Introduction

Evaporator is one of the key equipments in evaporation and concentration processes. The evaporator is responsible for separating volatile substances (such as water) from non-volatile substances (such as aqueous solutions). Using thermal energy, this equipment separates the incoming solution into steam and condensed liquid. The design of the evaporator should be such that, while increasing the concentration of the product, the decomposition or destruction of sensitive materials is prevented.

There are different types of evaporators which are classified based on the heat transfer method, operating pressure and number of stages. Multi-stage evaporators are widely used due to energy recovery and increased energy efficiency. In this type of evaporators, the solution is condensed step by step in several stages, and the heat of evaporation of the next stages is provided by the steam emitted from the previous stages.

Evaporator design includes the calculation of parameters such as heat exchanger surface, steam and water flow rate, temperature and pressure in each stage. Also, determining the type and dimensions of heat exchangers and auxiliary systems such as heating and cooling systems are considered important stages of evaporator design. This design should be done considering process, economic and environmental factors.

How do Evaporator Design Steps Affect its Performance?

Evaporator design steps directly affect the performance of this equipment. The main components of the evaporator design that affect its efficiency are:

1. Calculation of the heat exchanger surface: The size of the heat exchanger surface determines the amount of heat transfer and the thermal efficiency of the evaporator. The design of adequate heat exchanger surface increases efficiency and reduces energy consumption.

2. Steam and water flow rate calculation: Determining the production steam flow rate and condensed water output has a great impact on the proper operation of the evaporator. These parameters should be calculated according to the needs of the process.

3. Determining the temperature and pressure in each step: The correct setting of temperature and pressure in each step of evaporation affects the quality of the final product. The design of these parameters should be done according to process conditions and equipment limitations.

4. Choosing the type and dimensions of heat exchangers: using suitable heat exchangers with appropriate dimensions helps to increase evaporation efficiency and reduce energy consumption.

5. Design of auxiliary systems: heating, cooling, control systems, etc., their proper design improves the overall efficiency and performance of the evaporator.

In general, accurate design and appropriate to the process, equipment and environmental conditions play an important role in optimizing the performance of the evaporator.

Evaporator Design with ASPEN EDR Software

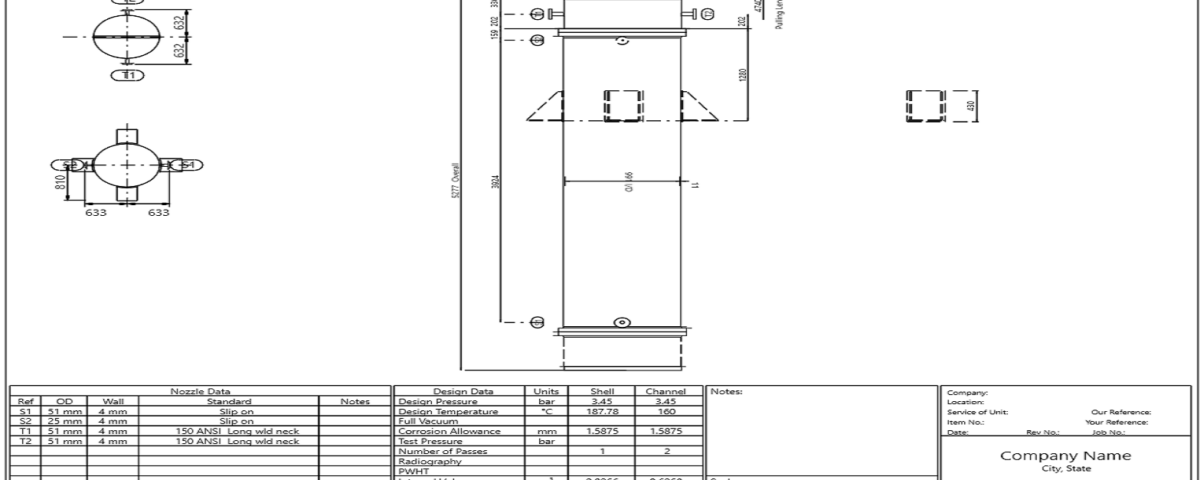

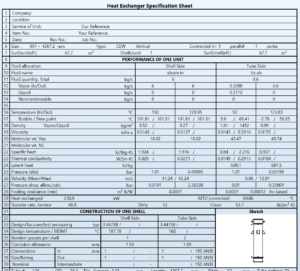

The precise design of NaOH evaporator and concentrator requires specialized knowledge in different fields of chemical engineering, mechanics and heat transfer. This process must be carried out with high precision and sensitivity so that optimal efficiency and safety and environmental standards are met. Relying on deep technical knowledge, Anil Pars Company is able to offer NaOH evaporator design. The figure below presents the output results obtained from ASPEN EDR for this design.

Evaporator and Concentrator Design for NaOH Unit

In this project, the evaporator and Concentrator Design for NaOH unit and its simulation has been done in Aspen EDR software.

.