Introduction

Potassium nitrate, or saltpeter, is a chemical compound with the formula KNO3. This substance occurs naturally in places such as cave walls as a white powder. Potassium nitrate is a relatively strong oxidizer and absorbs water well, which can lead to spoilage in products like gunpowder that utilize saltpeter when exposed to air.

One important reaction involving potassium nitrate is its reaction with sugar, which is used in many rocket fuels. This reaction produces H2O and N2, creating a dense smoke cloud that can be used as a smoke bomb. However, the reaction requires precise ratios to function correctly, specifically a 1:6 ratio of sugar to potassium nitrate.

Process Description

The simulation of potassium nitrate production in Aspen Plus includes several stages:

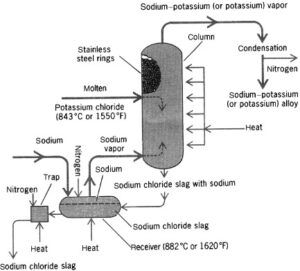

1. Process Flow Diagram (PFD) Design: The neutralization reaction between potassium hydroxide and nitric acid to produce potassium nitrate is outlined. The design incorporates reactor units, separators (such as crystallizers or evaporators), and dryers (if a solid product is produced).

2. Simulation Setup in Aspen Plus: A new simulation is created with the appropriate template. Chemical components, including potassium hydroxide, nitric acid, water, and potassium nitrate, are defined. A suitable thermodynamic model, such as ELECNRTL or NRTL, is selected. Operational units, including the reactor, crystallizer, separator, and dryer, are defined, along with operational conditions such as temperature, pressure, and feed flow rates. The simulation is executed and reviewed for errors.

3. Results Analysis: Mass and energy balances are verified. Phase equilibrium analysis for potassium nitrate recovery is conducted, and the purity of the final product is examined.

4. Optimization and Sensitivity Analysis: The feedstock ratios are adjusted to enhance production yield. The performance of the crystallizer is optimized to improve solid product recovery. The impacts of variations in temperature, pressure, and feed flow rates on production and product quality are assessed.

Conclusion

The simulation of the potassium nitrate plant in Aspen Plus serves as a powerful tool for analyzing and optimizing the production process. Considering the model’s limitations, the results of this simulation can provide useful guidance for improving unit performance or designing new facilities. This production unit is located in the Shiraz Industrial Town and is being executed as an EPCC project by the team at Anil Pars Process Industry Company, currently in operation.

Potassium Nitrate Unit Simulation with Aspen Plus

In this project, the simulation of potassium nitrate unit has been done in Aspen Plus software.