Introduction

Natural gas supplies a large portion of the world’s growing energy demand, and this is likely to continue for several decades to come. Growing at twice the rate of oil, this trend indicates the important role that gas will play in the world’s future energy. Given the future scarcity of oil, the use of natural gas as an alternative energy source is a growing concern for scientists and engineers. Most of the world’s natural gas reserves are located in remote areas. In these areas, pipelines to bring natural gas to the market are not cost-effective. As a result, most natural gas is consumed in the country where it is produced.

Simulation of Natural Gas Dehydration Unit

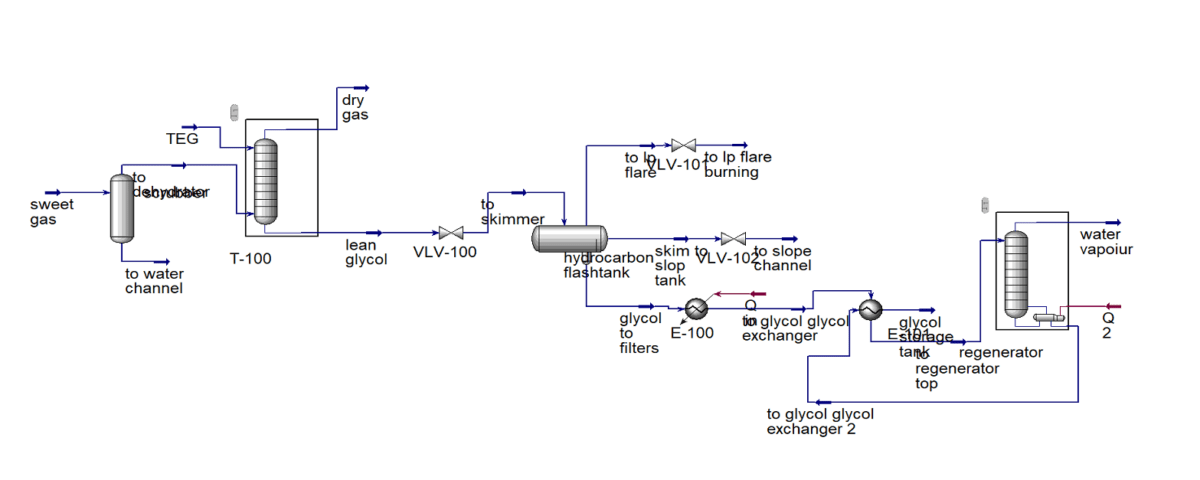

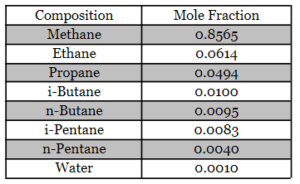

Specifically, the TEG-based dehydration process as shown in the absorption unit and the solvent (TEG) extraction as shown in the regeneration unit determine the required equipment needed for the plant modeling. The gas used is a semi-refined natural gas that has had bad components such as acid gas, mercury, and heavy hydrocarbons removed, as shown in the table below.

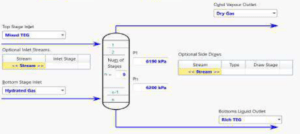

A combined fluid package (Glycol and Peng-Robinson) was used for HYSYS simulation, as it is commonly used for applications and studies of hydrocarbon systems. This specifically utilizes fugacity components, which handle the complex thermodynamics occurring during compression and are useful in both upstream and downstream industries. Separately, the gas then enters the absorber (contactor) from the bottom. The absorber operated with 9 stages for higher purity. The inlet of the TEG mixture and the outlet of the dry gas are located at the top of the column, while the outlet of the TEG and the inlet of the natural gas with hydrate (gas hydrate) are located at the bottom of the column. (As shown in the figure below)

Conclusion

Based on the results obtained from the optimization of the natural gas dehydration unit using TEG, it can be concluded that: the column pressure of the absorption column should be minimized to reduce the amount of hydrocarbons trapped in the wet TEG stream exiting from the bottom of the absorber. The number of theoretical trays in the TEG regenerator has little effect on the content of pure TEG. The minimum number of trays should be used. Natural gas dehydration simulation has also been performed by our company using Aspen Plus software and is available on our website.

Aspen HYSYS Simulation and Optimization of Natural Gas Dehydration Unit With Triethylene Glycol

In this project, the Aspen HYSYS simulation and optimization of the natural gas dehydration unit using triethylene glycol have been carried out using Aspen HYSYS version 14.