Introduction

Fluid transport through pipelines is a fundamental aspect of industrial processes in both chemical and mechanical engineering. Pressure drop in pipelines directly affects equipment performance, energy consumption, and operational costs. In this project, Aspen Plus software was utilized to simulate pressure drop in various pipelines for different water-air mixtures. This study enhances the understanding of fluid behavior in transport systems, identifies key factors influencing pressure drop, and optimizes pipeline design. Additionally, analyzing pressure drop under different scenarios allows engineers to predict system performance and make informed technical decisions.

Fundamental Concepts of Pressure Drop

Definition of Pressure Drop

Pressure drop in pipelines refers to the loss of fluid energy along the flow path, primarily due to friction and sudden changes in flow direction. This phenomenon significantly impacts the efficiency of industrial processes and plays a crucial role in optimizing pipeline design, selecting appropriate equipment, and reducing operational costs. Pressure drop is categorized into two types:

- Frictional Pressure Drop: Caused by friction between the fluid and the internal pipe surface. Factors such as pipe surface roughness, fluid viscosity, flow velocity, and pipe diameter influence frictional pressure drop.

- Local Pressure Drop: Occurs due to sudden changes in flow direction, such as pipe fittings, bends, diameter changes, and valves. Local pressure drop is typically calculated using empirical coefficients, aiding in better pipeline system design.

Methods for Calculating Pressure Drop

Calculating pressure drop in industrial systems is a complex process requiring empirical equations and numerical modeling. Several methods exist for pressure drop calculation, depending on system conditions and fluid type. Aspen Plus employs analytical and numerical approaches, including:

- Darcy-Weisbach Equation: A precise formula for calculating frictional pressure drop in pipes.

- Friction Factor: Depends on flow type (laminar or turbulent) and the relative roughness of the pipe’s internal surface. For turbulent flows, it is determined using the Moody Chart or empirical equations such as the Colebrook-White equation.

- Empirical Relations for Local Pressure Drop: Used for fittings, diameter changes, and valves, these coefficients are derived from industrial experiments and empirical data.

The pressure drop equations used in this study are referenced from Ludwig’s textbook on fluid flow.

Factors Affecting Pressure Drop

Several factors influence pressure drop, including:

- Flow Velocity: Higher velocity generally leads to greater frictional pressure drop.

- Fluid Density and Viscosity: Fluids with higher density and viscosity typically experience greater pressure drop.

- Pipe Diameter and Length: Larger diameters reduce pressure drop, while longer pipes increase it.

- Pipe Surface Roughness: Rougher surfaces increase friction, resulting in higher pressure drop.

Understanding pressure drop and its influencing factors is essential for optimizing pipeline design and selecting appropriate industrial equipment. Aspen Plus provides powerful analytical tools to accurately evaluate these phenomena, helping engineers optimize fluid transport systems. Proper pressure drop management can enhance process efficiency, reduce energy consumption, and improve overall system performance.

