Introduction

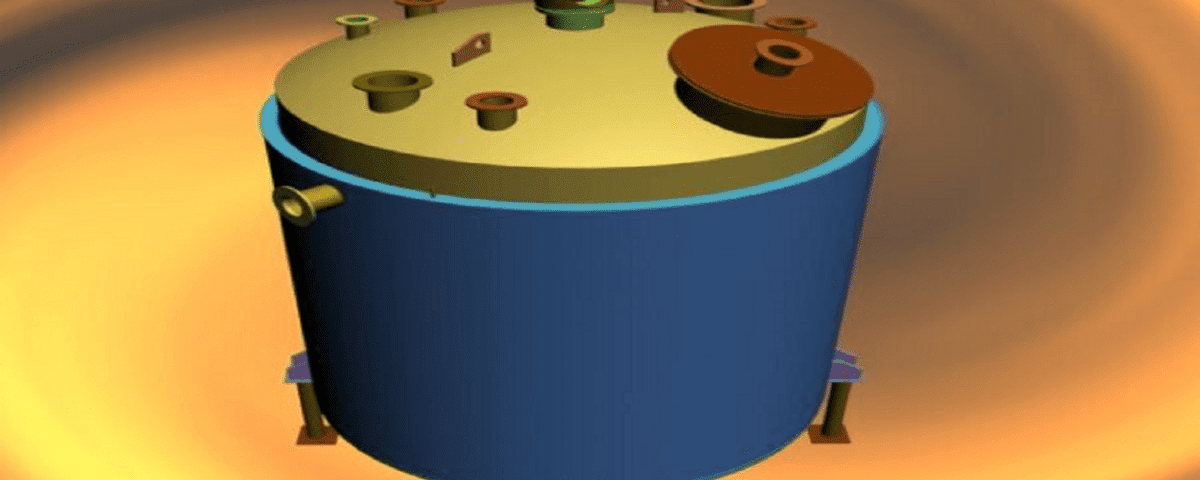

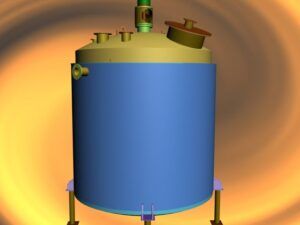

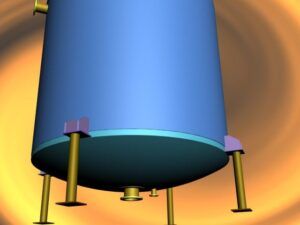

This project focuses on designing a 5000-liter reactor specifically for nitrate salts, using AutoCAD software. Constructed from stainless steel S.S 316L, this reactor offers exceptional resistance to corrosion and chemical stress, making it ideal for sensitive chemical processes. The design incorporates a thermal jacket, baffles, and a vertical mixer, enabling efficient temperature control and improved material mixing.

Features of the Nitrate Salts Reactor

The reactor is designed to hold 5000 liters, making it suitable for carrying out chemical reactions involving nitrate salts. Key features of the design include:

- Body Material: Stainless steel S.S 316L, chosen for its high resistance to corrosion and stability under heat and pressure.

- Thermal Jacket: Ensures precise temperature control and minimizes heat loss.

- Baffles: Enhance flow and thermal efficiency, promoting uniform mixing.

- Vertical Mixer: Guarantees consistent material mixing throughout reactions.

Provided Drawings and Design Files

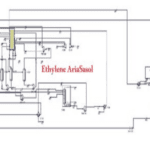

The project includes 13 detailed construction drawings in AutoCAD format, covering all key aspects of the equipment:

- General Layout

- Nuzzles & Supports Orientation Layout

- Nuzzles List

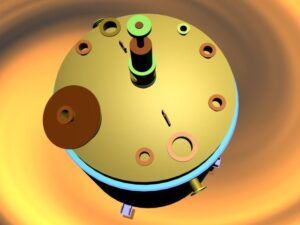

- Upper Head Design

- Reactor Upper Head

- Supports Connections Drawings & Details

- Supports Layout Plan

- Baffles Orientation Layout

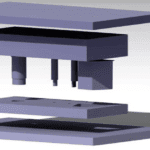

- Mixer Shaft Coupling System to Motor

- Mixer Drawing

- Lifting Lugs Details

- Nipples Jointing to Heads & Shell Details

Conclusion

This project, developed with industrial design standards in AutoCAD, serves as a valuable resource for designers and process engineers. The comprehensive drawings and detailed layout facilitate the manufacturing process, enhancing reactor efficiency in chemical plants. The reactor design, as part of advanced equipment for nitrate salts production, plays a crucial role in developing durable, corrosion-resistant equipment for the chemical industry.

Design Images of Nitrate Salts Reactor