Introduction

In the realm of chemical engineering and materials processing, elbow mixing (Elbow) is recognized as a vital component in fluid transport and mixing systems. This element effectively facilitates the flow of fluids through angles and directional changes, playing a crucial role in enhancing mixing processes. Given the complexity of dynamic flow behavior within elbows and its impact on the quality and efficiency of final products, simulating elbow mixing in specialized software such as ANSYS Fluent and COMSOL has gained attention as an effective method for examining and analyzing these processes. These simulations, by providing accurate models and comprehensive technical data, assist engineers in optimizing the design and performance of industrial systems. Overall, it is one of the most efficient elbow connections produced at angles of 45 and 90 degrees. Fluent is one of the world’s most powerful software, modeling various flows using the finite volume method (FVM).

Process Description

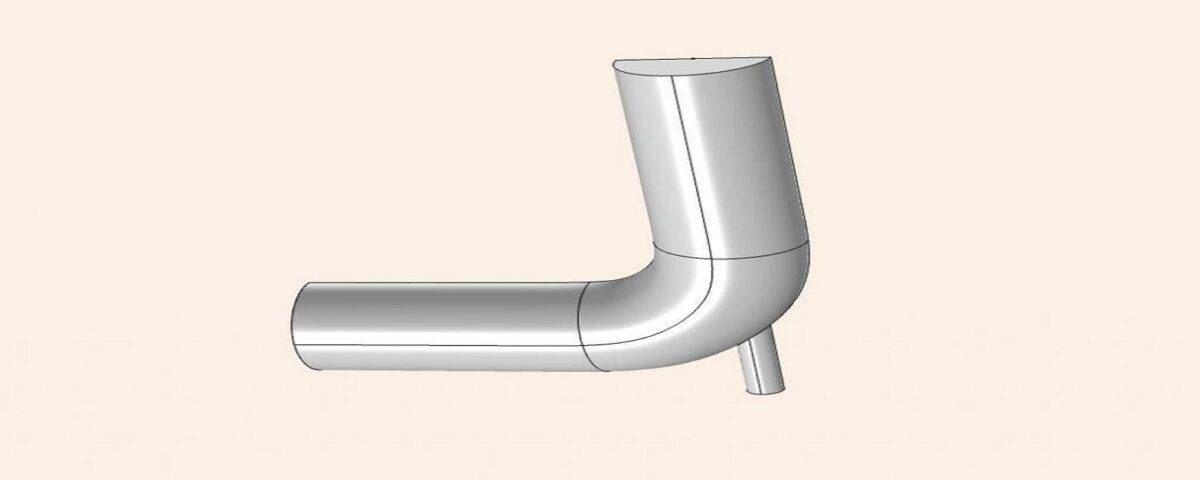

The simulation of elbow mixing in ANSYS Fluent and COMSOL involves several key steps that analyze the flow and mixing of two or more phases within this structure. Initially, the geometry of the elbow is accurately designed, and the physical and chemical properties of the fluids are defined. In this step, CAD tools can be utilized to create the geometric model. Next, an appropriate computational mesh is generated for the simulation to enhance calculation accuracy. Subsequently, boundary and initial conditions such as inlet velocity, temperature, and pressure are set.

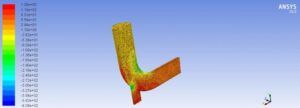

Following this, the simulation is executed based on the governing equations of flow and heat transfer. ANSYS Fluent allows the use of various turbulence and multiphase models, while COMSOL offers the capability to perform diverse simulations, including coupled physics that simultaneously examine thermal and mechanical effects. Finally, the results of these simulations, including flow distribution, mixing characteristics, and pressure and temperature profiles, are analyzed to gain a better understanding of elbow mixing performance and optimize its design.

In this project, the fluid flow inside a mixing elbow is simulated with the help of AnsysFluent and Comsol software.

Conclusion

In conclusion, the simulation of elbow mixing in ANSYS Fluent and COMSOL serves as a fundamental tool for gaining a deeper understanding of flow behavior and mixing in multiphase systems. The insights gained from these analyses can lead to reduced costs, lower energy consumption, and enhanced quality of industrial processes. Accurate modeling of an elbow using both ANSYS Fluent and COMSOL is essential for achieving optimal design outcomes and operational performance.

Modeling an elbow in a completely accurate way in 2 Ansys Fluent and Comsol software.