Introduction

Methanol is one of the three most important products of chemical industries in the world and many substances are derived from it. Methanol is one of the products of the petrochemical industry in the country, which the non-governmental sector seeks to develop their capacity with a special focus. In this project, the production of methanol from carbon dioxide and hydrogen gas has been investigated.

At first, the production methods of this material have been investigated and the synthesis process of methanol from recycled CO2 gas has been investigated. The ratio of empty capacity of methanol producing petrochemicals in the world to their current supply is about 65%. And this means the presence of excess capacity in methanol production up to 1.65 times if there is methanol consumption infrastructure in the world. Ease of access to natural gas feed, marine transportation lines, and having product storage facilities and loading docks for product export. Access to open water is one of the most important advantages and characteristics of methanol producing companies in the country. Currently, methanol is produced in four petrochemical complexes in the country.

Methanol Production

The volume of methanol production in the country in Shiraz, Khark, Fanaveran and Zagros Petrochemicals is 84, 660, 1000 and 3300 thousand tons, respectively. Of course, the methanol production units are implementing the development plan, which will greatly increase the volume of production with the implementation of this project. China, Japan, Azerbaijan, Slovenia, Afghanistan, Italy, Belgium, Thailand, Taiwan, South Korea, Sri Lanka, Iraq, Egypt, Netherlands and India are among the customers of Iran methanol industry. China has been introduced as the growth engine of methanol demand in the world.

Considering the large investments made in this industry and the prediction of the operation of new methanol production plants by 2022, China will not depend on imports to meet its domestic needs. Therefore, China first place in both methanol production and consumption has made this Asian country able to have a greater impact on this industry. Currently, the countries of the Middle East region are the largest producers and exporters of methanol due to the availability of abundant and cheap natural gas.

Description of The Process

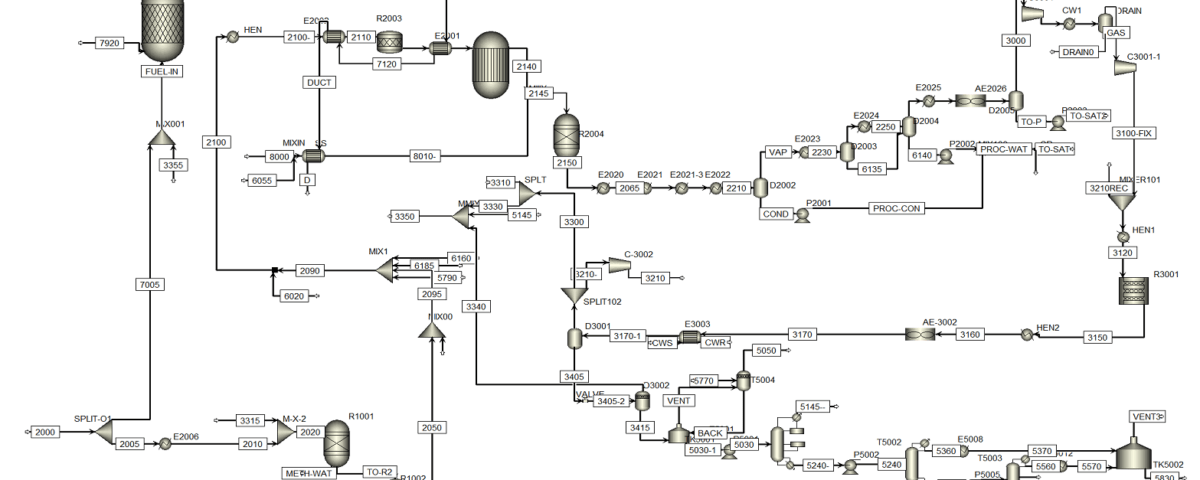

All the required information is used from Marjan petrochemical industrial documents, which were designed and implemented under the license of Namvaran company. The simulation of the process has been done from page 1 of the petrochemical PFD industrial maps to the separation towers and methanol storage tanks.

The process designed in this petrochemical unit has the following steps:

Desulfurization

Gas saturation with process condensate

Adiabatic pre-reforming

Catalytic reforming in a tubular reactor

Reforming auto-heating reactor (AutoThermal)

Synthesis gas cooling network

Methanol synthesis

Distillation and purification of methanol

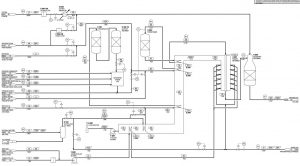

The full description of the above processes is available in full details in industrial documents. If you need information, refer to Operation Manual, PFD, PID sources. In this project, Marjan petrochemical methanol process is simulated using Aspen Plus software. And all its information has been examined from industrial maps and its simulation has been adapted with industrial information.

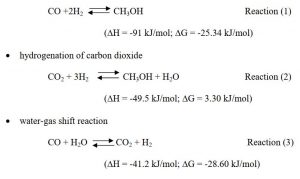

The low percentage of simulation error shows the correct method of simulating this process and models and assumptions. In this synthetic simulation, methanol production reactions are taken from the following article.

Click on the link below to download the article.

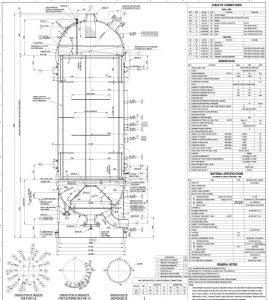

Part of Industrial Documents Equipment Data-Sheet Marjan Petrochemical Methanol Reactor

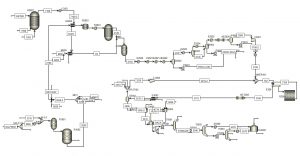

Part of The Methanol Unit PFD

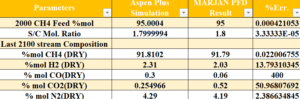

Simulation of Marjan Petrochemical Methanol Unit

The table presented below shows part of the simulation results of Marjan Petrochemical Methanol Unit. These data are usually generated in industrial process simulation software such as Span Plus. and are used to evaluate unit performance, process optimization, and compare results with actual data. The error percentage of most of the parameters is very low, which indicates that the simulation results are in good agreement with the values designed for the unit.

This indicates the accuracy of the simulation model and the correctness of the input parameters to the model. In short, the presented table provides valuable information about the performance of Marjan Petrochemical Methanol Unit. By analyzing these data, a better understanding of the methanol production process and the challenges associated with it can be achieved. Also, this data can be used to improve unit performance and optimize the production process.

Marjan Petrochemical Methanol Unit was carried out by SANILCO in the following three ways.

1. Full simulation of Marjan petrochemical methanol unit

2. Conceptual design of a new process to produce synthesis gas, hydrogen and absorb carbon dioxide

3. Comparison of synthesis and industrial gas production process of Marjan Petrochemical Methanol Unit

Full Simulation of Marjan Pet. Co. Methanol Unit With Aspen Plus

In this project, the complete simulation of Marjan petrochemical methanol unit is simulated in Aspen Plus software. In addition to the simulation files, this project also has a full report and training video.