Introduction

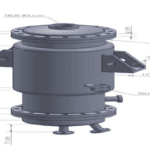

A bag filter is an industrial filtration device used to separate solid particles from gas streams. It consists of a housing containing numerous fabric or fiber bags through which the contaminated gas passes. Solid particles in the gas adhere to the surface of the bags, while the cleaned gas exits from the other end of the filter.

Industrial Design of Bag Filters

A bag filter is a chamber containing a number of polyester bags. As the gas containing dust passes through the inlet and moves towards the filter outlet, the dust settles on the outer surface of the bags. At regular intervals, a pulse of air is applied to shake the dust off the bag and into the hopper below. This separates the dust from the gas. Bag filters are widely used for dust removal in the cement industry due to their high dust removal efficiency, which can reach up to 99.9% depending on the type of dust.

Advantages and Disadvantages

- Advantages: High efficiency in particle removal, wide range of applications, low maintenance costs, flexible design.

- Disadvantages: Sensitivity to high humidity and temperature, potential for bag clogging, risk of explosion if combustible particles are present.

Applications

- Industrial air filtration: Removal of dust, soot, and other particles from gas streams in various industries.

- Air pollution control: Reduction of air pollution emissions from industries.

- Building ventilation: Filtration of incoming air to buildings and removal of pollutants such as dust and pollen.

- Recovery of valuable particles: Recovery of valuable particles such as metals from gas streams.

Factors Affecting Bag Filter Performance

- Fabric type: The type of fabric used for the bags affects the filter’s efficiency, abrasion resistance, and service life.

- Gas flow rate: Increasing the gas flow rate can reduce filter efficiency.

- Dust concentration: Increasing the dust concentration in the gas stream increases the rate of bag clogging.

- Particle size: Smaller particles can more easily penetrate the pores of the bags, reducing filter efficiency.

- Humidity and temperature: High humidity and temperature can negatively impact filter performance.

The following factors play a crucial role in the performance of bag filters:

- Material of the filter bags: The type of material used for the bags significantly impacts their durability, efficiency, and compatibility with different types of dust.

- Dust collection area: The surface area of the filter bags directly influences the amount of dust that can be collected.

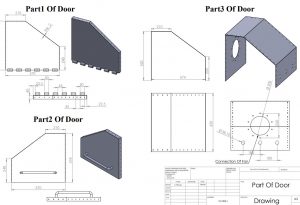

- Bag structure and shape: The design of the bags, including their shape and configuration, affects the filtration process and cleaning efficiency.

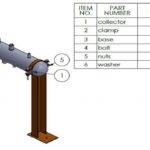

- Dust removal system: The method used to clean the bags, such as reverse air jet or mechanical shaking, impacts the overall performance of the filter.