Simulation Methodology

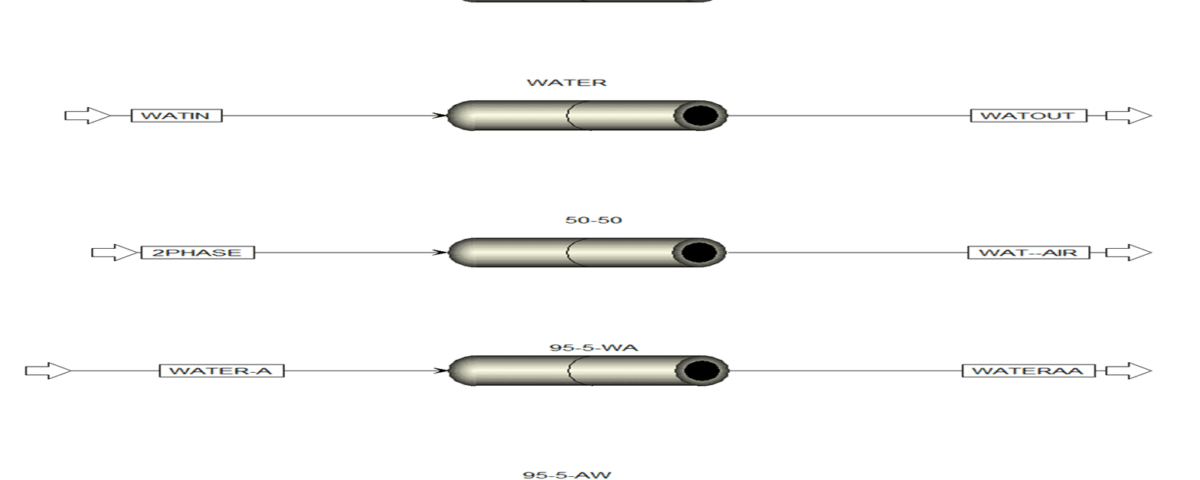

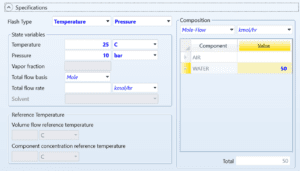

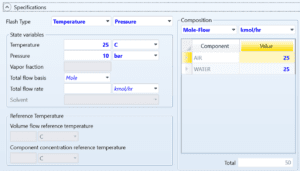

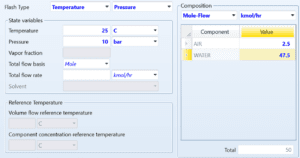

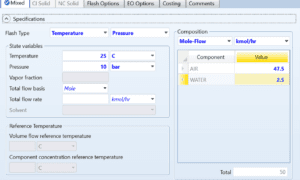

Aspen Plus software was used to analyze pressure drop in pipelines under different conditions and examine the effect of fluid composition on flow behavior. Five flow scenarios were considered:

Pure Air

Pure Water

Two-Phase (50% Water – 50% Air)

95% Water – 5% Air

5% Water – 95% Air

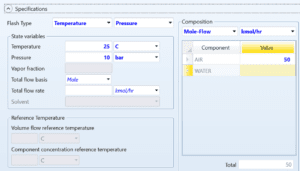

Thermodynamic Modeling

To model this system, the UNIFAC equation of state was used to describe the thermodynamic properties of mixtures. The UNIFAC model is widely recognized for predicting phase behavior and equilibrium in multi-component mixtures, providing accurate insights into phase separation in two-phase flow systems.

System Specifications and Operating Conditions

Pipeline Physical Parameters:

- Internal Diameter: 1.25 inches (≈ 31.75 mm)

- Pipe Length: 20 meters

Operating Conditions:

- Inlet Pressure: 10 bar

- Inlet Temperature: 25°C

- Mass Flow Rate: 50 kmol/h

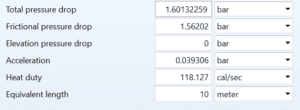

Pressure Drop Analysis Under Different Scenarios

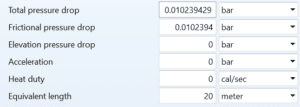

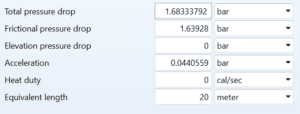

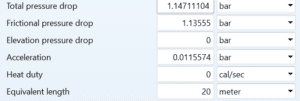

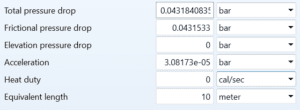

Simulation results indicate that pressure drop is significantly affected by fluid type and composition. Pure water exhibits the lowest pressure drop due to its higher density and viscosity, which stabilize flow. Pure air experiences the highest pressure drop due to its lower density and high compressibility, increasing flow resistance.

In two-phase flow conditions, pressure drop varies depending on the water-to-air ratio:

50% Water – 50% Air: Increased pressure fluctuations due to bubble formation and dispersed phase interactions.

95% Water – 5% Air: The system behaves similarly to pure water flow, with minor instabilities due to air presence.

5% Water – 95% Air: Pressure drop closely resembles pure air flow but is slightly modified by liquid droplets affecting friction and flow distribution.

Industrial Applications and Significance

Application in the Oil & Gas Industry

In oil and gas operations, pressure drop directly influences hydrocarbon transport rates, pump efficiency, and compressor performance. Optimized design using Aspen Plus minimizes undesirable pressure losses, enhances energy efficiency, and reduces extraction and processing costs.

Role of Pressure Drop in Petrochemical and Chemical Industries

In petrochemical processes, pressure drop control is essential for transporting raw materials and final products. Engineering software like Aspen Plus enables precise modeling of multiphase flows, pressure drop analysis, and the effect of factors such as pipe roughness, fluid temperature, and density. These insights help engineers determine optimal flow rates, pressure levels, and pipeline configurations.

Pipeline Optimization in Power Plants and Process Industries

In power plants, pressure drop affects water and steam transport systems. Accurate pressure drop calculations improve boiler efficiency, heat exchanger performance, and steam turbine operations. Proper pressure drop management enhances energy production efficiency, reduces fuel consumption, and optimizes equipment performance.

Conclusion

A thorough understanding of pressure drop and its influencing factors is critical for optimizing pipeline design and selecting suitable industrial equipment. Aspen Plus, as a leading engineering analysis tool, enables detailed evaluation of this phenomenon, allowing engineers to enhance fluid transport systems. This study demonstrates that pressure drop management improves process efficiency, reduces energy consumption, enhances system reliability, and extends equipment lifespan.