretical stages in the distillation column, leading to better purification of propylene from propane, which is vital given their similar physical properties. However, this increased efficiency comes at a cost and raises energy consumption due to the additional heat input required for the vaporization and condensation processes.

2. Energy Demand: As observed in the study, increasing the reflux ratio typically leads to higher steam loads, which are directly related to energy consumption. For example, maintaining a high reflux ratio (around 10-20) requires significant energy input to keep the system functioning effectively. In contrast, reducing the reflux ratio can decrease energy needs but might negatively impact product purity.

3. Optimal Conditions: Research has shown that optimizing the reflux ratio can lead to notable energy savings while still maintaining high levels of propylene purity. For instance, lowering the reflux ratio from 10.2 to 10.02 led to a significant reduction in steam energy input while still preserving propylene purity above 95%.

4. Trade-offs: A delicate balance exists between achieving high product purity and minimizing energy consumption. Reducing the reflux ratio can cut energy costs but may require close monitoring to ensure product quality does not drop below acceptable levels.

5. Pressure Effects: The interplay between reflux ratio and column pressure is also critical. Lowering column pressure while adjusting the reflux ratio can positively affect propylene yield but may further increase steam load, necessitating precise optimization.

In summary, while increasing the reflux ratio enhances separation efficiency, it also significantly raises energy consumption. Therefore, optimizing this parameter is essential to achieving a balance between energy efficiency and product quality in the distillation of propylene and propane.

Optimal Reflux Ratios for Minimizing Energy Consumption in Propylene-Propane Distillation:

1. Initial Operational Conditions: This study started with a reflux ratio of 10.2, identified as a standard operational condition for achieving acceptable propylene purity.

2. Optimization Results: Through simulation and analysis, it was determined that reducing the reflux ratio to approximately 10.02 significantly improved energy efficiency while maintaining high levels of propylene purity in the distillate.

3. Pressure Considerations: The optimization process also included adjusting the column pressure. The study indicated that keeping the column pressure below 20 atm while using a lower reflux ratio allows for higher propylene yields (over 95%) in the distillate, with reduced energy consumption.

4. Energy Savings: These adjustments resulted in a notable reduction in steam energy input, approximately 106 kcal/h, demonstrating that careful management of the reflux ratio and pressure can lead to substantial energy savings.

5. Trade-offs: While lower reflux ratios can reduce energy consumption, they must be balanced against the need to achieve desired product purity levels. This study suggests that operational conditions should be adjusted in accordance with specific production goals for optimal performance.

In conclusion, the optimal reflux ratio for minimizing energy consumption in the distillation of propylene and propane is approximately 10.02, particularly when combined with appropriate pressure settings to enhance overall efficiency and product quality.

Conclusion

This study successfully simulated and optimized the propane-propylene separation operation, demonstrating that precise adjustments in the reflux ratio and column pressure can lead to significant improvements in product quality and energy efficiency. The findings provide valuable insights for future operations.

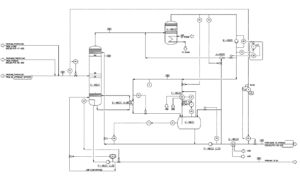

This project was simulated and subsequently optimized by APIPCO, assisted by data and diagrams from the petrochemical industry.

Simulation and Optimization of Propane-Propylene Separation in Ilam Petrochemical Unit 4600

In this project, the simulation and optimization of the propane-propylene separation process at Ilam Petrochemical Unit 4600 were conducted using Aspen HYSYS version 14. This project includes complete industrial reports and detailed training.