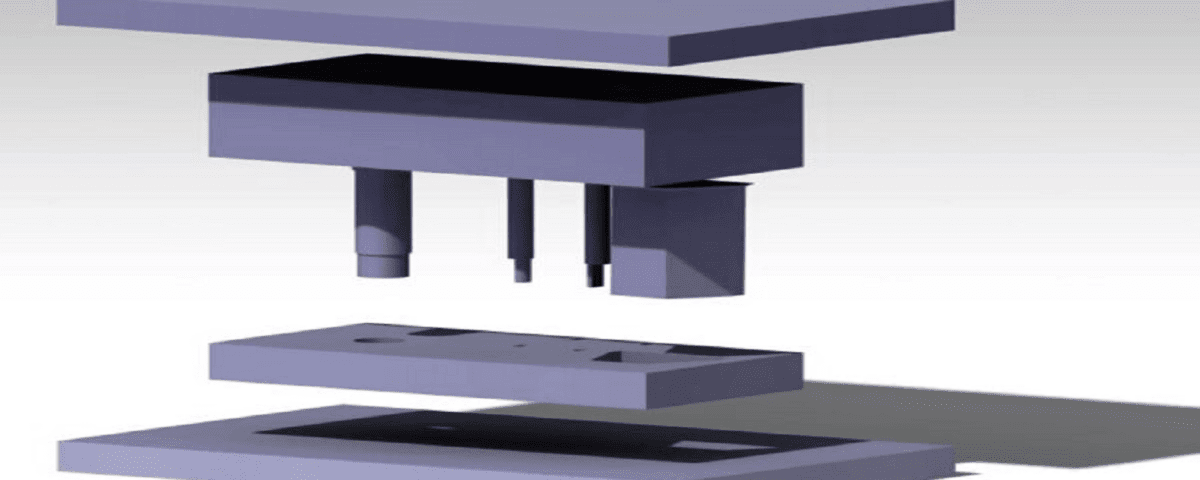

Description

The processes involved in shaping metal sheets are among the most critical manufacturing processes in the industry. The force required to shape metal sheets is supplied by press machines. In this context, the die serves as a tool that transmits the force from the press to the sheet, creating the desired shape on the material. Dies used for shaping sheets are commonly known as press dies and include cutting, bending, and deep drawing dies. Generally, in industrial applications, the processes of cutting, bending, and deep drawing are performed using stage or progressive dies to manufacture a part. These dies contain various stations, with each station performing one or multiple operations. Ultimately, the final part is produced at the last station.

When designing a press die, it is essential to study and analyze various issues related to pressing, including the presses, dies, the usage of the dies, and the specific part to be manufactured. The design must be efficient and significant, enabling the production of a large number of parts in a shorter time frame.

Press Mold Design Software

CATIA: One of the most widely used software for designing complex molds.

SolidWorks: Powerful software for 3D modeling and simulating the pressing process.

AutoCAD: Used to create 2D drawings of molds.

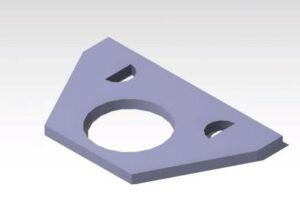

Press Die Design for a Specific Part

The aim of this project was to design a press die. This press die has been modeled in 3D using CATIA software. Upon purchasing this project, you will gain access to the manufacturing drawings and the 3D model.