Description

The gas sweetening refinery is one of the facilities of the Amak oil gas collection project. which sweetens sour gasses with oil in Timur, Maron, Ahvaz and Kopal water fields. Amak sweetening refinery is located 15 kilometers east of Ahvaz and was put into operation in 2014.

Amak project is a plan to collect gases associated with several oil fields and prevent the release of pollutants. At present, sour gases with oil produced in Bangestan reservoir are burned in Timur, Mansouri, Maron Ahvaz and Kopal water fields due to the lack of necessary facilities. Amak project is implemented in order to collect and use these gases and prevent waste and pollution of the environment. The word Amak is made by connecting the first letters, Timur water, Mansoori, Maron, Ahvaz and Kopal.

General Objectives of AMAK Refinery

Preventing the burning of sour gas with oil and preventing the release of pollutants.

Production of sweet gas liquids (NGL)

Production of sweet light gas for industrial use

Increasing the production capacity of crude oil through the return of sour gas liquids in gas compression stations to exploitation units

Transfer of separated acid gases in the design sweetening refinery to RAZI Petrochemical for processing and producing sulfur for export.

Amak Sweetening Refinery

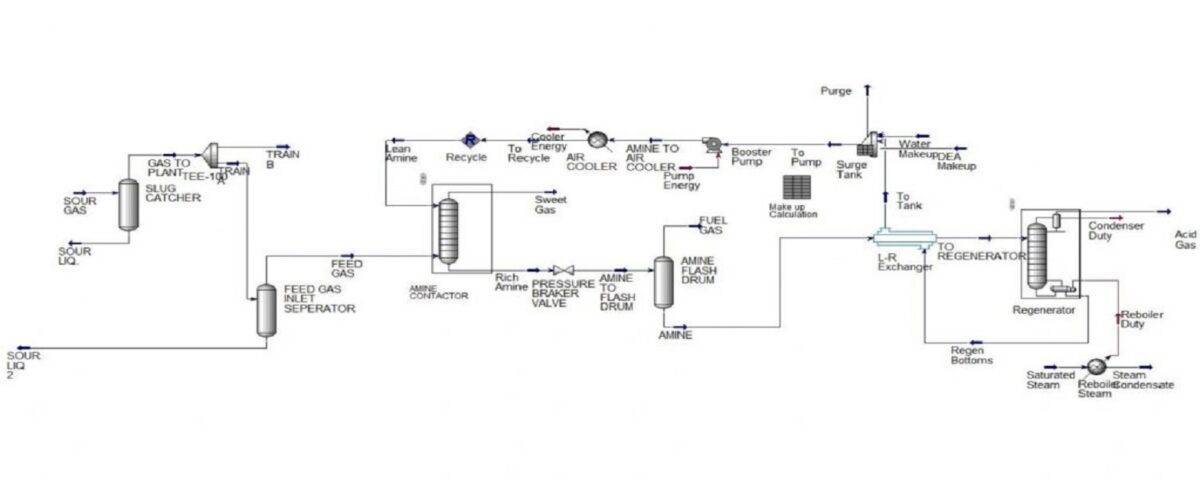

This refinery has been built near 800/700 gas and liquefied gas factories. The incoming dry gases are collected by several inlets and directed to the inlet Slug Catchers and then sent to two similar rows of the sweetening unit.

In the absorption tower, the incoming sour gas is placed in contact with the diethanolamine (DEA) solution. And acid gases and sulfur compounds are reduced. The output sweet gas is sent to gas and liquid gas factories 700 and 800.

In this project, the simulation of sweetening unit (with DEA) of Amak Refinery has been done in Aspen Hysys software.