Introduction

The world’s current annual energy demand stands at approximately 120 quadrillion kilocalories and is projected to increase by 50% over the next two decades. The primary energy source, however, fossil fuels, will not be able to meet this projected increase in demand, primarily in terms of sustainability. A combination of declining supply and environmental remediation costs is expected to drive up the effective cost of oil, thereby raising the issue of new energy sources. Against this backdrop, biomass has emerged as a potentially attractive and economical alternative to oil due to several of its attributes. In light of environmental concerns and regulations, biomass also presents itself as a renewable and clean source.

Fast Pyrolysis of Biomass

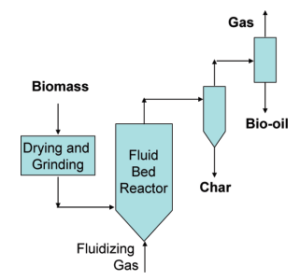

Biomass conversion processes include direct combustion, pyrolysis, and gasification. Biomass pyrolysis is a thermal process that occurs in the absence of oxygen and results in the production of char, liquid, and gas. Pyrolysis is also the first stage in gasification and combustion processes. Lower temperatures and longer residence times have been shown to favor the production of char at the expense of the gas and tar released by the biomass, while short residence times and intermediate temperatures optimize the yield of liquid or bio-oil. Higher temperatures and longer residence times enhance the role of the secondary decomposition of primary products, which favors conversion to gaseous products. The figure below shows a highly schematic view of the fast fluidized bed pyrolysis process. Biomass is dried to minimize the water content in the bio-oil product and is finely ground to ensure small particles and rapid drying and reaction.

High Potential of Sesame Stalk for Bio-oil Production

Sesame oil, due to its nutritional properties and wide range of applications, holds a special place in the food and cosmetic industries. However, recent research has shown that other parts of the sesame plant can also provide significant added value. One of these parts is the sesame stalk, which has high potential for bio-oil production. Bio-oils, as clean and renewable alternatives to fossil oils, have gained increasing importance. Sesame stalks, with their significant oil content and high oxidative stability, have emerged as a promising source for producing these types of oils.

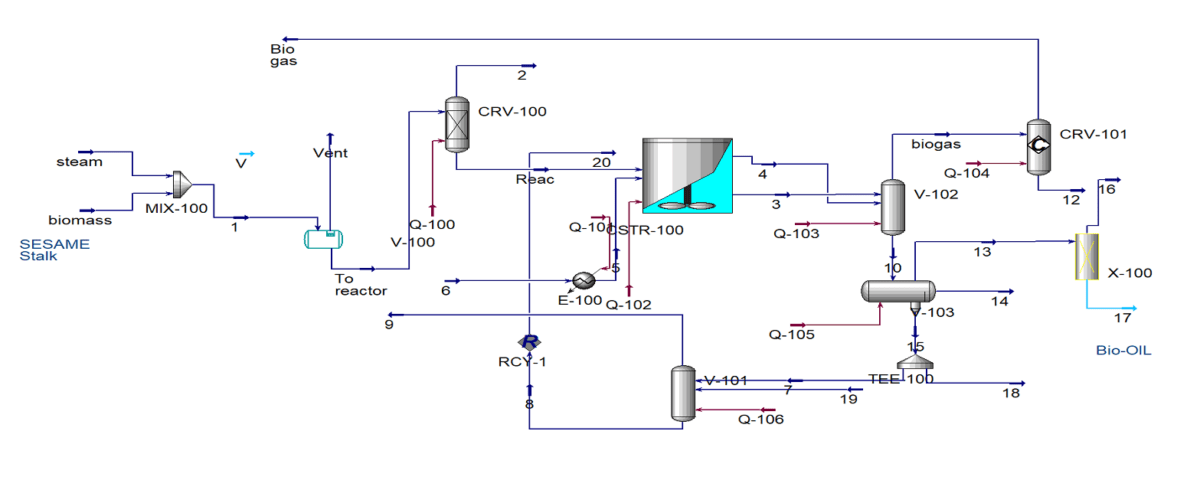

Process Description

Biomass pyrolysis is a process in which biomass, such as sesame stalks, is heated in the absence of oxygen at high temperatures. This process results in the production of three main products:

- Bio-oil: A liquid product rich in organic compounds that has high potential for producing biofuels.

- Biochar: A solid material with a porous structure that has various applications in agriculture, water treatment, and carbon sequestration.

- Non-condensable gas: A mixture of various gases such as hydrogen, methane, and carbon monoxide that can be used as fuel or as a feedstock for producing chemicals.

Simulating this process allows us to gain a deeper understanding of reaction mechanisms, the impact of operating parameters, and process optimization before conducting practical experiments.

Simulation Stages

- Biomass: First, the exact chemical composition of the sesame stalk (cellulose, hemicellulose, lignin, minerals, etc.) must be determined. This information is entered into the simulator as input.

- Physical Properties: Physical properties such as density, viscosity, and heat capacity are also essential for accurate modeling.

- Pyrolysis Unit: The complex reactions of biomass pyrolysis, including the thermal decomposition of biomass into gaseous, liquid (bio-oil), and solid (char) products, must be accurately defined in the simulator.

- Operating Conditions: Operating parameters such as temperature, pressure, and residence time in the pyrolysis unit affect the yield and quality of the products.

- Product Separation: The liquid products obtained from pyrolysis are typically a mixture of various compounds. Distillation units are used to separate bio-oil from other compounds. In some cases, extraction methods are used to improve the purity of bio-oil.

- Oil Purification: Raw bio-oil contains impurities such as water, free fatty acids, and organic compounds that must be removed. Purification methods such as washing, drying, and filtration are used for this purpose.

Conclusion

The simulation usually determines the exact distribution of the products obtained from the process of pyrolysis of sesame stem biomass, including bio-oil, biogas, water and other by-products. With input and output energy calculations, the overall efficiency of the process and the amount of energy consumption are determined. Simulation can help to identify and quantify the types of pollutants in the final products. By changing the process variables, such as temperature, pressure and air-fuel ratio, it is possible to achieve optimal conditions for maximum efficiency and minimum production of pollutants.

Simulation of Sesame Stem Bio-Oil Production From Biomass Pyrolysis

In this project, the process of simulating the production of sesame stem bio-oil from biomass pyrolysis has been simulated with Aspen Hysys version 14 software. The project has a complete report (pdf file).